Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

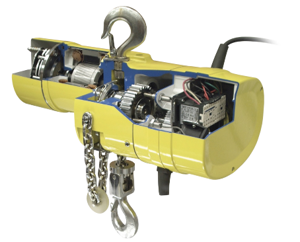

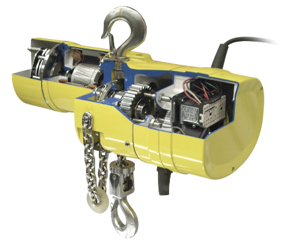

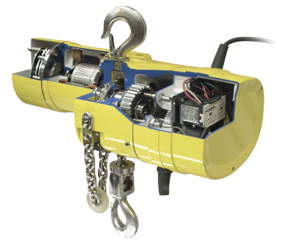

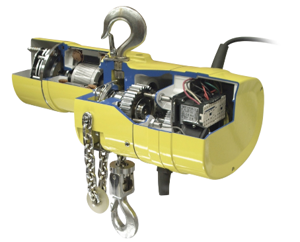

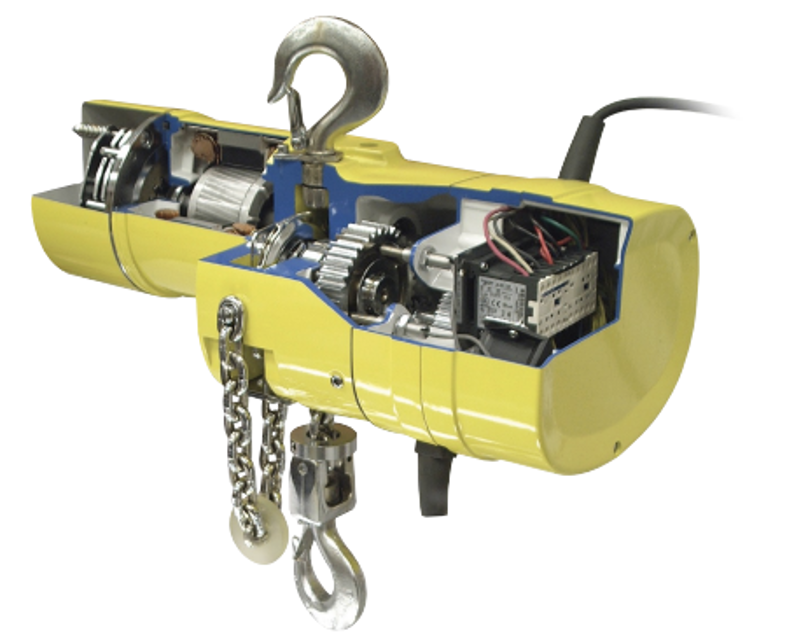

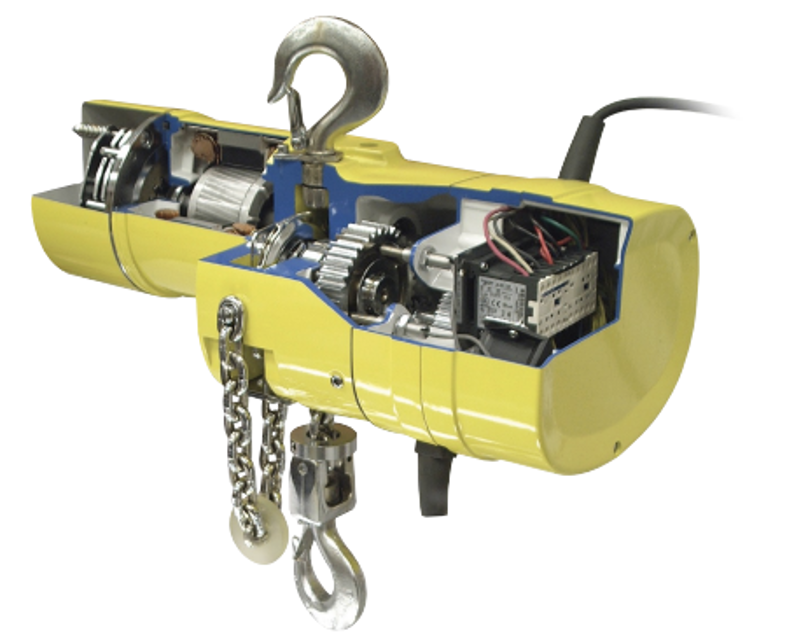

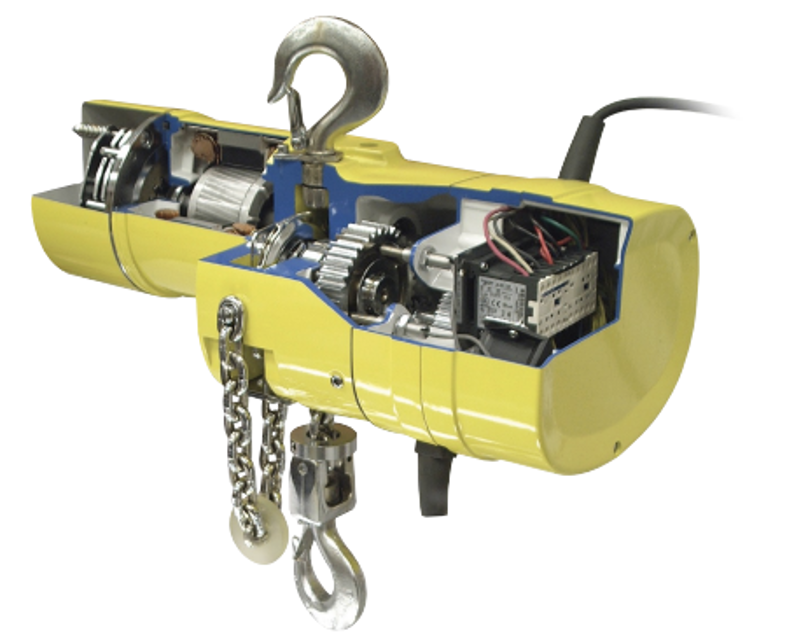

Manual for Budgit Portable Electric Hoist 1/4-Ton

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Budgit Portable Electric Hoist 1/4-Ton

Create an account to install this asset package.

Maintenance Plans for Budgit Portable Electric Hoist Model 1/4-Ton

Integrate maintenance plans directly into your work orders in MaintainX.

1 Weekly Coil Chain Lubrication

Coil Chain

Coil chain cleaned with oil solvent

Coil chain lubricated with oil

Lubricant coated on wear surfaces between links

Sign off on the coil chain lubrication

1 Monthly Upper Suspension Inspection

THIRTY-DAY INSPECTION.

Hoist may be left suspended.

c. Inspect Upper Suspension.

(1) On hook suspended models, check for bent or distorted hook.

If hook is opened beyond the dimension given in figure 5-6, it must be replaced.

Also check to see that hook pivots.

Lubricate if necessary.

(2) On lug suspended models, check condition of suspension lug.

Replace lug if damaged or cracked.

5000 Hourly / 5 Yearly Sprocket, Intemediate Gears Inspecton

INSPECTION: 5000 HOURS “ON” TIME OR 5 YEARS ELAPSED TIME.

Hoist must be removed from overhead suspension.

d. Inspect Sprocket and Intermediate Gears.

(1) On 1 through 3 ton hoists, check condition of gear teeth on intermediate gear and pinion shaft assembly.

Replace worn or damaged parts.

(2) Check condition of pockets on chain sprocket (all capacities).

Replace worn or damaged parts.;

Contactor Assembly, Motor Rebuild

7-8. REBUILD OF CONTACTOR ASSEMBLY

Check for wear or damage to contactor parts

7-9. REBUILD OF SINGLE PHASE MOTOR ASSEMBLY

a. Disassembly

Inspect capacitor

Remove external retaining ring from end of shaft

Remove motor end bell from stator assembly

Remove internal retaining ring from bearing bore in end bell

b. Reassembly

5000 Hourly / 5 Yearly Hoist Assembly

INSPECTION: 5000 HOURS “ON” TIME OR 5 YEARS ELAPSED TIME.

Hoist must be removed from overhead suspension.

f. Reassemble Hoist.

Reassemble hoist from subassemblies following procedure outlined in paragraph 7-11.

7-11. REASSEMBLY OF HOIST FROM SUBASSEMBLIES.

a. General.

The procedure to be followed to reassemble the hoist from subassemblies is in reverse order of the disassembly steps outlined in paragraph 7-2.

Listed below are special assembly precautions which should be observed to assure proper assembly.

NOTE.

Parts for Budgit Portable Electric Hoist 1/4-Ton

Access the parts list for your equipment in MaintainX.

Hook Assembly-Upper With Latch (Includes Item 51) (Thru 1 Ton)

BH4007A

Hook Assembly-Upper With Latch (Includes Item 51) (Thru 1 Ton) Plated

BH-5027

Pin-Support, Chain Guide

BH-5009

Retaining Clip, Chain Guide Pin

BH-4008

Gasket-Gearcase

BH-1007

Hook Assembly-Upper With Latch (Includes Item 51) (Thru 1 Ton)

BH4007A

Hook Assembly-Upper With Latch (Includes Item 51) (Thru 1 Ton) Plated

BH-5027

Pin-Support, Chain Guide

BH-5009

Retaining Clip, Chain Guide Pin

BH-4008

Gasket-Gearcase

BH-1007

Hook Assembly-Upper With Latch (Includes Item 51) (Thru 1 Ton)

BH4007A

Hook Assembly-Upper With Latch (Includes Item 51) (Thru 1 Ton) Plated

BH-5027

Pin-Support, Chain Guide

BH-5009

Retaining Clip, Chain Guide Pin

BH-4008

Gasket-Gearcase

BH-1007

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX