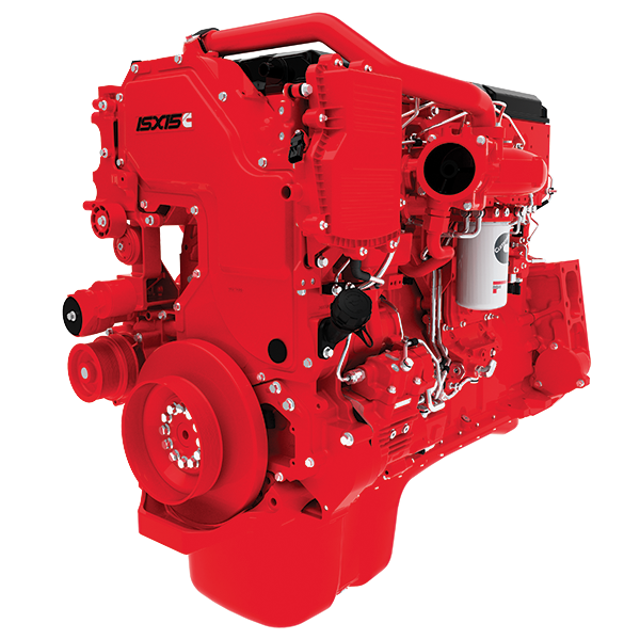

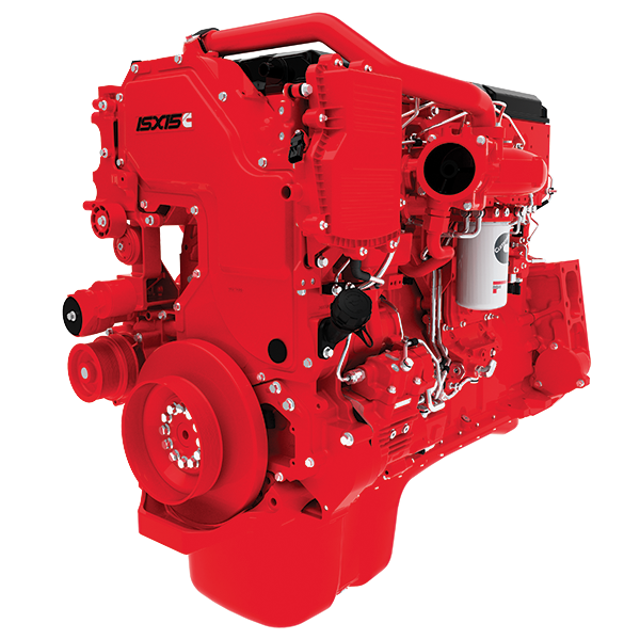

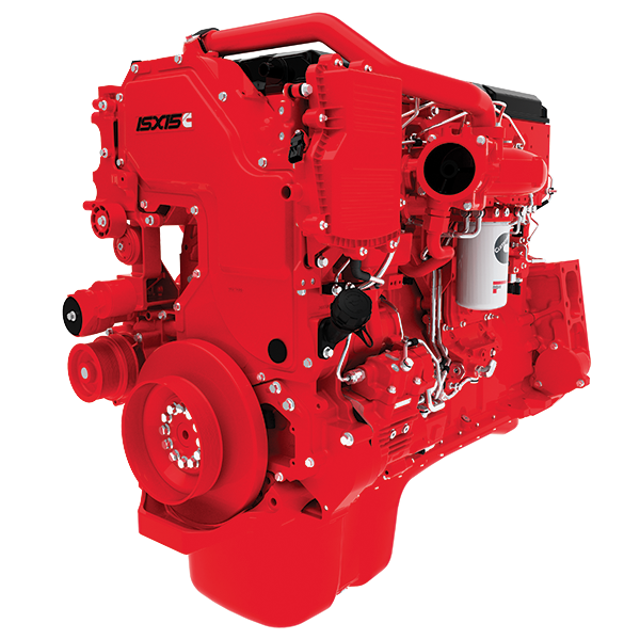

The Cummins Heavy Duty Engine ISX15 is a robust and reliable engine designed for commercial vehicles and heavy machinery. Known for its durability and efficiency, the ISX15 offers exceptional performance and low operating costs, making it a preferred choice in the industry.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Cummins Heavy Duty Engine ISX15

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Cummins Heavy Duty Engine ISX15

Create an account to install this asset package.

Maintenance Plans for Cummins Heavy Duty Engine Model ISX15

Integrate maintenance plans directly into your work orders in MaintainX.

60 Monthly / 10,000 Hourly Valve Adjustment

Valve Adjustment

Valves adjusted

Follow the procedures of valve adjustment

Contact your dealer for information about clearances of intake and exhaust

Sign off on the valve adjustment

1 Daily Heavy Duty Engine Check

Check the oil pressure indicators

Check temperature indicators

Check warning lights

Check other gauges

Check the oil pressure via the OEM instrument panel or gauge cluster

Check coolant temperatures via the OEM instrument panel or gauge cluster

Check DEF level via the OEM instrument panel or gauge cluster

Check other engine parameters via the OEM instrument panel or gauge cluster

Check the instrument panel for any alarm messages

24 Monthly / 6,750 Hourly Filters Replacement

Particulate Filter Replacement

Check Engine Lamp or Amber Warning Lamp flashing for 30 seconds after the key switch is set to ON

Enter the current mileage of the engine

Select the engine build date

Select the operating duty cycle

DEF Filter Replacement

Change the DEF Filter

Sign off on the filter replacement

6 Monthly / 1,000 Heavy Duty Engine Maintenance

Caution

Never crack a high pressure fuel line with the engine running. With the engine stopped, relieve pressure only at the fuel pump inlet line fitting on the side of the rail.

When changing the engine mounted fuel filter, never pre-fill by pouring fuel in the center hole (clean side). Recommended procedure is to install filter dry and cycle the key switch on 3–4 times and allow the priming pump to fill the filter.

If you have to pre-fill the filter, use the smaller outside holes (dirty side) and let the fuel flow through the filter media to provide clean, filtered fuel to the clean side.

Synthetic or Semi-Synthetic oils may be beneficial for extreme arctic or extreme heat conditions but DO NOT EXTEND Oil Drain Intervals with synthetic or semi-synthetic oils.

10W-30 oils meeting Cummins specifications may be used in these engines.

Oil and Filter Replacement

- Change Oil and Filter.

Fuel Filter Replacement

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX