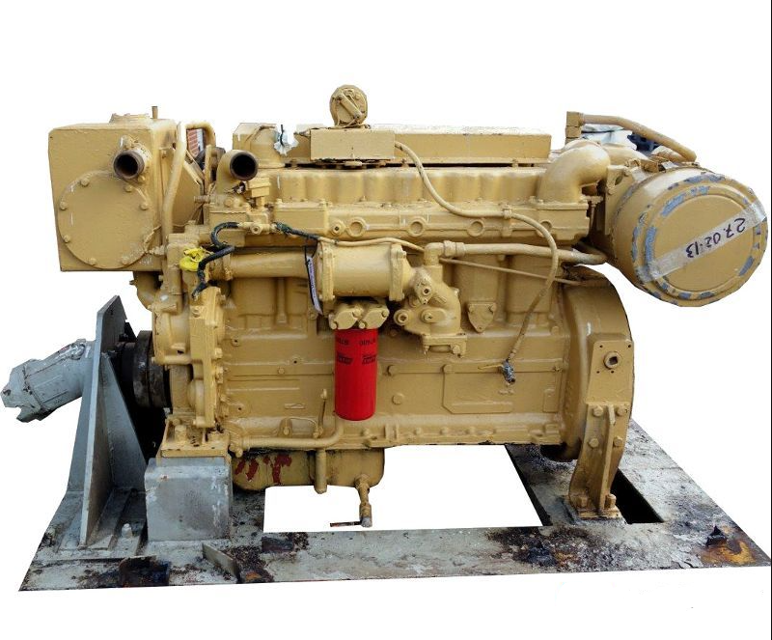

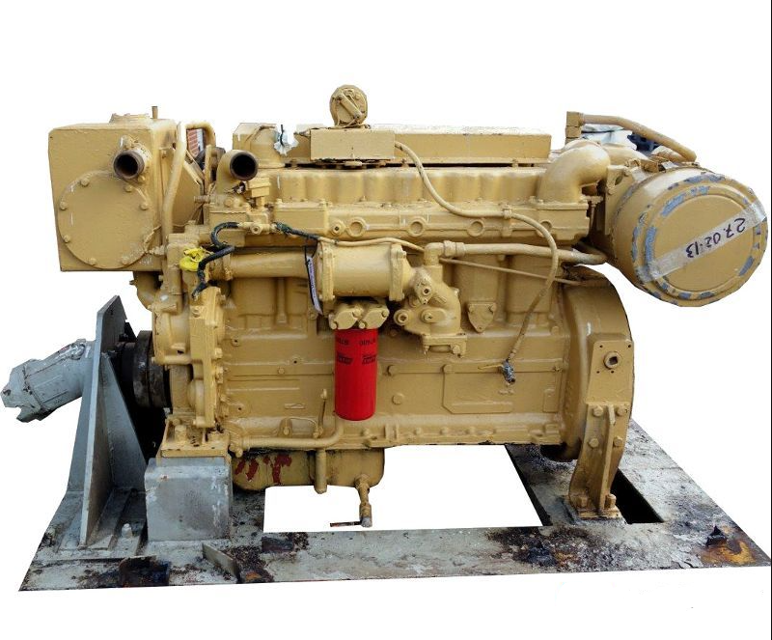

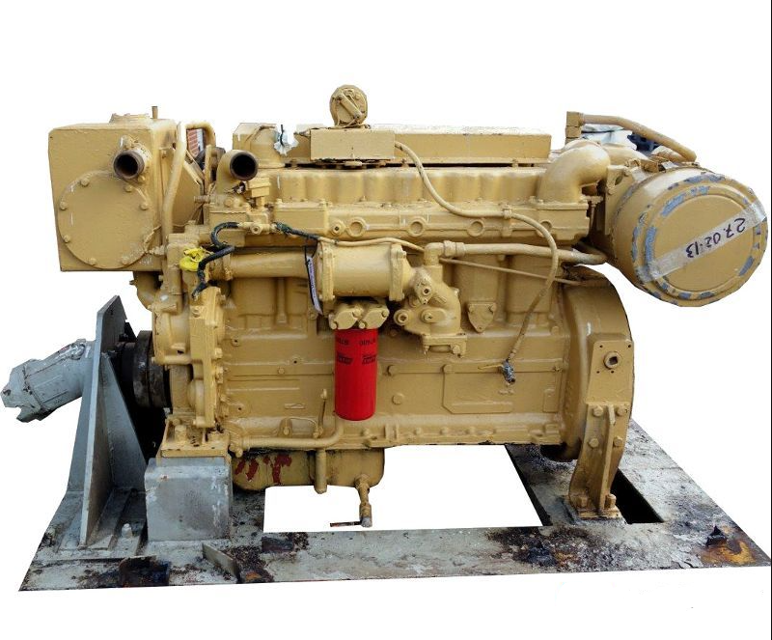

The CAT Bulldozer D6 is a robust and versatile piece of heavy equipment designed for earthmoving and construction tasks. Known for its durability and efficiency, the D6 model excels in various applications, making it a reliable choice for contractors and operators in the industry.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for CAT Bulldozer D6

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

CAT Bulldozer D6

Create an account to install this asset package.

Maintenance Plans for CAT Bulldozer Model D6

Integrate maintenance plans directly into your work orders in MaintainX.

When Required Engine Maintenance

Cooling System-Cleaning

Check coolant level ONLY when engine is stopped and radiator cap is cool enough to touch with your hand.

Remove filler cap slowly to relieve pressure.

Remove radiator drain plug.

Remove the engine block drain plug.

Install drain plugs. Fill system with a commercially available cleaning solution or 1 kilogram (2 lb.) Sodium Bisulfate (NaHSO.) per 40 liters (10 U.S. gallons) water.

Start and run for 1/2 hour. Stop engine and drain cleaning solution.

Flush system with clean water until draining water is clean. Do not run engine while flushing.

Install all drain plugs. Fill system with neutralizing solution or 250 grams (1/2 lb.) Sodium Carbonate Crystals (Na,CO.H2O) per 40 liters (10 U.S. gallons) water.

1000 Hourly Engine Maintenance

Woodward PSG Governor

Lubricate 2 fittings

Synchronizing Motor

Fill oil cup

Shutoff Controls

The shutoff controls must be checked periodically so that they will function properly, when required. To prevent damage to the engine while making the required test, only authorized personnel should perform the checks. Contact your Caterpillar dealer.

Tachometer Drive

Lubricate 1 fitting

Sign off on the 1000 Hourly Engine Maintenance

125 Hourly Engine Maintenance

Clutch Control Lever

Lubricate 2 fittings; 1 fitting on each side of the clutch housing.

Clutch Pilot Bearing

Lubricate 1 fitting at the end of shaft.

Clutch Main Shaft Bearing

Lubricate 1 fitting on top-rear of housing.;

500 Hourly Engine Maintenance

Engine Crankcase (N. A. Engine)-Change Oil and filter

Change oil, filter and clean breather. See Item (13) for details.

Fan Bearing

Lubricate 1 fitting.

Fuel System

The primary fuel filter should be cleaned and the final fuel filter element replaced every 500 service hours of operation or when the fuel gauge registers "OUT" with the engine running.

Refer to "Fuel System" in "When Required" section for procedure to change the fuel filters.

Sign off on the 500 Hourly Engine Maintenance

50 Hourly Engine Maintenance

Dust Collector Cup-Clean

1. Remove the retaining wing nut from the top of the dust collector cup.

2. Remove and clean the dust collector cup.

3. Install the dust collector cup.

Batteries-Check Electrolyte Level

WARNING: Do not smoke when observing battery electrolyte level. Batteries give off fumes that can explode.

WARNING: Electrolyte is an acid and can cause personal injury if it contacts skin or eyes.

1. Clean the tops of the batteries. Keep the terminals clean and covered with a light coat of grease.

2. Remove all fill caps. Observe the electrolyte level.

Parts for CAT Bulldozer D6

Access the parts list for your equipment in MaintainX.

Fuel

SEHS7067

Engine Coolant

SEBD0518

Fuel

SEHS7067

Engine Coolant

SEBD0518

Fuel

SEHS7067

Engine Coolant

SEBD0518

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX