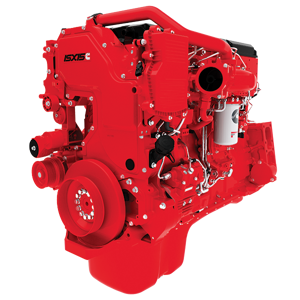

The Cummins Diesel Generator C500D6 is a robust and reliable power solution designed for industrial applications. Known for its durability and efficiency, this generator model provides dependable performance and is ideal for various operational needs, ensuring continuous power supply in demanding environments.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Cummins Diesel Generators C500D6

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Cummins Diesel Generators C500D6

Create an account to install this asset package.

Maintenance Plans for Cummins Diesel Generators Model C500D6

Integrate maintenance plans directly into your work orders in MaintainX.

VICTAULIC COUPLING INSTALLATION

Warning: Ensure the outside surface of the pipe is smooth and free from indentations, projections, and roll marks

Is the pipe surface clean from oil, grease, loose paint, and dirt?

Apply a thin coat of Victaulic lubricant or silicone lubricant to the gasket sealing lips and exterior

Is the gasket positioned correctly over the pipe end?

Are the two pipe ends aligned and brought together?

Is the gasket centered between the groove in each pipe end?

Are the housings installed over the gasket correctly?

Ensure the housings’ keys engage the grooves completely on both pipe ends

Are the bolts installed and a nut finger-tight onto each bolt?

The System Maintenance

FILLING THE SYSTEM

The entire piping system filled with water

Pressure at the top of the system (should be at least 4 psig [28 kPa])

Pressure at all points in the system high enough to prevent flashing in the piping or cavitation in the pump

The best location to install the fill connection is close to the expansion tank. An air vent should be installed close by to help eliminate air that enters during the fill procedure.

Temporary bypass piping and cleaning/flushing equipment removed

All drain plugs are installed

Blow-down valve opened to flush the strainer

Normally, a closed system needs to be filled only once. The actual filling process is generally a fairly simple procedure. All air should be purged or vented from the system. Thorough venting at the high points and circulation at room temperature for several hours is recommended.

Mounting Unit Maintenance

Ensure the unit is in the proper location and secured to the supporting structure.

Is the unit level to within 1/8 in. (.32 mm) per foot for proper oil return to compressor?

Check Compressor Mounting

Are units with single compressors held down with 4 bolts through rubber grommets?

Are units with tandem compressors held down with 6 bolts per pair through grommets?

Verify mounting bolt torque 7 to 10 ft-lb (9.5 to 13.6 N•m)

For 30RAP100-150 units, remove RED bolts from compressor mounting rail and RED shipping braces.

Connect Cooler Fluid and Drain Piping

Is the strainer in place?

The compression tank Maintenance

Warning: This maintenance check requires trained personnel with PPE!

Does the compression tank provide net positive suction head required (NPSHR) for the pump to operate satisfactorily?

Enter the system pressure

Does the compression tank accommodate expansion/contraction of water due to temperature changes?

Does the compression tank act as a pressure reference for the pump?

Sign off on the compression tank maintenance

Air Separation Maintenance

Warning: This procedure requires trained personnel with PPE!

Free air in the system causing noise or reducing terminal output?

If free air is causing issues, report to the maintenance team and stop the procedure

Choose the location of air separator installation

Enter the water temperature at the point of air separator installation

Enter the water pressure at the point of air separator installation

Air separator installed at the point of highest water temperature and lowest pressure?

If not, specify the reason

Enter the water velocity

Parts for Cummins Diesel Generators C500D6

Access the parts list for your equipment in MaintainX.

Dual Leaving Water Thermistor Wel

10HB50106801

Dual Leaving Water Thermistor Wel

10HB50106802

Dual Leaving Water Thermistor Wel

10HB50106801

Dual Leaving Water Thermistor Wel

10HB50106802

Dual Leaving Water Thermistor Wel

10HB50106801

Dual Leaving Water Thermistor Wel

10HB50106802

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX