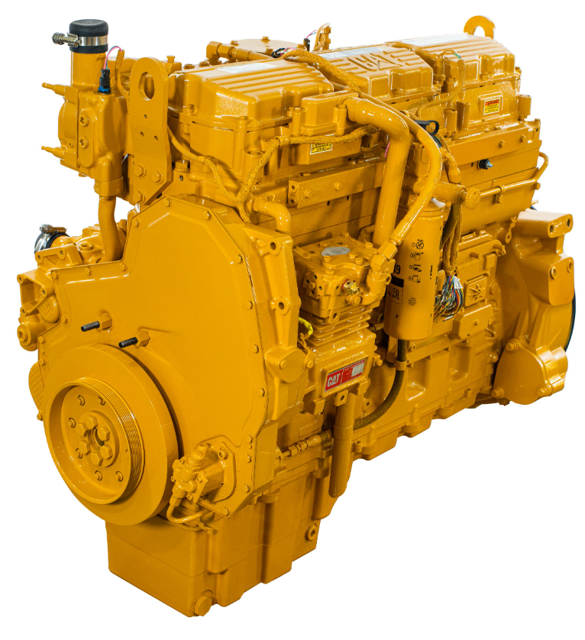

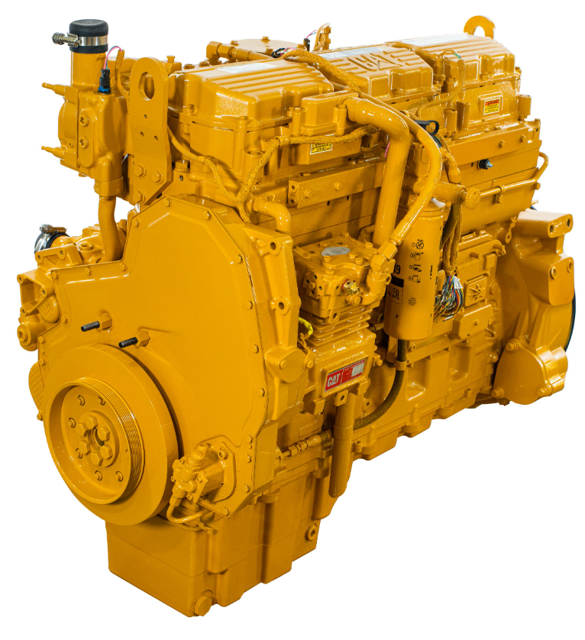

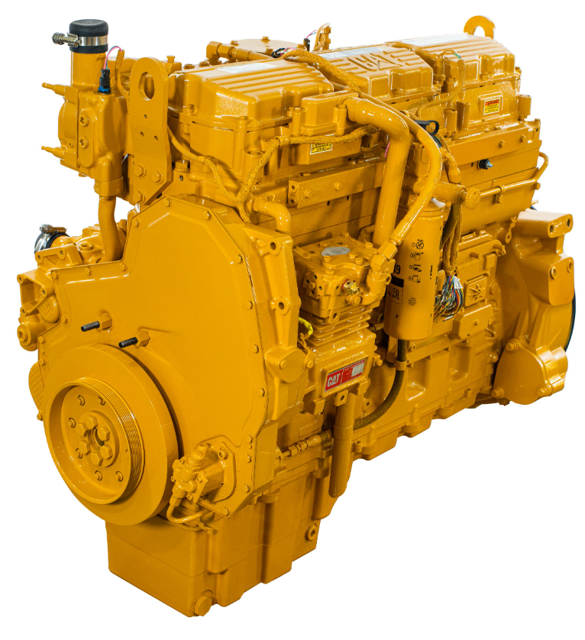

The Caterpillar C-12 engine is a robust industrial engine known for its reliability and performance. Ideal for various applications, this engine model offers efficient power delivery and durability, making it a preferred choice for heavy-duty operations. Regular maintenance ensures optimal performance and longevity.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Caterpillar Engine C-12

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Caterpillar Engine C-12

Create an account to install this asset package.

Maintenance Plans for Caterpillar Engine Model C-12

Integrate maintenance plans directly into your work orders in MaintainX.

Initial 20 Hours Engine Maintenance

Belt - Inspect

Inspection

Belt tension should be checked initially between the first 20 to 40 hours of engine operation.

Adjustment

Alternator Belt

Sign off on the engine maintenance

250 Hourly Engine Maintenance

WARNING: Be sure the engine cannot be started while this maintenance is being performed. To prevent possible injury, do not use the starting motor to turn the flywheel.

Hot engine components can cause burns. Allow additional time for the engine to cool before measuring/adjusting the unit injectors.

The electronic unit injectors use high voltage. Disconnect the unit injector enable circuit connector in order to prevent personal injury. Do not come in contact with the injector terminals while the engine is running.

Electronic Unit Injector - Inspect/Adjust

Adjust the electronic unit injector at the same interval as the valve lash adjustment. The operation of Caterpillar engines with improper adjustments of the electronic unit injector can reduce engine efficiency. This reduced efficiency could result in excessive fuel usage and/or shortened engine component life.

Engine Valve Lash - Inspect/Adjust

The initial valve lash adjustment on new engines, rebuilt engines, or remanufactured engines is recommended at the first scheduled oil change.

Only qualified service personnel should perform this maintenance. Refer to the Service Manual or your Caterpillar dealer for the complete valve lash adjustment procedure.

Operation of Caterpillar engines with improper valve adjustments can reduce engine efficiency. This reduced efficiency could result in excessive fuel usage and/or shortened engine component life.

2000 Hourly / 1 Yearly Engine Maintenance

Aftercooler Core - Clean/Test

Remove the core. Refer to the Service Manual for the procedure.

Turn the aftercooler core upside-down to remove debris.

NOTICE: Do not use a high concentration of caustic cleaner to clean the core. A high concentration of caustic cleaner can attack the internal metals of the core and cause leakage. Only use the recommended concentration of cleaner.

Back flush the core with cleaner.

Caterpillar recommends the use of Hydrosolv liquid cleaner. Table 37 lists Hydrosolv liquid cleaners that are available from your Caterpillar dealer.

Steam clean the core to remove any residue. Flush the fins of the aftercooler core. Remove any other trapped debris.

Wash the core with hot, soapy water. Rinse the core thoroughly with clean water.

WARNING: Personal injury can result from air pressure. Personal injury can result without following proper procedure. When using pressure air, wear a protective face shield and protective clothing. Maximum air pressure at the nozzle must be less than 205 kPa (30 psi) for cleaning purposes.

When required Engine Maintenance

Battery - Replace

WARNING: Batteries give off combustible gases which can explode. A spark can cause the combustible gases to ignite. This can result in severe personal injury or death.

Ensure proper ventilation for batteries that are in an enclosure. Follow the proper procedures in order to help prevent electrical arcs and/or sparks near batteries. Do not smoke when batteries are serviced.

The battery cables or the batteries should not be removed with the battery cover in place. The battery cover should be removed before any servicing is attempted.

Removing the battery cables or the batteries with the cover in place may cause a battery explosion resulting in personal injury.

Turn the key start switch to the OFF position. Remove the key and all electrical loads.

Turn OFF the battery charger. Disconnect the charger.

The NEGATIVE “-” cable connects the NEGATIVE “-” battery terminal to the ground plane. Disconnect the cable from the NEGATIVE “-” battery terminal.

The POSITIVE “+” cable connects the POSITIVE “+” battery terminal to the starting motor. Disconnect the cable from the POSITIVE “+” battery terminal.

6000 Hourly / 6 Yearly Engine Maintenance

Cooling System Coolant (ELC) - Change

Engine overheats frequently?

Foaming observed?

Oil has entered the cooling system and the coolant is contaminated?

Fuel has entered the cooling system and the coolant is contaminated?

Drain

Engine stopped and cooled?

Cooling system filler cap removed?

Cooling system drain valve opened or cooling system drain plugs removed?

Parts for Caterpillar Engine C-12

Access the parts list for your equipment in MaintainX.

Hydrosolv 4165 208 L (55 US gallon)

8T-7570

Hydrosolv 100 208 L (55 US gallon)

8T-5571

Caterpillar Liquid SCA 0.47 L (16 oz)

8T-1589

Caterpillar Liquid SCA 0.94 L (32 oz)

3P-2044

Hydrosolv 100

1U-5492

Hydrosolv 4165 208 L (55 US gallon)

8T-7570

Hydrosolv 100 208 L (55 US gallon)

8T-5571

Caterpillar Liquid SCA 0.47 L (16 oz)

8T-1589

Caterpillar Liquid SCA 0.94 L (32 oz)

3P-2044

Hydrosolv 100

1U-5492

Hydrosolv 4165 208 L (55 US gallon)

8T-7570

Hydrosolv 100 208 L (55 US gallon)

8T-5571

Caterpillar Liquid SCA 0.47 L (16 oz)

8T-1589

Caterpillar Liquid SCA 0.94 L (32 oz)

3P-2044

Hydrosolv 100

1U-5492

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX