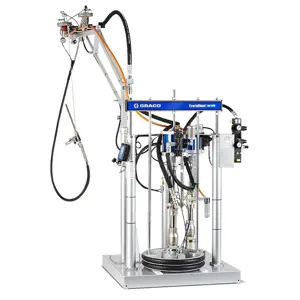

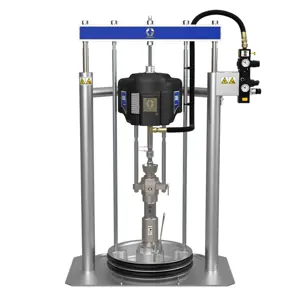

The Graco Electrostatic Air Spray Gun L60T12 is a high-performance asset designed for efficient and precise painting applications. This advanced spray gun utilizes electrostatic technology to enhance coating quality and reduce overspray, making it ideal for industrial use. Ensure optimal performance with regular maintenance and quality spare parts.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Graco Electrostatic Air Spray Gun L60T12

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Graco Electrostatic Air Spray Gun L60T12

Create an account to install this asset package.

Maintenance Plans for Graco Electrostatic Air Spray Gun Model L60T12

Integrate maintenance plans directly into your work orders in MaintainX.

2000 Hourly Alternator Bearing Replacement

Prepare the Gun for Service (Refer to page 48)

Remove the power supply/alternator assembly and disconnect the alternator (Refer to Power Supply Removal and Replacement, page 54)

Measure resistance between the two outer terminals of the 3-wire connector (PC); it should be 2.0–6.0 ohms

If resistance is outside the 2.0-6.0 ohms range, replace the alternator coil (15a)

Using a flat blade screwdriver, pry the clip (15h) off the housing (15d). Remove the cap (15f), using a thin blade or screwdriver

If necessary, rotate the fan (15e) so its blades clear the four bearing tabs (T) of the housing (15d)

Push the fan and coil assembly (15a) out the front of the housing (15d)

Hold the coil assembly (15a) on a workbench with the fan end facing up. Using a wide blade screwdriver, pry the fan (15e) off the shaft (S)

Remove the top bearing (15b2)

1 Daily Air Spray Gun Maintenance

Warning: Always follow the Pressure Relief Procedure whenever you are instructed to relieve the pressure.

Check gun resistance

Check hose resistance

Check electrical grounding

Check hoses, tubes, and couplings

Check equipment

Daily Care and Cleaning Checklist

Flush the gun

Clean the fluid and air line filters

Electrical Testing

Warning: Megohmmeter Part No. 241079 (AA) is not approved for use in a hazardous location. Follow the safety instructions to avoid fire, explosion, and electric shock.

Flush and dry the fluid passage.

For Model L40M14, L40T14, L40M15, and L40T15 guns only: Is the resistance between the metal pin (GP) and the air swivel (21) less than 100 ohms?

For all guns: Is the resistance between the electrode needle tip (3) and the air swivel (21) within the specified range for your gun type?

Remove the power supply (11). Follow the steps in Power Supply Removal and Replacement, page 54.

Remove the alternator (15) from the power supply. See Alternator Removal and Replacement, page 55.

Is the resistance from the power supply’s ground strips (EE) to the spring (11a) within the specified range for your gun type?

Remove the electrode (3). See Electrode Replacement, page 50.

Is the resistance between the contact (HH) and the electrode wire (GG) between 8–30 megohms?

Parts for Graco Electrostatic Air Spray Gun L60T12

Access the parts list for your equipment in MaintainX.

Bearing Kit

24N706

Resistance Meter

722886

Megohmmeter

241079

Probe

722860

Non-Silicone Grease

111265

Bearing Kit

24N706

Resistance Meter

722886

Megohmmeter

241079

Probe

722860

Non-Silicone Grease

111265

Bearing Kit

24N706

Resistance Meter

722886

Megohmmeter

241079

Probe

722860

Non-Silicone Grease

111265

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX