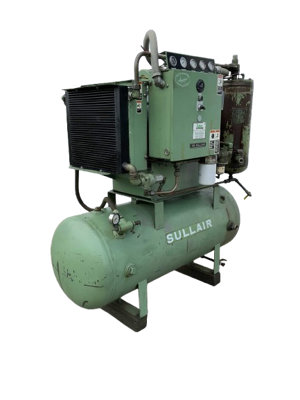

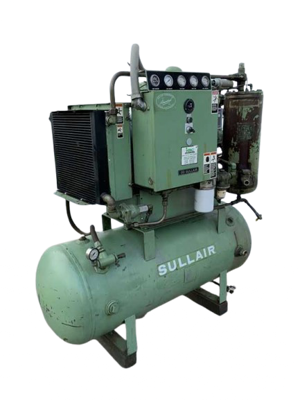

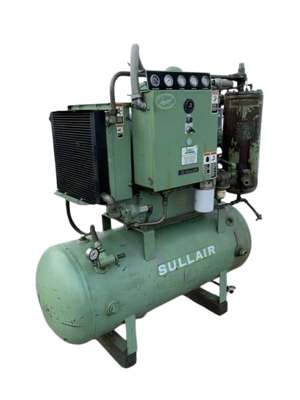

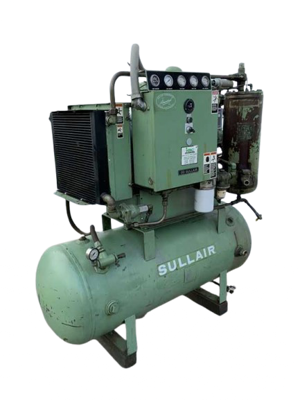

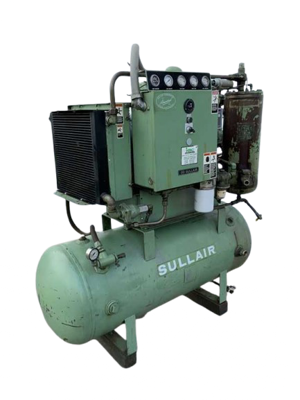

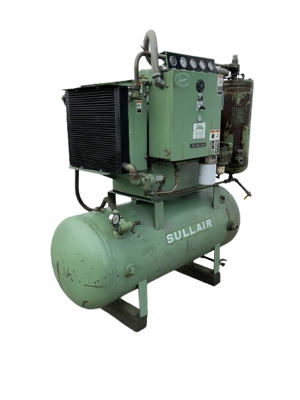

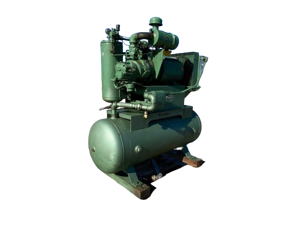

The Sullair Industrial Air Compressor 2212 is a robust and efficient solution for various industrial applications. Known for its reliability and performance, this model ensures optimal air delivery and is designed for easy maintenance, making it a preferred choice for businesses seeking durable air compression solutions.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Sullair Industrial Air Compressor 2212

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Sullair Industrial Air Compressor 2212

Create an account to install this asset package.

Maintenance Plans for Sullair Industrial Air Compressor Model 2212

Integrate maintenance plans directly into your work orders in MaintainX.

2000 Hourly Fluid Filter Replacement

WS Controller indicates filter replacement

Fluid change required

Fluid Filter Element Replacement

Filter canister removed with a wrench

Filter element removed and disposed of legally

Gasket seating surface cleaned

Light film of fluid applied to the element seal

Element installed into the filter canister

Tighten the canister to the filter head to 10 to 12 ft·lb (13.5 to 16.2 N·m)

1 Yearly / 8000 Hourly Fluid Replacement

Warning: Do not mix different types of fluids.

Contamination of non-detergent mineral fluids with traces of detergent motor fluids may lead to operational problems such as foaming, filter plugging, orifice or line plugging.

Note: Flush system when switching lubricant brands.

When ambient conditions exceed those noted or if conditions warrant use of 'extended' life lubricants contact Sullair for recommendation.

Drain the separator/sump tank

Change the compressor fluid using instructions shown in Application Guide on page 24.

Participate in a fluid analysis program with the fluid suppliers?

If yes, provide details of the fluid analysis program

Disconnect lubricant hose from the thermal valve

Pressure Regulator Adjustment

Start the compressor and adjust the service valve to maintain service air pressure approximately at 1 psi over rated pressure.

Turn the inlet valve regulator adjusting screw until air just begins to escape from the control air orifice (located at the bottom of the regulator; refer to Figure 6-5).

Lock the adjusting screw in place with the locknut.

The regulator is now properly set.;

1 Yearly Air Filter Replacement

Maintenance indicator shows red with the compressor running full load?

If the filter needs to be replaced, order a replacement element.

Clean exterior of air filter housing.

Rotate end cover counterclockwise and remove.

Remove air filter element by pulling it out of the housing.

Clean interior of housing using a damp cloth. DO NOT blow dirt out with compressed air.

At this time replace the element.

Reassemble in the reverse order of the disassembly.

Sign off on the air filter replacement

Shaft Coupling Maintenance

The compressor unit and motor are rigidly connected via a mounting adapter housing.

This arrangement makes coupling alignment unnecessary.

The coupling is a jaw type in shear. If the elastomeric element requires replacement due to wear or breakage, order replacement element no. 02250152-669, and follow the following steps:

1. Remove the protective grill from the adapter housing.

2. Loosen the retaining screw located on the outer sleeve. Slide the sleeve to one side, exposing the coupling element.

3. Unwrap the coupling element from the coupling jaws.

4. Install the new element by wrapping it around the jaws, engaging the cogs on the element into the jaws.

5. Reinstall the outer sleeve and torque the securing screws to 10 in·lb (1.13 N·m). Install the protective grill.;

Parts for Sullair Industrial Air Compressor 2212

Access the parts list for your equipment in MaintainX.

Valve, Ball/Strainer Combo-1/2”NPT

02250182-548

Valve, Shuttle 1/4” (Double Check)

408893

Tank, Separator 2200

02250155-599

Gauge, Differential Pressure Z-PRG Assembly Bottom

02250169-612

Probe, Thermister 3000 OHM NTC 12’L

02250175-087

Valve, Ball/Strainer Combo-1/2”NPT

02250182-548

Valve, Shuttle 1/4” (Double Check)

408893

Tank, Separator 2200

02250155-599

Gauge, Differential Pressure Z-PRG Assembly Bottom

02250169-612

Probe, Thermister 3000 OHM NTC 12’L

02250175-087

Valve, Ball/Strainer Combo-1/2”NPT

02250182-548

Valve, Shuttle 1/4” (Double Check)

408893

Tank, Separator 2200

02250155-599

Gauge, Differential Pressure Z-PRG Assembly Bottom

02250169-612

Probe, Thermister 3000 OHM NTC 12’L

02250175-087

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX