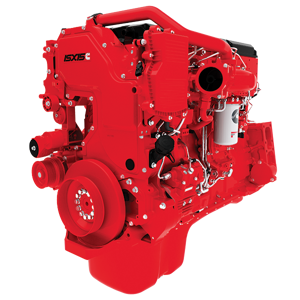

The Cummins Diesel Generator C200D6 is a robust and reliable power solution designed for industrial applications. Known for its efficiency and durability, this generator model ensures consistent performance and minimal downtime, making it an ideal choice for various operational needs.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Cummins Diesel Generators C200D6

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Cummins Diesel Generators C200D6

Create an account to install this asset package.

Maintenance Plans for Cummins Diesel Generators Model C200D6

Integrate maintenance plans directly into your work orders in MaintainX.

Filter Replacement

Warning: Ensure the unit is powered off before starting the procedure.

Side access panel removed

Filter retainer clip removed

Old filters removed

New filters installed

For larger units with 2 fans, use the factory-supplied filter hook.

Filter hook used to slide filters within reach for removal

Sign off on the filter replacement

Airside Equipment Maintenance

Inspection and maintenance should be performed at regular intervals and should include the following:

Complete cleaning of cabinet, fan wheel, cooling coil, condensate pan and drain, heating coils, and return-air grille (if present).

Inspection of panels and sealing of unit against air leakage.

Adjustment of fan motor, belt, bearings, and wheels.

Cleaning or replacement of filters.

Testing for cooling/heating system leaks.

Checking of all electrical connections.

Most unit service can be performed by removing one or both of the unit’s side panels. Coil cleaning or removal or insulation cleaning may require removal of a rear, top, or bottom panel, depending on the unit’s orientation. When service is completed, replace unit panels.

Panels — Panels are fastened to unit frame with sheet metal screws. Fan and coil compartment must be sealed tightly after service to prevent air from bypassing the cooling coil.

Parts for Cummins Diesel Generators C200D6

Access the parts list for your equipment in MaintainX.

NOZZLE

C8

DISTRIBUTOR

1116

NOZZLE

C15

DISTRIBUTOR

1657

TXV

TDEX4

NOZZLE

C8

DISTRIBUTOR

1116

NOZZLE

C15

DISTRIBUTOR

1657

TXV

TDEX4

NOZZLE

C8

DISTRIBUTOR

1116

NOZZLE

C15

DISTRIBUTOR

1657

TXV

TDEX4

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX