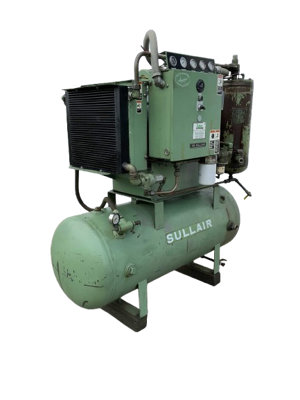

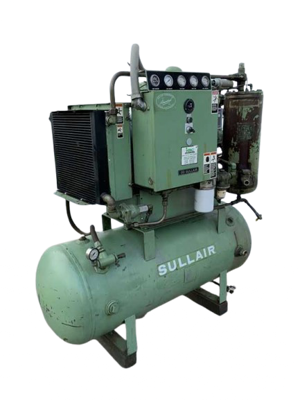

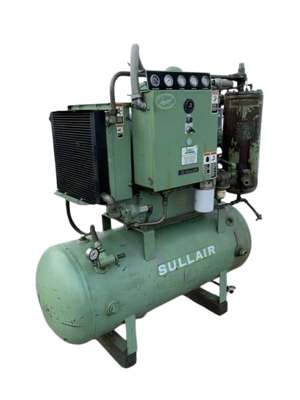

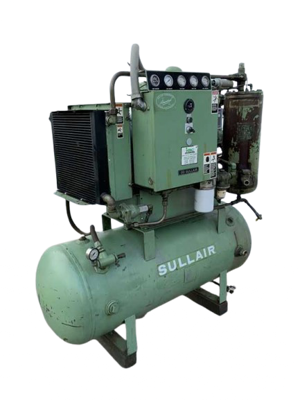

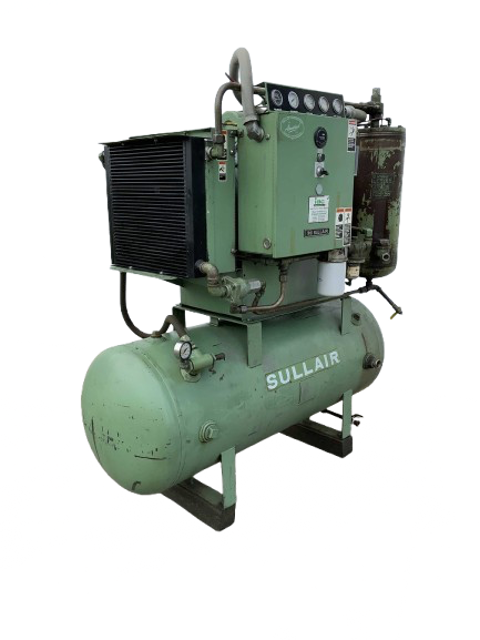

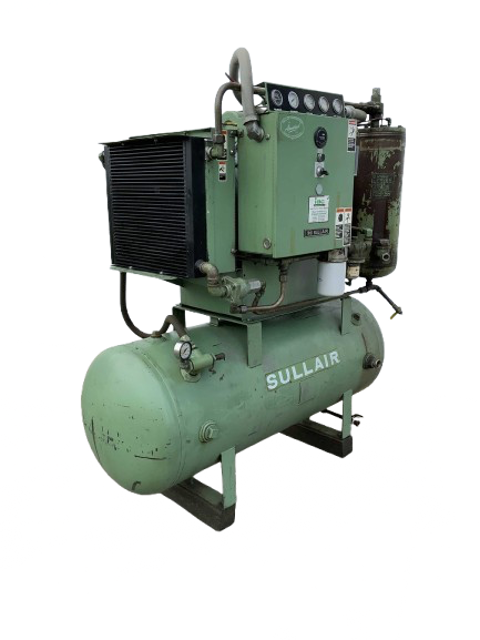

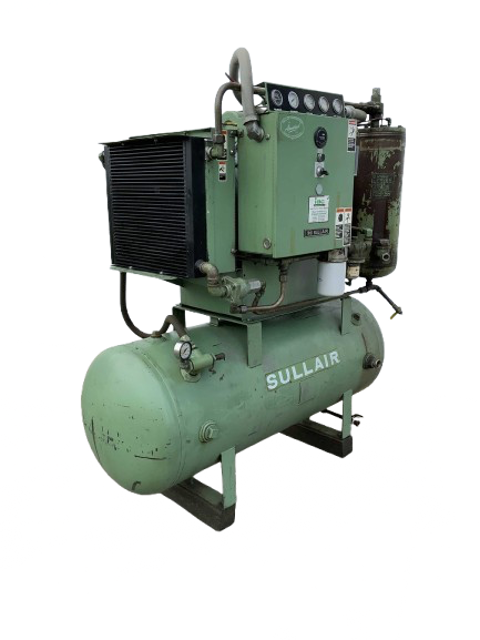

The Sullair Air-Cooled Compressor 10B 40HP-251325-003 AC is a robust and efficient industrial compressor designed for reliable performance in various applications. Known for its durability and ease of maintenance, this model ensures optimal air delivery and energy efficiency, making it a preferred choice for industrial operations.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Sullair Air-Cooled Compressor 10B 40HP-251325-003 AC

Create an account to install this asset package.

Maintenance Plans for Sullair Air-Cooled Compressor Model 10B 40HP-251325-003 AC

Integrate maintenance plans directly into your work orders in MaintainX.

1 Daily Compressor Maintenance

Check the fluid level in the sump. Should the level be low, simply add the necessary amount

Observe the gauges and indicators to be sure they monitor the correct readings for that particular phase of operation

Check on the overall compressor and gauges to assure that the compressor is running properly after it has warmed up

Clean the return line strainer after the initial 50 hours of operation

Clean the return line orifice after the initial 50 hours of operation

Compressor Control System Maintenance

Warning: This procedure requires trained personnel with PPE!

Control System adjusted to desired operating range of 115 to 125 PSIG (792 to 862kPa)?

FOR PRESSURE RANGE ADJUSTMENT:

Cover to pressure switch removed?

Range adjusting screw turned to the high pressure setting?

FOR DIFFERENTIAL ADJUSTMENT:

Differential adjusting screw turned to the lower (reset) setting?

Pressure switch adjustment complete?

Pressure regulator adjusted for the pressure at which modulation of air delivery should begin?

6 Monthly Air Filter Element Replacement

Clean exterior of air filter housing

Remove the air filter cover by loosening the wingnut securing the cover

Remove element and clean interior of housing using a damp cloth. DO NOT blow dirt out with compressed air

Clean or replace the element

Replace cover

Reset the filter maintenance indicator

Sign off on the air filter element replacement

Compressor Minimum Pressure/ Check Valve Maintenance

WARNING: Before performing maintenance on the valve, be sure that all pressure has been relieved in the compressor sump, and all downstream pressure has been vented to the atmosphere. Also be sure that the components of the compressor are cool to the touch

Unscrew the minimum pressure/check valve (P/N 241581) from the receiver cover

Remove the hexagonal retaining cap from the main body

Remove the flat washer and heavy spring from the main body

Tap the piston assembly (with a screwdriver) from the bottom of the main body and remove. The o-ring will now be seen easily

Remove the seal ring and discard

Clean piston assembly and valve thoroughly

Replace seal ring and coat the piston and seal with Parker Super “O” Ring Seal or an equivalent quality grease

WARNING: Extreme caution should be used when removing the cap from the body because there is spring tension on the cap

6 Monthly / 1000 Hours Compressor Maintenance

Clean the return line strainer

Replace the fluid filter element

Replace your fluid filter element and the gasket under any of the following conditions, whichever occur first

Conditions for replacing fluid filter element

To replace fluid filter element:

Using a strap wrench, remove the old element and gasket

Clean gasket seating surface

Apply a light film of fluid to the new gasket

Hand tighten new element until new gasket is seated in the gasket groove

Parts for Sullair Air-Cooled Compressor 10B 40HP-251325-003 AC

Access the parts list for your equipment in MaintainX.

Repair Kit

250034–114

Flexible Coupling

250007–544

Element

250025–525

Repair Kit

250019–451

Replacement Coil

250018–971

Repair Kit

250034–114

Flexible Coupling

250007–544

Element

250025–525

Repair Kit

250019–451

Replacement Coil

250018–971

Repair Kit

250034–114

Flexible Coupling

250007–544

Element

250025–525

Repair Kit

250019–451

Replacement Coil

250018–971

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX