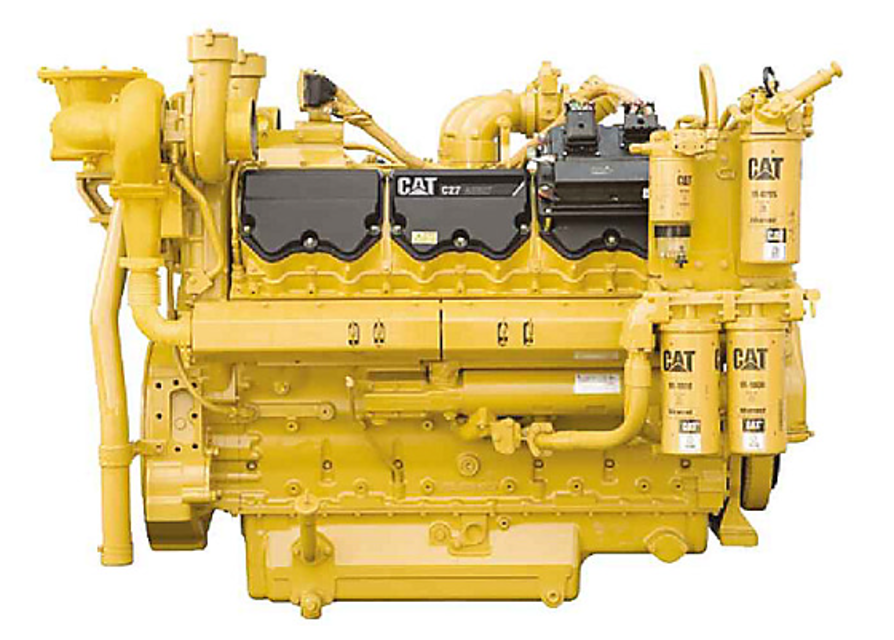

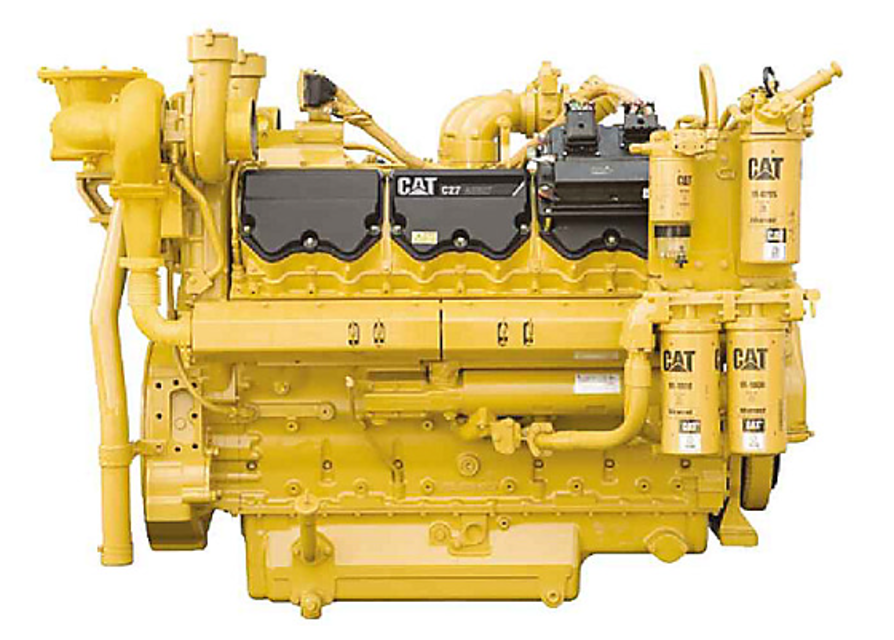

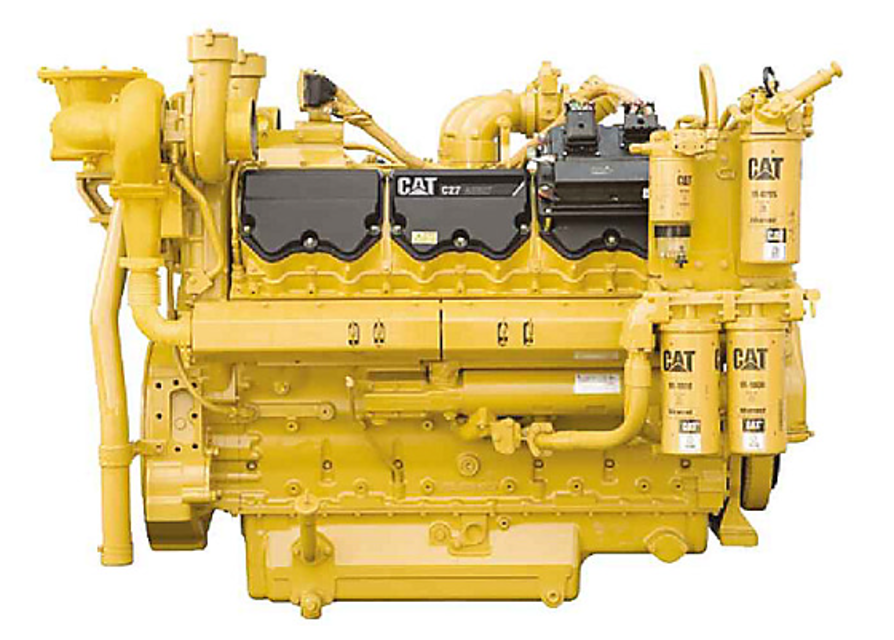

The Caterpillar Generator C27 is a robust and reliable power generation solution designed for industrial applications. Known for its durability and efficiency, this generator model provides dependable performance in various environments, making it an ideal choice for businesses requiring consistent power supply.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Caterpillar Generator С27

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Caterpillar Generator С27

Create an account to install this asset package.

Maintenance Plans for Caterpillar Generator Model С27

Integrate maintenance plans directly into your work orders in MaintainX.

Overhaul Generator Maintenance

Generator Bearing - Inspect/Replace

Inspect

1. Remove the bearing bracket. Inspect the following items: bracket bore, bearing outer race, and rolling elements. On standby power units, the bearing must be inspected and the grease must be replaced at three year intervals.

The sleeve in the bearing bracket should be inspected for out of roundness, excessive wear, and a bracket step that is less than 0.0762 mm (0.0030 inch). If there is no sleeve in the bearing bracket, inspect the bore of the bearing bracket. The bearing should be inspected for damage to the outer race, severe fretting, and smoothness of operation.

When possible, the bearing elements should be inspected. Some double shielded ball bearings prevent visual inspection of the elements of the bearing. Other double shielded ball bearings have a retaining ring. This retaining ring can be removed in order to allow access for a visual inspection of the elements of the bearing.

On two-bearing generators, the front bearing can only be removed after the drive coupling is removed. Refer to the Systems Operation Testing and Adjusting Disassembly and Assembly, “Coupling - Remove” for the generator for instructions for removing the drive coupling.

Replace

1. All ball bearings should be cleaned. The cavity in the bracket should be repacked with 2S-3230 Grease. Pack the ball bearings (one-third to one-half of the volume of the cavity).

2. Use an induction heater to heat the ball bearings to 107 °C (224.6 °F) for ten minutes in order to install either of the following bearings: ball bearings that are new and ball bearings that have been inspected. Mount the bearings on the shaft. To reinstall the hub, heat the hub to 400 °C (752.0 °F) for three hours. Mount the hub to the shaft.

3 Yearly Generator Maintenance

WARNING: Batteries give off combustible gases which can explode. A spark can cause the combustible gases to ignite. This can result in severe personal injury or death.

Ensure proper ventilation for batteries that are in an enclosure. Follow the proper procedures in order to help prevent electrical arcs and/or sparks near batteries. Do not smoke when batteries are serviced.

Turn the key start switch to the OFF position. Remove the key and all electrical loads.

Turn OFF the battery charger. Disconnect the charger.

The NEGATIVE “-” cable connects the NEGATIVE “-” battery terminal to the ground plane. Disconnect the cable from the NEGATIVE “-” battery terminal.

The POSITIVE “+” cable connects the POSITIVE “+” battery terminal to the starting motor. Disconnect the cable from the POSITIVE “+” battery terminal.

Remove the used battery.

Install the new battery.

Connect the cable from the starting motor to the POSITIVE “+” battery terminal.

250 Hourly Generator Maintenance

Battery Electrolyte Level - Check

When the engine is not run for long periods of time or when the engine is run for short periods, the batteries may not fully recharge. Ensure a full charge in order to help prevent the battery from freezing.

WARNING: All lead-acid batteries contain sulfuric acid which can burn the skin and clothing. Always wear a face shield and protective clothing when working on or near batteries.

1. Remove the filler caps. Maintain the electrolyte level to the “FULL” mark on the battery.

If the addition of water is necessary, use distilled water. If distilled water is not available use clean water that is low in minerals. Do not use artificially softened water.

2. Check the condition of the electrolyte with the 245-5829 Coolant Battery Tester Refractometer.

3. Keep the batteries clean.

Clean the battery case with one of the following cleaning solutions:

• A mixture of 0.1 kg (0.2 lb) of baking soda and 1 L (1 qt) of clean water

1 Daily Generator Maintenance

Cooling System Coolant Level - Check

Check the coolant level when the engine is stopped and cool.

Remove the cooling system filler cap slowly in order to relieve pressure.

Maintain the coolant level within 13 mm (0.5 inch) of the bottom of the filler pipe.

Clean the cooling system filler cap and check the condition of the filler cap gaskets.

Inspect the cooling system for leaks.

Engine Oil Level - Check

Maintain the oil level between “ADD” mark (Y) and “FULL” mark (X) on the oil level gauge.

Remove the oil filler cap and add oil, if necessary.

2000 Hourly Generator Maintenance

Engine Mounts - Check

Misalignment of the engine and the driven equipment

Excessive vibration

Improper mounting

Loose bolts

Deterioration of the isolators

Fuel Injector - Inspect/Adjust

Camshafts correctly timed with the crankshaft

Lash for the fuel injector adjusted

Parts for Caterpillar Generator С27

Access the parts list for your equipment in MaintainX.

Ball Bearing 326 BC 279.9817 ± 0.0178 mm (11.0229 ± .0007 inch) OD 129.9870 ± 0.0127 mm (5.1176 ± .0005 inch) ID

154-3032

Ball Bearing 322 BC 239.9843 ± 0.0152 mm (9.4482 ± .0006 inch) OD 109.9896 ± 0.0102 mm (4.3303 ± .0004 inch) ID

108-1761

Bearing 315 BB 159.9870 ± 0.0127 mm (6.2987 ± .0005 inch) OD 74.9935 ± 0.0076 mm (2.9525 ± .0003 inch) ID

243-5220

Roller Bearing

139-0349

Bearing 307 BC 79.9935 ± 0.0063 mm (3.14935 ± .00025 inch) OD 34.9923 ± 0.0063 mm (1.37765 ± .00025 inch) ID

262-5921

Ball Bearing 326 BC 279.9817 ± 0.0178 mm (11.0229 ± .0007 inch) OD 129.9870 ± 0.0127 mm (5.1176 ± .0005 inch) ID

154-3032

Ball Bearing 322 BC 239.9843 ± 0.0152 mm (9.4482 ± .0006 inch) OD 109.9896 ± 0.0102 mm (4.3303 ± .0004 inch) ID

108-1761

Bearing 315 BB 159.9870 ± 0.0127 mm (6.2987 ± .0005 inch) OD 74.9935 ± 0.0076 mm (2.9525 ± .0003 inch) ID

243-5220

Roller Bearing

139-0349

Bearing 307 BC 79.9935 ± 0.0063 mm (3.14935 ± .00025 inch) OD 34.9923 ± 0.0063 mm (1.37765 ± .00025 inch) ID

262-5921

Ball Bearing 326 BC 279.9817 ± 0.0178 mm (11.0229 ± .0007 inch) OD 129.9870 ± 0.0127 mm (5.1176 ± .0005 inch) ID

154-3032

Ball Bearing 322 BC 239.9843 ± 0.0152 mm (9.4482 ± .0006 inch) OD 109.9896 ± 0.0102 mm (4.3303 ± .0004 inch) ID

108-1761

Bearing 315 BB 159.9870 ± 0.0127 mm (6.2987 ± .0005 inch) OD 74.9935 ± 0.0076 mm (2.9525 ± .0003 inch) ID

243-5220

Roller Bearing

139-0349

Bearing 307 BC 79.9935 ± 0.0063 mm (3.14935 ± .00025 inch) OD 34.9923 ± 0.0063 mm (1.37765 ± .00025 inch) ID

262-5921

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX