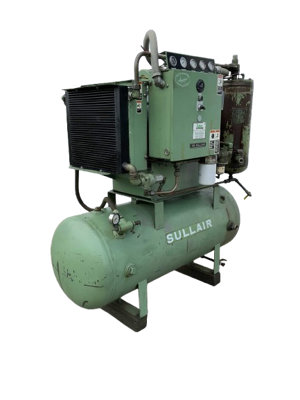

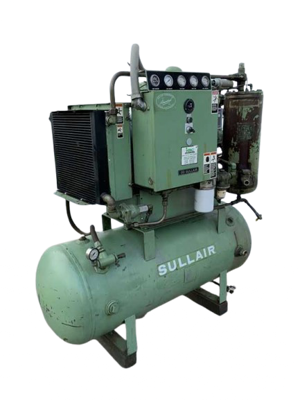

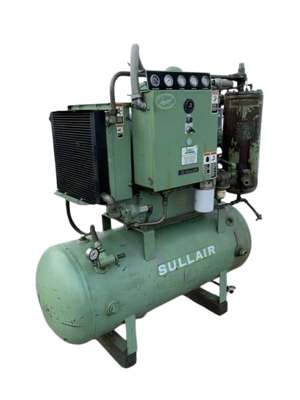

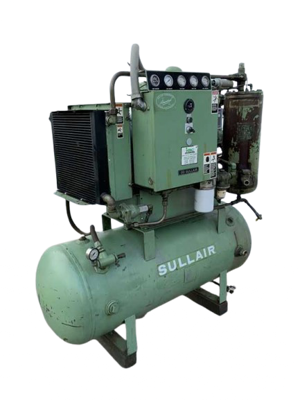

The Sullair Industrial Air Compressor 7509B AC is a robust and efficient air compressor designed for heavy-duty industrial applications. Known for its reliability and performance, this model ensures optimal air delivery and is essential for various manufacturing processes. Regular maintenance is crucial to maximize its lifespan and efficiency.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Sullair Industrial Air Compressor 7509B AC

Create an account to install this asset package.

Maintenance Plans for Sullair Industrial Air Compressor Model 7509B AC

Integrate maintenance plans directly into your work orders in MaintainX.

Initial 50 Hours Compressor Maintenance

After the initial 50 hours of operation, a few maintenance actions are required to clean the system of any foreign materials.

Clean the return line strainer. Refer to Maintenance Every 2000 Hours for location.

Clean the return line orifice.

Sign off on the initial 50 hours compressor maintenance

Pressure Regulator Adjustment

Refer to Figure 6-5.

Start the compressor and adjust the service valve to maintain service air pressure at approximately 1 psi over its rated pressure.

Turn the inlet valve regulator adjusting screw until air just begins to escape from the control air orifice, located at the bottom of the regulator.

Lock the adjusting screw in place with the locknut.

The regulator is now properly set.

Sign off on the pressure regulator adjustment

1 Yearly Control Line Strainer Cleaning

Warning: This procedure requires trained personnel with PPE!

Regulator and solenoid valve(s) are protected by a strainer

Strainer cleaned

Hex cap removed from the strainer

Strainer screen removed

Screen cleaned and reinstalled

Is the screen damaged?

If the screen is damaged, the strainer assembly must be replaced (P/N 241772)

Sign off on the strainer cleaning

Shaft Coupling Maintenance

Warning: This maintenance check requires trained personnel with PPE!

Is the elastomeric element worn or damaged?

If the elastomeric element is not worn or damaged, stop the procedure

Remove the protective grill from the adapter housing

Loosen the retaining screw located on the outer sleeve. Slide the sleeve to one side, exposing the coupling element

Unwrap the coupling element from the coupling jaws

Install the new element by wrapping it around the jaws, engaging the cogs on the element into the jaws

Tighten the two screws to 45 in·lbs (5 Nm)

Reinstall the protective grill

2000 Hourly Fluid Return/Sight Glass Maintenance

The fluid return/sight glass subassembly is located on the side of the separator tank.

Fluid return/sight glass maintenance should be performed along with that of the fluid filter.

Fluid return/sight glass issues usually result from the condition of the filter assembly.

Order filter assembly No. 02250117-782, and use the following instructions as a guide:

Disconnect the tube at the bottom of the sight glass.

Unscrew the sight glass assembly where the elbow fitting joins the strainer/filter.

Remove the used filter assembly and replace it with the new assembly.

Inspect and clean the orifice inside the sight glass blocks. Remove the orifice with an Allen wrench.

Coat/lubricate the O-rings with silicone grease.

Parts for Sullair Industrial Air Compressor 7509B AC

Access the parts list for your equipment in MaintainX.

Separator, Water SCWS-235N 2” L/AD

02250166-736

Gauge, Differential Pressure Z-Purge Assembly Regulator

02250078-976

Plug, Sight Glass 1-1/4” SAE

40029

Valve, Thermal 195 DEG 1-1/2”-18

02250092-081

Valve, Solenoid 2WNC 3/4 250# N4

250035-291

Separator, Water SCWS-235N 2” L/AD

02250166-736

Gauge, Differential Pressure Z-Purge Assembly Regulator

02250078-976

Plug, Sight Glass 1-1/4” SAE

40029

Valve, Thermal 195 DEG 1-1/2”-18

02250092-081

Valve, Solenoid 2WNC 3/4 250# N4

250035-291

Separator, Water SCWS-235N 2” L/AD

02250166-736

Gauge, Differential Pressure Z-Purge Assembly Regulator

02250078-976

Plug, Sight Glass 1-1/4” SAE

40029

Valve, Thermal 195 DEG 1-1/2”-18

02250092-081

Valve, Solenoid 2WNC 3/4 250# N4

250035-291

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX