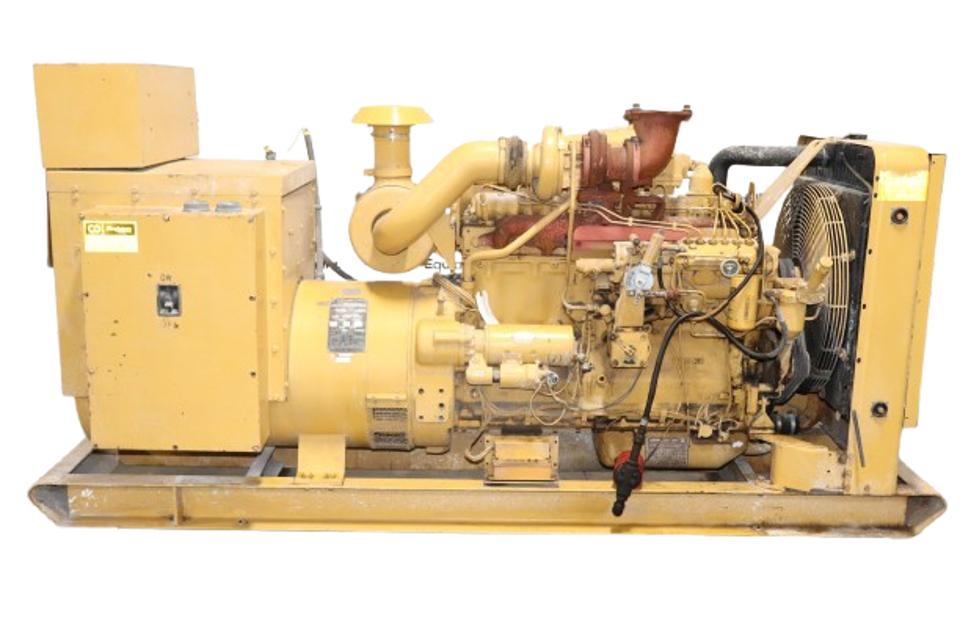

The Caterpillar HV Generator SR-4 is a robust industrial generator designed for high-performance applications. Known for its reliability and efficiency, this generator model is ideal for various power generation needs in industrial settings, ensuring optimal operation and minimal downtime.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Caterpillar HV Generator SR-4

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Caterpillar HV Generator SR-4

Create an account to install this asset package.

Maintenance Plans for Caterpillar HV Generator Model SR-4

Integrate maintenance plans directly into your work orders in MaintainX.

Generator Set Functional Test

Tools needed: 6V-7070 Digital Multimeter 1pc, 12 V DC Battery 1pc

Warning: Do not operate the generator set at more than half of rated speed. Higher speeds, under the conditions of this test can cause damage to the system

Disconnect wires F1 and F2 from the voltage regulator. Disconnect the generator from load

Connect a 12 V DC automotive type battery to wires F1 + and F2 -

Operate the generator set at half the rated speed

Measure and record the AC voltage across the following terminals: T1 and T2

Measure and record the AC voltage across the following terminals: T1 and T3

Measure and record the AC voltage across the following terminals: T2 and T3

Monitor the same voltages as Step 4, while decreasing and then increasing the generator set speed 10%. Do not exceed half of rated speed

18000 Hours / 3 Yearly Generator Maintenance

- Remove generator outlet box cover. Visually inspect stator output leads

- Visually inspect stator output leads, protective sleeving and insulation for cracking or physical damage. (Same as 7500/9000 hour check)

- Check all exposed electrical connections for tightness

- Check transformers, fuses, capacitors and lightning arrestors for loose mounting or physical damage

- Check all lead wires and electrical connections for proper clearance and spacing

- Check insulation resistance to ground on all generator windings

A. Main rotating assembly

B. Main stator assembly

C. Exciter and PMG stationary fields

Brushless Exciter Rotating Rectifier Ohmmeter Test

Warning: This procedure requires trained personnel with PPE!

Failure of a rectifier suspected?

If a failure of a rectifier is suspected, proceed with the following steps

Exciter cover removed?

Rectifier removed from heat sink?

Ohmmeter leads connected across rectifier in one direction?

Meter reading in one direction

Ohmmeter leads reversed and connected across rectifier in the other direction?

Meter reading in the other direction

Generator Maintenance

- Inspect Ground Insulation

Ground insulation is generally defined as that insulation intended to isolate the current carrying components from the noncurrent bearing components

- Inspect Support Insulation

Support insulation, such as block, slot wedges, etc. are usually made from compressed laminates of fibrous materials, polyester or similar felt pads impregnated with various types of bonding agents

- Inspect for Deterioration Or Degradation Of Insulation From Thermal Aging

Examination of coils reveal general puffiness, swelling into ventilation ducts or a lack of firmness of the insulation, suggesting a loss of bond with consequent separation of the insulation layers from themselves or from the winding conductors or turns

- Inspect for Abrasion

Coil and connection surfaces may be damaged by abrasion or contamination from other sources, such as chemicals or abrasive or conducting substances

- Inspect for Cracking

7500 Hours / 1 Yearly Generator Maintenance

Generator Outlet Box Maintenance

Remove generator outlet box cover

Visually inspect stator output leads, protective sleeving and insulation for cracking or physical damage

Check all exposed electrical connections for tightness

Check transformers, fuses, capacitors and lightning arrestors for loose mounting or physical damage

Check all lead wires and electrical connections for proper clearance and spacing

Generator Windings Inspection

Check insulation resistance to ground on main rotating assembly

Check insulation resistance to ground on main stator assembly

Parts for Caterpillar HV Generator SR-4

Access the parts list for your equipment in MaintainX.

Hammer, Soft-Faced

1S-0258

Lamp - Fluorescent, Safety Light

4C-6477

Megger, To Measure Insulation Resistance

9U-6003

Digital Thermometer, For Measuring Temperature In Degrees Celsius

4C-6500

Grease Gun, For Lubricating Bearings

8F-9866

Hammer, Soft-Faced

1S-0258

Lamp - Fluorescent, Safety Light

4C-6477

Megger, To Measure Insulation Resistance

9U-6003

Digital Thermometer, For Measuring Temperature In Degrees Celsius

4C-6500

Grease Gun, For Lubricating Bearings

8F-9866

Hammer, Soft-Faced

1S-0258

Lamp - Fluorescent, Safety Light

4C-6477

Megger, To Measure Insulation Resistance

9U-6003

Digital Thermometer, For Measuring Temperature In Degrees Celsius

4C-6500

Grease Gun, For Lubricating Bearings

8F-9866

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX