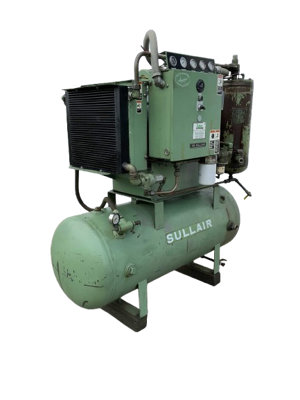

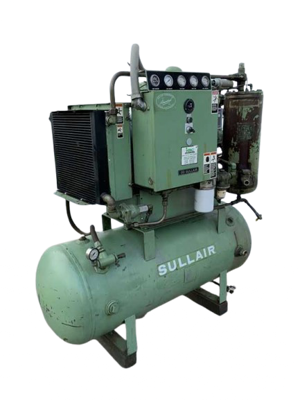

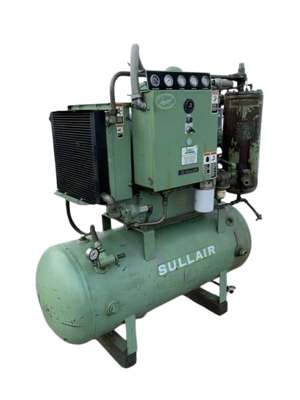

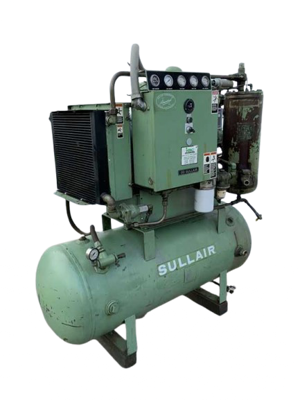

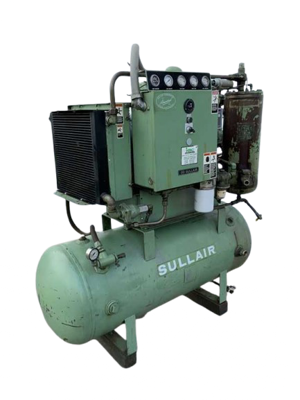

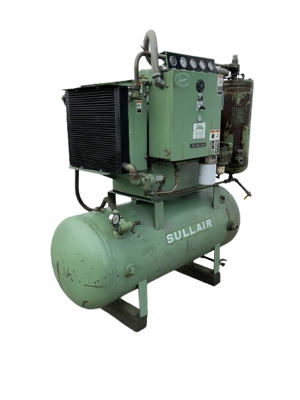

The Sullair Industrial Air Compressor 7510 is a robust and efficient solution for various industrial applications. Known for its reliability and performance, this model is designed to deliver consistent compressed air while minimizing downtime and maintenance costs. Ideal for demanding environments, it ensures optimal productivity and longevity.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Sullair Industrial Air Compressor 7510

Create an account to install this asset package.

Maintenance Plans for Sullair Industrial Air Compressor Model 7510

Integrate maintenance plans directly into your work orders in MaintainX.

Initial 50 Hours Compressor Maintenance

Warning: Ensure the compressor is turned off and cooled down before performing any maintenance tasks.

Is the compressor turned off and cooled down?

Maintenance Operations

Clean the return line strainer.

Refer to Maintenance Every 2000 Hours for location.

Clean the return line orifice.

Sign off on the initial 50 hours compressor maintenance

1 Yearly Air Filter Replacement

Does the maintenance gauge show red with the compressor running full load?

AIR FILTER ELEMENT REPLACEMENT

Clean the air filter’s exterior housing.

Release the hold-down clips and remove the end cover.

Remove the air filter element by pulling it out of the housing.

Clean the housing interior with a damp cloth. DO NOT blow dirt out with compressed air.

Replace the element.

Reassemble in the reverse order.

Sign off on the air filter replacement

1 Yearly Separator Replacement

Warning: Relieve all pressure from the receiver tank and all compressor lines before starting.

Pressure relieved from the receiver tank and all compressor lines?

Loosen and remove the eight (8) hex head capscrews (M12 x 40mm) from the cover plate.

Capscrews removed?

Lift the cover plate from the receiver tank.

Cover plate lifted?

Remove the separator elements.

Separator elements removed?

Inspect the receiver tank for rust, contamination, or damage.

Pressure Regulator Adjustment

Refer to Figure 6-5.

Start the compressor and adjust the service valve to maintain service air pressure at approximately 1 psi over its rated pressure.

Turn the inlet valve regulator adjusting screw until air just begins to escape from the control air orifice, located at the bottom of the regulator.

Lock the adjusting screw in place with the locknut.

The regulator is now properly set.

Sign off on the pressure regulator adjustment

2000 Hourly Fluid Return/Sight Glass Maintenance

The fluid return/sight glass subassembly is located on the side of the separator tank.

Fluid return/sight glass maintenance should be performed along with that of the fluid filter.

Fluid return/sight glass issues usually result from the condition of the filter assembly.

Order filter assembly No. 02250117-782, and use the following instructions as a guide:

Disconnect the tube at the bottom of the sight glass.

Unscrew the sight glass assembly where the elbow fitting joins the strainer/filter.

Remove the used filter assembly and replace it with the new assembly.

Inspect and clean the orifice inside the sight glass blocks. Remove the orifice with an Allen wrench.

Coat/lubricate the O-rings with silicone grease.

Parts for Sullair Industrial Air Compressor 7510

Access the parts list for your equipment in MaintainX.

Probe, Thermister 3000 OHM

02250155-175

Valve, Blowdown 1/2” 1.8:1

02250100-042

Valve, Minimum Pressure 100HP

02250109-817

Cooler, Oil/Water 6x36 1-5/8” SAE

02250120-863

Valve, Combo 24 VDC

02250170-783

Probe, Thermister 3000 OHM

02250155-175

Valve, Blowdown 1/2” 1.8:1

02250100-042

Valve, Minimum Pressure 100HP

02250109-817

Cooler, Oil/Water 6x36 1-5/8” SAE

02250120-863

Valve, Combo 24 VDC

02250170-783

Probe, Thermister 3000 OHM

02250155-175

Valve, Blowdown 1/2” 1.8:1

02250100-042

Valve, Minimum Pressure 100HP

02250109-817

Cooler, Oil/Water 6x36 1-5/8” SAE

02250120-863

Valve, Combo 24 VDC

02250170-783

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX