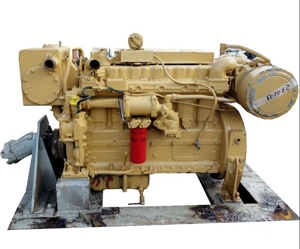

The CAT Skid Steer Loader 299D is a versatile and powerful machine designed for various construction and landscaping tasks. Known for its robust performance and reliability, this loader excels in tight spaces, making it an essential asset for contractors and operators alike.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

CAT Skid Steer Loader 299D

Create an account to install this asset package.

Maintenance Plans for CAT Skid Steer Loader Model 299D

Integrate maintenance plans directly into your work orders in MaintainX.

Radiator Tilting

Note: All models except for 226D, 232D, 239D, and 249D.

Open the engine access door. Refer to Operation and Maintenance Manual, “Access Doors and Covers”.

The release latch for the guard is located on the rear of the radiator. Pull the rubber T-handle down to release the guard. Tilt the guard upward.

To raise the radiator, remove the two bolts.

Raise the radiator. As the radiator raises, the latch will move (1).

Raise the radiator until the latch moves over the catch pin (2).

To lower the radiator downward, push up on the radiator. Move the latch to unlatch the lock. Lower the radiator.

Install the two bolts to secure the radiator.

To lower the radiator guard, move the support rod to the storage position and lower the guard.

1500 Hourly Skid Steer Loader Maintenance

Engine Crankcase Breather - Replace

Note: Only applies to engines with aftertreatment.

Open the engine access door. Refer to Operation and Maintenance Manual, “Access Doors and Covers”.

Tilt the radiator upward. Refer to Operation and Maintenance Manual, “Radiator Tilting”.

The breather is located in the engine compartment on the right-hand side of engine. There is cap on the breather and a replaceable element inside.

Note: This service may be performed without removing the housing from the engine.

Remove the breather cap and remove the filter element.

Note: The C2.2 and C3.3B are equipped with cap on bottom portion of the canister. Use a wrench to remove the breather cap. The C3.8 is equipped with cap on top of canister, remove cap by applying downward pressure on the cap while turning.

Clean the housing and the cap for the breather.

3000 Hourly Skid Steer Loader Maintenance

Diesel Exhaust Fluid Filter - Replace

Ensure that the engine is stopped before any servicing or repair is performed.

The DEF filter is located on the left side of the machine under the cab. Tilt the cab upward.

Did you remove the black plastic cover and then diesel exhaust fluid (DEF) filter assembly?

Did you install new DEF filter and replace DEF filter cap?

Tilt the cab downward.

Diesel Fuel System Cleaner - Add

Add Cat Diesel Fuel System Cleaner every 3000 hours of engine operation.

Pour 0.95L (32 oz.) of the cleaner into a full tank of diesel fuel and operate the machine normally.

6000 Hourly Skid Steer Loader Maintenance

Cooling System Coolant Extender (ELC) - Add

When a Cat Extended Life Coolant is used, an extender must be added to the cooling system periodically.

Open the engine access door and raise the radiator guard. Refer to Operation and Maintenance Manual, “Access Doors and Covers”.

Is the radiator cap located on the left side of the radiator (C3.3B and C3.8 engines) or the right side of the radiator (C2.2 engine)?

Slowly loosen the radiator cap in order to relieve system pressure. Remove the radiator cap.

Is it necessary to drain enough coolant from the radiator in order to allow the addition of the coolant additive?

Add 0.17 L (0.18 qt) of cooling system additive.

Inspect the radiator cap and the gasket. If the cap or the gasket is damaged, replace the cap. Install the radiator cap.

Check the coolant level in the sight gauge on the radiator. Maintain the coolant level to the top of the sight gauge with the radiator in the LOWERED position.

2000 Hourly Skid Steer Loader Maintenance

Cooling System Coolant Sample (Level 2) - Obtain

NOTICE: Always use a designated pump for oil sampling, and use a separate designated pump for coolant sampling.

Warning: Pressurized system: Hot coolant can cause serious burn. To open cap, stop engine, wait until radiator is cool. Then loosen cap slowly to relieve the pressure.

Sample of the coolant obtained from the radiator?

Note: Do not take the sample from the Coolant Overflow Reservoir.

Obtain the sample of the coolant as close as possible to the recommended sampling interval.

Submit the sample for Level 2 analysis.

Hydraulic System Oil - Change

Hydraulic oil tank cap removed?

Parts for CAT Skid Steer Loader 299D

Access the parts list for your equipment in MaintainX.

Refractometer

360-0774

Refractometer

360-0774

Refractometer

360-0774

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX