Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

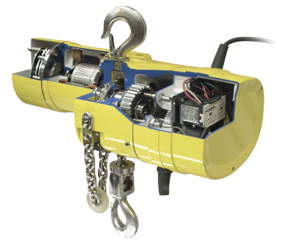

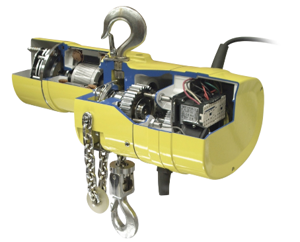

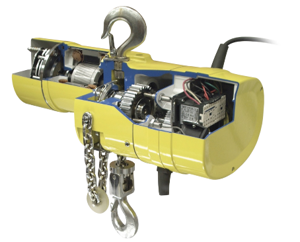

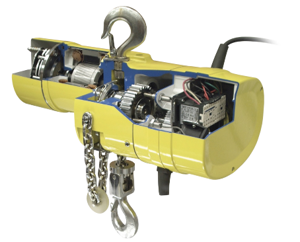

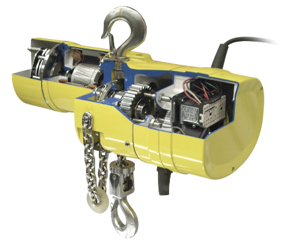

Manual for Budgit Air Chain Hoist 300 lbs

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Budgit Air Chain Hoist 300 lbs

Create an account to install this asset package.

Maintenance Plans for Budgit Air Chain Hoist Model 300 lbs

Integrate maintenance plans directly into your work orders in MaintainX.

1 Yearly Hoist Maintenance

Air Motor

Once a year, remove the air motor and check the condition of the bearings, rotor for possible rubbing on the body or end plates, free movement of the blades in rotor slots, seals and shims.; Replace worn or damaged parts.; If the motor appears to be in good condition, do not service other than lubricating well with light machine oil.

Pendant Throttle Control

Once a year, disassemble the pendant throttle control and check the condition of the springs, valves and levers.; Replace worn or damaged parts.; If the parts appear to be in good condition, do not service other than lubricating well with light machine oil.

Control Valve Assembly

Once a year, disassemble the control valve assembly and check the condition of the pistons, springs, spring seats, gasket, O-rings, valve bolts, air fittings and muffler.; Replace worn or damaged parts.; If the parts appear to be in good condition, do not service other than lubricating them with light machine oil.;

Hook Maintenance

Warning: This maintenance check requires trained personnel with PPE!

Hook free from chemical damage?

Hook free from deformations or cracks?

Measure the degree of twist from the plane of the unbent hook

Hook opening within acceptable limits?

Other load-sustaining components of the hoist free from damage?

Latch not damaged or bent?

Latch operates properly with sufficient spring pressure?

Sign off on the hook maintenance

6 Monthly Hoist Maintenance

Warning: This maintenance check requires trained personnel with PPE!

External evidence of loose screws.

External evidence of worn, corroded, cracked or distorted hook block, gears, bearings, chain stop and hook retainer.

External evidence of damage or excessive wear of the liftwheel or sheave (double reeved unit).

Check chain guide for wear or burring where the chain enters the hoist.

External evidence of excessive wear of brake parts.

Check the control station levers to make sure they operate freely and spring back when released.

Check air supply hose and control hose for kinks, cuts, leaks and damage.

Check the chain pin or dead end pin and chain stop for wear and cracks.

1 Daily Chain Maintenance

LOAD CHAIN

Chain feeds smoothly into and away from the hoist or hook block

Report if chain binds, jumps or is noisy

Chain Inspection

Chain cleaned with a non-caustic/non-acid type solvent

Link by link inspection for nicks, gouges, twisted links, weld spatter, corrosion pits, sitriations, cracks in weld areas, wear and stretching

Chain slack that normally passes over the lift wheel

Measure and record the stock diameter at the point of maximum wear of the link

Measure stock diameter in the same area on a link that does not pass over the liftwheel

1 Daily Hoist Maintenance

Warning: This maintenance check requires trained personnel with PPE!

Operate the hoist, with no load, and check for visual signs or abnormal noises which could indicate a potential problem

Brake for evidence of slippage

Chain for lubricant, wear, damaged links or foreign material

Hooks for damage, cracks, twist, latch engagement and latch operation

Report any deficiencies

Sign off on the hoist maintenance

Parts for Budgit Air Chain Hoist 300 lbs

Access the parts list for your equipment in MaintainX.

Main Frame

20367

Liftwheel Seal

20705

Protector Bearing

88636

Protector Assembly, 500# (Single Reeved) & 1000# Units

20645

Thrust Washer, Second Pinion

88640

Main Frame

20367

Liftwheel Seal

20705

Protector Bearing

88636

Protector Assembly, 500# (Single Reeved) & 1000# Units

20645

Thrust Washer, Second Pinion

88640

Main Frame

20367

Liftwheel Seal

20705

Protector Bearing

88636

Protector Assembly, 500# (Single Reeved) & 1000# Units

20645

Thrust Washer, Second Pinion

88640

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX