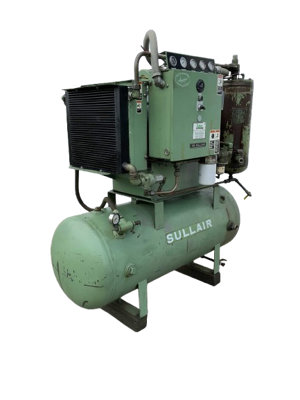

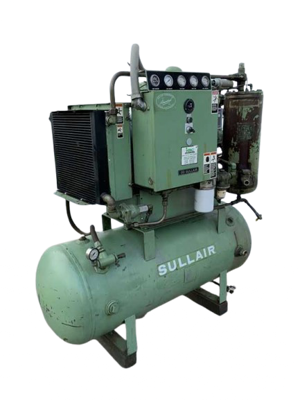

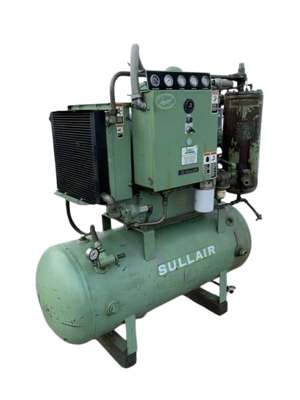

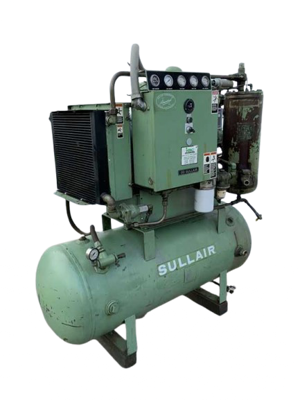

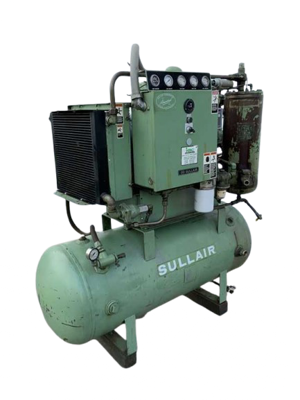

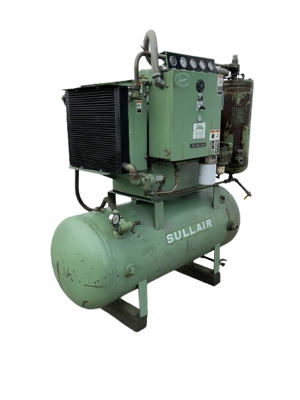

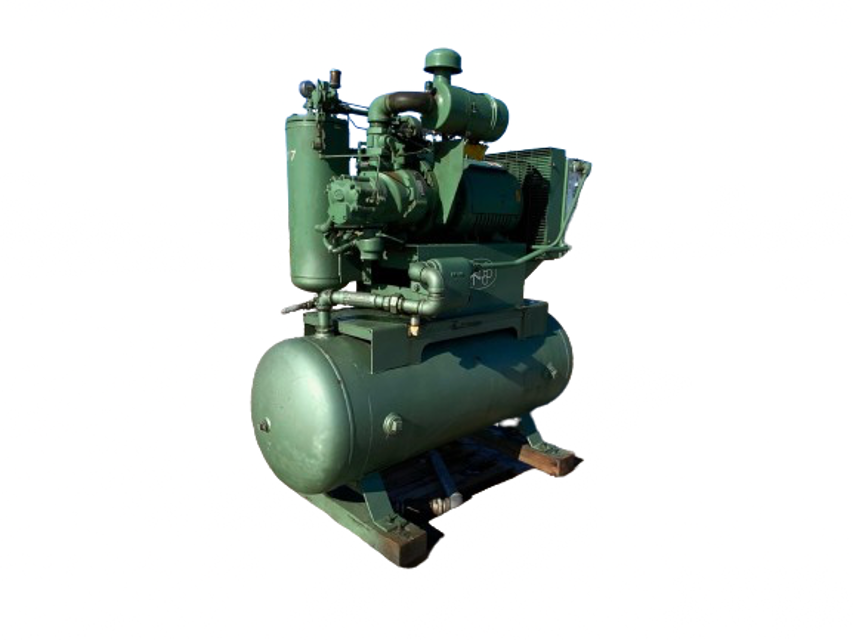

The Sullair Water-Cooled Compressor 10B 30HP-251327-004 WC is a robust industrial compressor designed for efficient cooling and air compression. Known for its reliability and performance, this model is ideal for various industrial applications requiring consistent air supply and cooling efficiency.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Sullair Water-Cooled Compressor 10B 30HP-251327-004 WC

Create an account to install this asset package.

Maintenance Plans for Sullair Water-Cooled Compressor Model 10B 30HP-251327-004 WC

Integrate maintenance plans directly into your work orders in MaintainX.

Compressor Blowdown Valve Maintenance

Warning: Always ensure the compressor is turned off and fully depressurized before starting maintenance.

Maintenance of Blowdown Valve No.250025-655

Unscrew end caps from the valve body and remove

Hold nut with an appropriate socket wrench and turn screw until loose

Remove all internal parts mounted on the machine screw. Remove the old o-rings and teflon seat and discard

Replace with the new o-rings and teflon seat provided in the repair kit. Apply appropriate lubricant to o-rings and valve body bore

Pre-assemble the internal parts for pilot (P) side of the valve onto the screw and install into the body

Assemble remaining internal parts for inlet (I) side to the screw as illustrated. Once assembled, install the locknut and torque to 25 in.-lbs. (2.82Nm)

Screw end caps into the valve body until tight

1 Yearly Separator Replacement

Select the correct repair kit

Pressure relieved from the sump tank and all compressor lines

All piping connected to the sump cover disconnected

Hex head capscrews from the cover plate loosened and removed

Cover plate lifted from the sump

Separator element removed

Old gasket material scraped from the cover and flange on the sump

New gaskets installed; one on the sump tank the other on top of the element

Separator element reinserted into the sump without denting it against the tank opening

Compressor Pressure Regulator Valve Maintenance

Repair pressure regulator valve 250017-280, use repair kit 250019-453

Loosen the locknut and turn the adjusting screw counterclockwise until the inner spring tension is relieved. The adjusting screw should turn freely when the spring tension is relieved

Remove the spring chamber from the body to allow access to internal parts

Remove the spring button and the spring. The dampener will stay inside the spring as it is removed. Leave the dampener inside the spring as there is no need to remove it

After removing the spring, remove the gasket stop and brass gasket

Remove the pressure plate nut and disassemble the pressure plate, diaphragm, diaphragm gasket (rubberized asbestos), seat disc and seat gasket

Remove and discard the seat ring

Reassemble the regulator using the new parts provided in the repair kit

Reassemble the diaphragm, pressure plate, gasket, seat disc, and seat disc gasket and tighten the nut. All of these parts with the exception of the pressure plate are provided in the repair kit

Compressor Control System Maintenance

Warning: This procedure requires trained personnel with PPE!

Adjust Control System with a desired operating range of 115 to 125 PSIG (792 to 862kPa). Differential is the difference between the high and low pressure settings. 10 PSIG (7kPa) is typical

Remove cover to pressure switch

Turn the range adjusting screw to the high pressure setting. Turning the screw counterclock-wise lowers both the high and low pressure equally

Differential is the difference between the high and low pressure settings. 10 PSIG (7kPa) is typical

Turn the differential adjusting screw to the lower (reset) setting. Turning the screw counterclock- wise widens the differential by lowering the reset (lower) setting only

When the pressure switch adjustment is complete, the pressure regulator should be adjusted for the pressure at which modulation of air delivery should begin. In this case that pressure will be 118 PSIG (824kPa). The regulator is adjusted by loosening the jam nut on the end of the cone shaped cover of the pressure regulator. When the jam nut is loose, turn the adjusting screw clockwise to increase or counterclockwise to decrease the setting

To set the regulator, continue closing the service valve, until the line pressure is 118 PSIG (824kPa). At this point regulator should pass a signal to the inlet valve to start closing it. If the line pressure keeps on rising or if the modulation does not begin, adjust the regulator valve as described above. After adjustment line pressure should be approximately 118 PSIG (824kPa) and 1.00 in. Hg vacuum below the inlet

Now close the service valve, line pressure will start rising. When line pressure reaches 125 lbs., the inlet valve will be closed to its maximum position. The inlet vacuum at this point will be around 25 in. Hg. The machine should unload at this point

Compressor Maintenance

PIPE END PREPARATION

Deburr and clean the pipe ends

Pipe ends free of all deep scratches, gouges, dents, etc.

JOINT INSTALLATION

Install the retainer (1), gasket (2), and sleeve (3) on one side of the pipe

Install the remaining retainer (4) and gasket (5) on the other pipe end

Position the retainer (4) and gasket to proper pipe insertion depth (“D”)

Slide the sleeve (3) to the gasket (5) and move gasket (2) and retainer (1) into position. The pipe MUST be inserted to the proper depth (“D”) into both gaskets

COUPLER INSTALLATION

Parts for Sullair Water-Cooled Compressor 10B 30HP-251327-004 WC

Access the parts list for your equipment in MaintainX.

Repair Kit

250019–453

Replacement Element

042445

Repair Kit

250034–112

Minimum Pressure Valve

241581

Repair Kit

250018–970

Repair Kit

250019–453

Replacement Element

042445

Repair Kit

250034–112

Minimum Pressure Valve

241581

Repair Kit

250018–970

Repair Kit

250019–453

Replacement Element

042445

Repair Kit

250034–112

Minimum Pressure Valve

241581

Repair Kit

250018–970

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX