Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

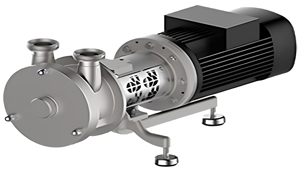

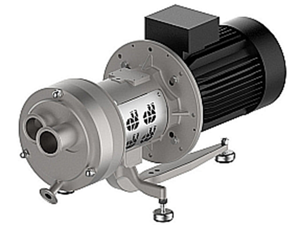

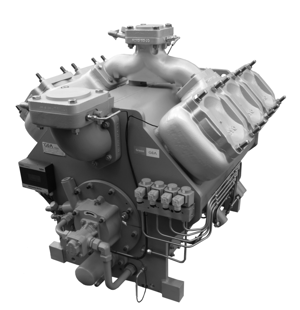

Manual for GEA Hygienic Pump Hilge SIPLA 12.1

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

GEA Hygienic Pump Hilge SIPLA 12.1

Create an account to install this asset package.

Maintenance Plans for GEA Hygienic Pump Model Hilge SIPLA 12.1

Integrate maintenance plans directly into your work orders in MaintainX.

Hygienic Pump Inspection

Commissioning

Functional testing of the mechanical seal

Inspect the pump and check whether liquid exits at the mechanical seal

An intact mechanical seal operates virtually without any leakage

If pumped fluid or flushing fluid exits

Switch off the pump

Replace the mechanical seal

Follow the installation instructions Section 10.2, Page 44

Hygienic Pump Check

All connections are firmly secured

All safety devices are installed

Electrical connections are correct

Pipe system on the installation side is clean

Stop valves in the system are open

Pump and system are filled

Pump and system are vented

Flushing fluid is connected for double mechanical seal / quench version

Suction-side stop valve is fully open

Hygienic Pump Cleaning

Warning: This cleaning procedure requires trained personnel with PPE!

Cleaning is carried out inside the system no parts need to be removed or dismantled.

In general, a distinction is made between CIP and SIP. The procedures must comply with the state of the art and the EC directives.

Safety notes

Use only suitable cleaning agents.

Observe the safety instructions in the product descriptions of the cleaning agents.

Use always suitable personal protective equipment when handling cleaning agents.

Be sure to avoid exceeding the permissible concentrations of cleaning agents.

Reducing acids should not be used, because they cause pitting.

Motor Maintenance

Maintenance of the motor

Motors without grease nipple

Motors without grease nipple are equipped with lifetime lubrication.

The grease life then depends on the bearing life.

Prerequisite is that the motor must be used according to the specifications in the catalogue.

Motors with grease nipple

On motors with grease nipple, the specifications for relubrication, type of grease, grease quantity, and other information as applicable are given on the lubrication or type plate.;

2000 Hourly Pump Inspection

Warning: This inspection requires trained personnel with PPE!

Visual inspection of the pump for any malfunctions

Check for leak tightness

Check for correct functioning of the pump

Enter the pump's hour meter reading

Check wear parts such as the mechanical seal and O-rings after 2000 hours of operation

Were any parts replaced?

List the parts that were replaced

Sign off on the pump inspection

Parts for GEA Hygienic Pump Hilge SIPLA 12.1

Access the parts list for your equipment in MaintainX.

Pump Housing

0101

Suction Nozzle

0153

Pressure Nozzle

0156

Dome Stand

0180

Bearing Support

0330

Pump Housing

0101

Suction Nozzle

0153

Pressure Nozzle

0156

Dome Stand

0180

Bearing Support

0330

Pump Housing

0101

Suction Nozzle

0153

Pressure Nozzle

0156

Dome Stand

0180

Bearing Support

0330

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX