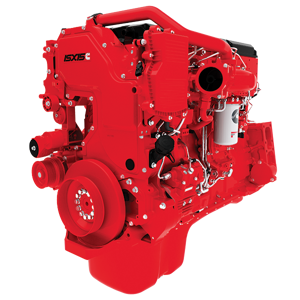

The Cummins Diesel Generator C50D6 is a robust and reliable power solution designed for industrial applications. Known for its durability and efficiency, this generator model ensures optimal performance and minimal downtime, making it an ideal choice for various operational needs.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Cummins Diesel Generators C50D6

Create an account to install this asset package.

Maintenance Plans for Cummins Diesel Generators Model C50D6

Integrate maintenance plans directly into your work orders in MaintainX.

1 Daily or 24 Hourly Diesel Generators Maintenance

Check air cleaner restriction indicator (where fitted): If the service indicator shows red, replace air cleaner elements and reset the air cleaner service indicator.

Check air intake system for leaks: Visually inspect the air intake system for signs of wear or damage. Check audibly when the generator set is running. Replace worn or damaged components.

Check operation of operator panel: Check display (the system will perform a control panel test on initial activation). Replace component if not functioning properly.

Check coolant level of radiator(s): If low, top up to coolant system specifications level, with Cummins recommended coolant mix.

Check cooling fan blades: Visually inspect the fan blades through the guarding for signs of wear or damage.

Check drive belt, condition and tension: Visually check belt for evidence of wear or slippage.

Check coolant lines and radiator hoses for leaks, wear, and cracks: Visually check for leaks, worn or damaged hoses.

Check radiator air flow: Visually inspect the radiator through the guarding for blockage, build-up of debris, signs of wear or damage.

Verify that the coolant heater has power and is running (where fitted). Check for evidence of leaks. Remove any corrosion from fittings.

12 Monthly or 200 Hourly Diesel Generators Maintenance

Replace engine oil and filters. Refer to the Engine Oil section for the procedure.

Clean radiator core.

Check charge air cooler for damage and debris (where fitted).

Check water pump for leaks.

Check weep holes for evidence of leaks. Replace if leaking.

Engine oil and filters replaced?

Radiator core cleaned?

Charge air cooler checked for damage and debris?

Water pump checked for leaks?

1 Weekly or 50 Hourly Diesel Generators Maintenance

Replace engine oil and filters. Refer to the Engine Oil section for the procedure.

Before changing the oil, the generator set should be operated until the water temperature is approximately 60 C (140 °F).

Make sure the generator set is shut down and disabled.

Press the generator set's 'O' (Off) button to stop the generator set. Allow the generator set to thoroughly cool to the touch.

If applicable, turn off and disconnect the battery charger from the AC source before disconnecting the battery cables.

Disconnect the negative (-) cable from the battery and secure it from contacting the battery terminals to prevent accidental starting.

Drain the oil. Place the end of the drain hose into an appropriate container.

Remove the oil filter, and clean the filter mounting surface on the engine block. Remove the old gasket if it remains.

Make sure the gasket is in place on the new filter and apply a thin film of clean oil to the gasket.

Test the Insulation Resistance of Windings

NOTICE: The alternator must not be put into service until the minimum insulation resistance is achieved.

Inspect the windings for mechanical damage or discoloration from overheating.

Clean the insulation if there is hygroscopic dust and dirt contamination.

Disconnect the neutral to earth conductor (if equipped).

Connect together the three leads of all phase windings (if possible).

Apply the test voltage from the table between any phase lead and earth.

Measure the winding insulation resistance after 1 minute (IR1min).

Disconnect all control wiring and customer load leads from the alternator winding connections before conducting these tests.

Discharge the test voltage with an earth rod for 5 minutes.

Alternator Replacement

Remove enclosure components

Roof, side doors, and end cap removed

Terminal box cover and dome, and the covers attached to the dome on either side of the alternator facing the rear of the engine removed

Cover panels (2 per side) from the terminal boxes (8 bolts on each side) removed

All wires are labelled, marked or photographed so that they can be reconnected to the same points

All wires in the circuit breaker box that are connected to the alternator (load, neutral and ground) disconnected

Wires pushed through the terminal box to disconnect the terminal box from the alternator

Connectors J17, J18 and J22 from the control board disconnected

Alternator air inlet grill and drip cover from the terminal box (3 bolts per side) removed

Parts for Cummins Diesel Generators C50D6

Access the parts list for your equipment in MaintainX.

Lifting Kit

A048W006

Electronic Cleaner

3824510

Lifting Kit

A048W006

Electronic Cleaner

3824510

Lifting Kit

A048W006

Electronic Cleaner

3824510

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX