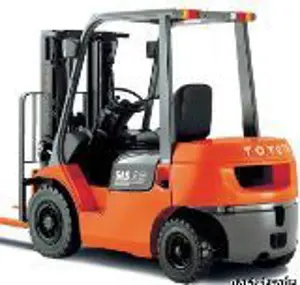

The Toyota Reach Lift Truck 7BRU23 is a versatile and efficient material handling solution designed for warehouse and industrial applications. Known for its reliability and advanced features, this lift truck enhances productivity while ensuring safety and ease of use in tight spaces.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Toyota Reach Lift Truck 7BRU23

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Toyota Reach Lift Truck 7BRU23

Create an account to install this asset package.

Maintenance Plans for Toyota Reach Lift Truck Model 7BRU23

Integrate maintenance plans directly into your work orders in MaintainX.

200 Hour / 1 Month Drive Unit Maintenance

Check the oil level of the drive housing

Check and clean the drive housing breather

Lubricate steering bearing via grease fittings

Sign off on the drive unit maintenance

1000 Hour / 6 Month Maintenance

Change the hydraulic filter

Change the hydraulic fluid

Separate the lift pump and motor

Lubricate the shaft with anti-seize lubricant

2000 Hour / 1 Year Maintenance

Change the drive unit fluid

Replace sideshift carriage pads

Sign off on the maintenance procedure

8 Hour / 1 Day Maintenance

Deadman pedal returns to up position when released in the brake system

Travel is cut out and brake is applied when deadman pedal is in fully raised position in the brake system

Forks inspected for damage, bending, cracking, or signs of unauthorized modification

Forks checked for minimum thickness

Hydraulic connections and hoses checked for leaks

Proper fluid level in hydraulic reservoir

Mast inspected for damage or binding

Each switch controls the assigned function

Intermittent switch operation

8 Hour / 1 Day Battery Check

Check cleanliness

Check the electrolyte level and specific gravity following the battery manufacturer’s instruction manual

Check the connector. Make sure all powered functions are shut down when disconnected

Check the battery gates. Be sure they are properly installed and locked securely in place

Check the free play of the battery. Be sure that it has no more than 0.50 in. (12.7 mm) of movement in any direction

Sign off on the battery check

200 Hour / 1 Month Overhead Guard System Maintenance

Check for physical damage to the guard

Replace the guard if it is structurally damaged

Check the torque of the overhead guard mounting bolts

Sign off on the overhead guard system maintenance

Parts for Toyota Reach Lift Truck 7BRU23

Access the parts list for your equipment in MaintainX.

Wrist Strap

00590-04848-71

Antistatic Field Service Kit

00590-04849-71

Wrist Strap Tester

00590-04850-71

Wrist Strap

00590-04848-71

Antistatic Field Service Kit

00590-04849-71

Wrist Strap Tester

00590-04850-71

Wrist Strap

00590-04848-71

Antistatic Field Service Kit

00590-04849-71

Wrist Strap Tester

00590-04850-71

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX