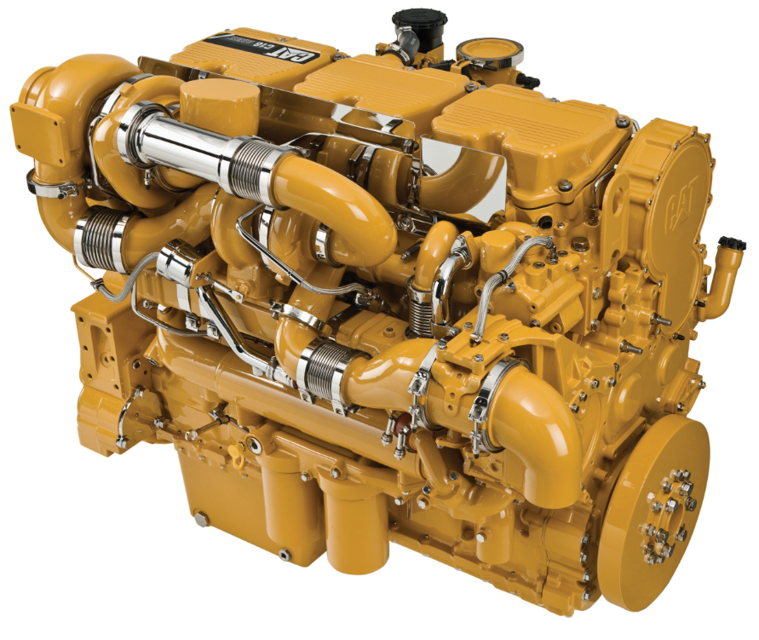

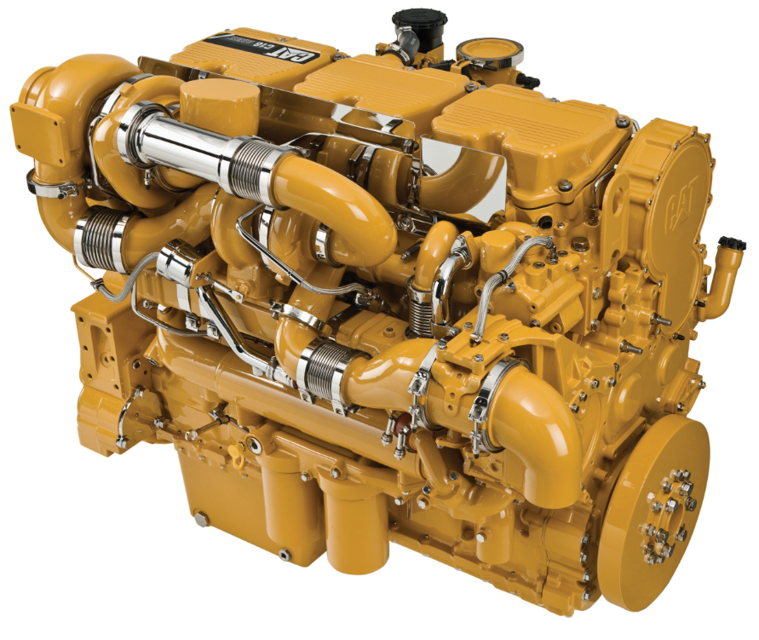

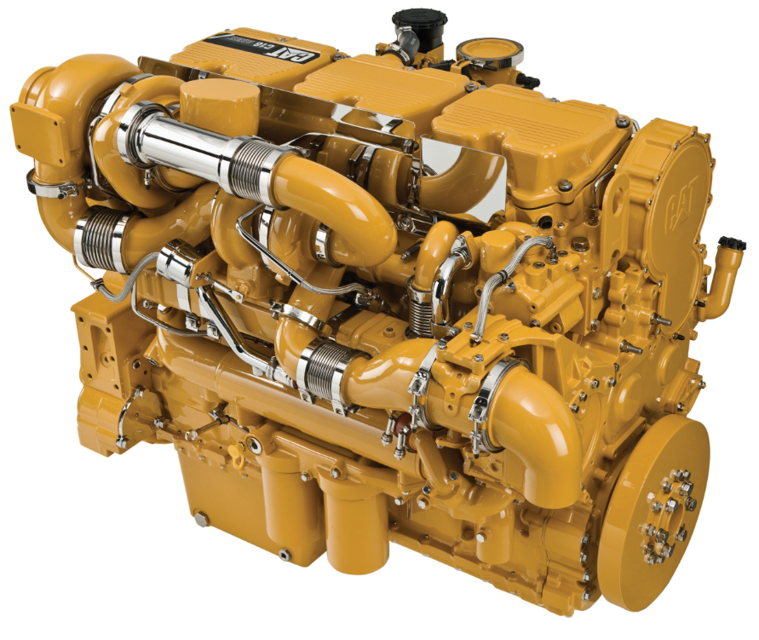

The Caterpillar Diesel Engine C18 is a robust industrial engine known for its reliability and efficiency. Designed for heavy-duty applications, this engine model offers exceptional performance and durability, making it a preferred choice in various industries. Regular maintenance ensures optimal operation and longevity of the C18 engine.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Caterpillar Diesel Engine C18

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Caterpillar Diesel Engine C18

Create an account to install this asset package.

Maintenance Plans for Caterpillar Diesel Engine Model C18

Integrate maintenance plans directly into your work orders in MaintainX.

250 Hourly Mini Hydraulic Excavator Maintenance

WARNING: Cooling system coolant additive contains alkali. To help prevent personal injury, avoid contact with the skin and eyes. Do not drink cooling system coolant additive.

NOTICE: Excessive supplemental coolant additive concentration can form deposits on the higher temperature surfaces of the cooling system, reducing the engine’s heat transfer characteristics. Reduced heat transfer could cause cracking of the cylinder head and other high temperature components.

NOTICE: Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids.

Note: Caterpillar recommends an S·O·S coolant analysis (Level 1).

Test the Concentration of the SCA

Pressurized System: Hot coolant can cause serious burns. To open the cooling system filler cap, stop the engine and wait until the cooling system components are cool. Loosen the cooling system pressure cap slowly in order to relieve the pressure.

Remove the cooling system filler cap slowly.

If necessary, drain some coolant in order to allow space for the addition of the SCA.

Add the proper amount of SCA.

12000 Hourly or 6 Yearly Mini Hydraulic Excavator Maintenance

Cooling System Coolant (ELC) - Change

Does the engine overheat frequently?

Is there foaming of the coolant?

Has oil entered the cooling system and contaminated the coolant?

Has fuel entered the cooling system and contaminated the coolant?

When the cooling system is cleaned, only clean water is needed when the ELC is drained and replaced.

Inspect the water pump and the water temperature regulator after the cooling system has been drained.

Is it necessary to replace the water pump, the water temperature regulator and the hoses?

Drain

500 Hourly Mini Hydraulic Excavator Maintenance

Belts - Inspect/Adjust/Replace Alternator Belt Adjustment

1. Remove the belt guard.

2. Loosen mounting bolts (1) and adjusting bolt (2).

3. Move the assembly in order to increase or decrease the belt tension.

4. Tighten adjusting bolt (2). Tighten mounting bolts (1).

5. Reinstall the belt guard.

If new drive belts are installed, check the drive belt tension again after 30 minutes of engine operation at the rated rpm.

Adjustment of the Fan Drive Belt

1. Remove the belt guard.

250 Hourly or 1 Yearly Mini Hydraulic Excavator Maintenance

Warning: All lead-acid batteries contain sulfuric acid which can burn the skin and clothing. Always wear a face shield and protective clothing when working on or near batteries.

Battery Electrolyte Level - Check

Check the condition of the electrolyte with the 245-5829 Coolant Battery Tester Refractometer.

Keep the batteries clean. Clean the battery case with one of the following cleaning solutions.

Electronics Grounding Stud - Inspect/Clean/Tighten

Engine Crankcase Breather - Clean

Engine Oil Sample - Obtain

Fuel System Primary Filter (Water Separator) Element - Replace

Fuel System Secondary Filter - Replace

Initial 250 Hours Mini Hydraulic Excavator Maintenance

Warning: Only qualified service personnel should perform this maintenance.

Ensure that the engine can not be started while this maintenance is being performed.

Hot engine components can cause burns. Allow additional time for the engine to cool before measuring/adjusting valve lash clearance.

Valve Lash - Inspect/Adjust

Note: For procedures on adjusting the valve lash and adjusting the valve bridge, consult your Caterpillar dealer for assistance.

The initial valve lash adjustment on new engines, rebuilt engines, or remanufactured engines is recommended at the first scheduled oil change.

The adjustment is necessary due to the initial wear of the valve train components and to the seating of the valve train components.

Valve Bridge Check

Check the valve bridge and adjust the valve bridge, if necessary. Perform the procedure for both valve bridges for each cylinder.

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX