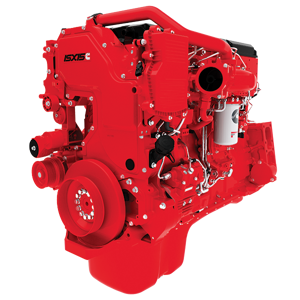

The Cummins Natural Gas Generator C100N6 is a reliable and efficient power solution designed for various industrial applications. With its robust engineering and advanced technology, this generator ensures optimal performance and longevity, making it an ideal choice for businesses seeking dependable energy sources.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Cummins Natural Gas Generators C100N6

Create an account to install this asset package.

Maintenance Plans for Cummins Natural Gas Generators Model C100N6

Integrate maintenance plans directly into your work orders in MaintainX.

Generator Maintenance

Press the Off switch from the display and then press the E-Stop button to shut down the engine.

Ventilate the generator set before disconnecting any leads.

Turn off and disconnect the heater (where fitted) from the AC source before disconnecting the battery cables.

Turn off and disconnect the battery charger (where fitted) from the AC source before disconnecting the battery cables.

Turn off the fuel supply to the engine.

Disconnect the battery. Disconnect the negative (-) cable first, using an insulated wrench.

Place warning notices at each of the above locations that state, 'Maintenance in Progress - Immobilized for Safe Working.'

Sign off on the generator maintenance

Heavy Duty Air Cleaner Element Replacement

CAUTION: Holes, loose-end seals, dented sealing surfaces, corrosion of pipes, and other forms of damage render the air cleaner inoperative and require immediate element replacement or engine damage can occur.

NOTICE: Cummins Inc. does not recommend cleaning paper-type air cleaner elements.

Wipe dirt from the cover and the upper portion of the air cleaner

Lift the latch (3) and turn the end cover (4) counterclockwise

Pull the end cover (4) away from the housing (1)

Remove the air filter element (2) from the housing (1)

Dispose of the dirty element in accordance with local environmental agency requirements

Ensure that no debris enters the filter element or connection point on the air cleaner housing

Insert the air filter element (2) into the housing (1)

12 Monthly or 250 Hourly Natural Gas Generators Maintenance

Air cleaner replaced

Coolant lines and radiator hoses checked for leaks, wear and cracks

Radiator core cleaned

Water pump checked for leaks

Coolant heater checked for power and leaks

CCV heater checked for leaks

Alternator heater checked for general condition and wiring connections

Battery heater checked for general condition and wiring connections

Engine oil heater checked for general condition and wiring connections

Spark Plugs Maintenance

NOTICE: Make sure service personnel are qualified to perform electrical and mechanical service. The generator set has six spark plugs, all accessible from the top of the engine. The spark plugs must be in good condition for proper engine starting and performance. A spark plug that fouls frequently or has heavy soot deposits indicates the need for engine service.

Set the generator set control to the Off position before checking the spark plugs.

To prevent cross-threading a spark plug, always thread it in by hand until it seats. Torque the spark plug to 38 Nm (28 Ib-ft).

Return the generator set control to the desired setting when finished performing maintenance.

Sign off on the spark plugs maintenance

Oil Maintenance

WARNING: Hot Surfaces. Contact with hot surfaces can cause severe burns. Wear appropriate PPE when working on hot equipment and avoid physical contact with hot surfaces.

WARNING: Hot Engines. Contact with hot engines can cause severe burns. Ensure that the generator set engine has cooled down before adding or draining the oil.

NOTICE: Too much oil can cause high oil consumption. Too little oil can cause severe engine damage. Keep the oil level between the High and Low marks on the dipstick.

Is the oil level sufficient?

Adding Oil: If the oil level is found to be insufficient, oil must be added.

Is the oil fill cap area clean?

Enter the amount of oil added

Is the engine oil level correct after adding oil?

Clean up and dispose of any oil in accordance with local/state regulations.

Parts for Cummins Natural Gas Generators C100N6

Access the parts list for your equipment in MaintainX.

Guide Pins

3164977

Barring Tool

3824591

EControls GCP E-Com USB Interface Cable

A047A982

Electronic Cleaner

3824510

Wear Sleeve Installation Tool

3824078

Guide Pins

3164977

Barring Tool

3824591

EControls GCP E-Com USB Interface Cable

A047A982

Electronic Cleaner

3824510

Wear Sleeve Installation Tool

3824078

Guide Pins

3164977

Barring Tool

3824591

EControls GCP E-Com USB Interface Cable

A047A982

Electronic Cleaner

3824510

Wear Sleeve Installation Tool

3824078

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX