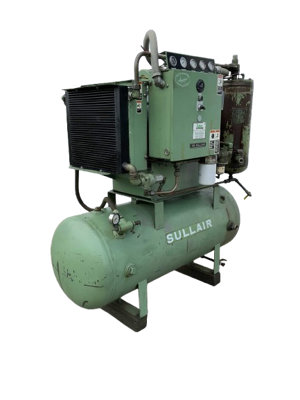

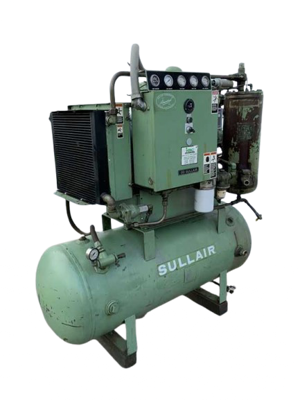

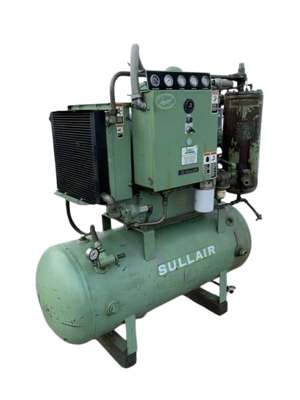

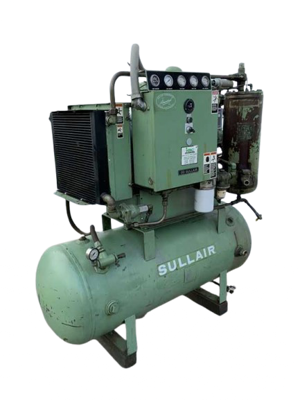

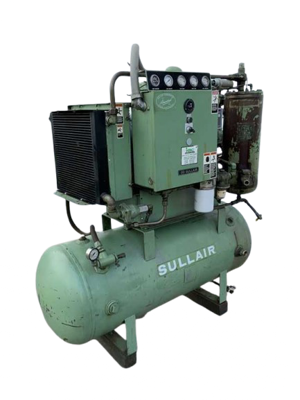

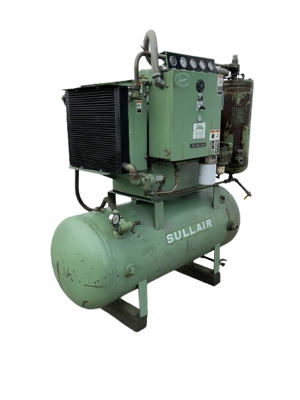

The Sullair Cycling Refrigerated Air Dryer SRC-325 is designed for efficient moisture removal from compressed air systems. This reliable asset ensures optimal performance and longevity, making it essential for industrial applications that require dry air. Regular maintenance enhances its efficiency and extends its service life.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Sullair Cycling Refrigerated Air Dryers SRC-325

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Sullair Cycling Refrigerated Air Dryers SRC-325

Create an account to install this asset package.

Maintenance Plans for Sullair Cycling Refrigerated Air Dryers Model SRC-325

Integrate maintenance plans directly into your work orders in MaintainX.

1 Daily Check

- Check the digital display for warnings or alarms.

- Verify the dew point on the digital display is between 35 -41 degrees F. Higher values may indicate operating conditions above the maximum ring of the dryer.

- Press the Drain button to verify the drain is functioning properly. A failure to open, or large volumes of condensate, may indicate improper functioning, an outlet blockage, backpressure, or inadequate interval and duration settings (when in Timed Operating mode).

1 Yearly Maintenance

- Replace pre and after-filter elements annually regardless of indicated pressure drop.

- Verify the presence of air leaks from flanges and joints.

- Verify the water piping is in good condition and check for water/glycol leaks.

- Do careful leak detection on joints, welds & service valves.

- Disassemble and clean (or replace) the condensate drain valve.

1 Weekly Check

- Verify that the ambient temperature is within the dryer's operating limits & that the dryer has adequate ventilation.

- Verify that the inlet conditions of flow; pressure and temperature are within the maximum rating for the dryer.

- Check the condenser pre-filter for excessive dust or debris & clean as necessary.;

4 Monthly Maintenance

- Check the differential pressure (or incident) monitors on the pre and after-filters. If the value is in the red, replace the elements.

- Check the refrigerant compressor discharge temperature (See Section 2.3).

- Verify the refrigerant piping is in good condition and check for the presence of ail stains, indicating a refrigerant leak.

- Blow compressed air backers through the condenser coils & condenser pre-filter to clean them. Use steam to remove oily deposits.

- Clean the condenser filters when the dryer is installed in dirty and dusty places.

- Clean the condensate strainer prior to the condensate drain valve.

- Check that the current drawing is within the limits specified for the unit.

- Check the tightness of the electrical cables on the terminal blocks and the main cables.

- Blow the dust off the contactors.

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX