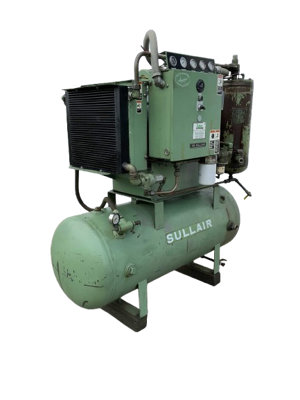

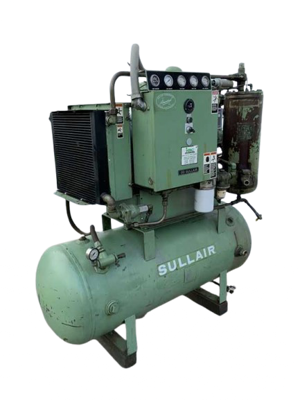

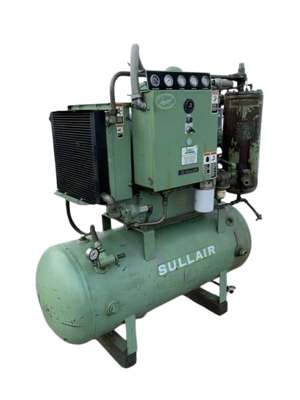

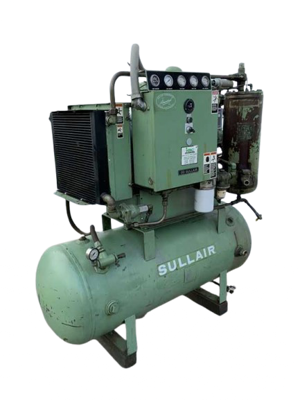

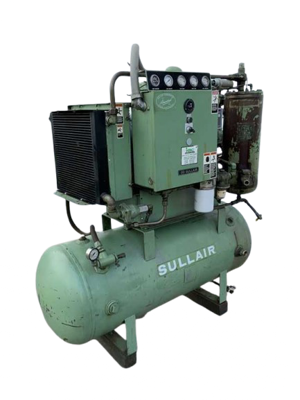

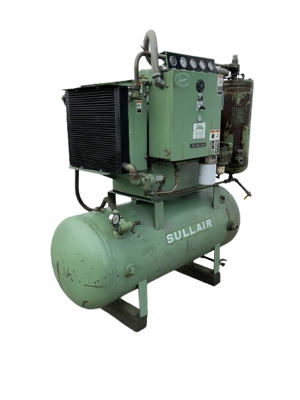

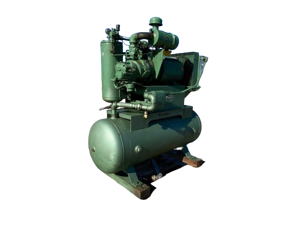

The Sullair Industrial Air Compressor 2209V AC is a robust and efficient solution for various industrial applications. Known for its reliability and performance, this model is designed to deliver consistent compressed air while minimizing downtime and maintenance costs. Ideal for demanding environments, it ensures optimal productivity and efficiency.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Sullair Industrial Air Compressor 2209V AC

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Sullair Industrial Air Compressor 2209V AC

Create an account to install this asset package.

Maintenance Plans for Sullair Industrial Air Compressor Model 2209V AC

Integrate maintenance plans directly into your work orders in MaintainX.

2000 Hourly Compressor Maintenance

Cleaned the return line strainer?

Replaced the fluid filter element?

Pulled oil sample for analysis?

Checked air filter?

Change air filter if necessary?

Initial 50 Hours Compressor Maintenance

Warning: Ensure the compressor is turned off and cooled down before performing any maintenance tasks.

Clean the return line strainer.

Upload a photo of the cleaned return line strainer.

Clean the return line orifice.

Upload a photo of the cleaned return line orifice.

Sign off on the initial 50 hours compressor maintenance.

2000 Hourly Fluid Filter Replacement

WS Controller indicates filter replacement

Fluid change

Fluid Filter Element Replacement

Filter canister removed with a wrench

Filter element removed and disposed

Gasket seating surface cleaned

Light film of fluid applied to the element seal

Element installed into the filter canister

Tighten the canister to the filter head to 10 to 12 ft·lb (13.5 to 16.2 N·m)

Pressure Regulator Adjustment

Warning: This procedure should be performed by trained personnel only.

Is the compressor started?

Enter the service air pressure

Is the service air pressure approximately 1 psi over rated pressure?

Did you turn the inlet valve regulator adjusting screw until air just begins to escape from the control air orifice?

Did you lock the adjusting screw in place with the locknut?

Is the regulator now properly set?

Sign off on the pressure regulator adjustment

1 Daily Compressor Inspection

Warning: HIGH-PRESSURE HAZARD! DO NOT remove caps, plugs, and/or other components when compressor is running or pressurized. Stop compressor and relieve all internal pressure before doing so. Failure to comply could result in death or serious injury.

Fluid level in the separator/sump tank is sufficient

If fluid level is low, enter the amount of fluid added

Is the addition of fluid becoming too frequent?

If the addition of fluid becomes too frequent, refer to Section 6.9: Troubleshooting—Introduction on page 61 under EXCESSIVE COMPRESSOR FLUID CONSUMPTION for a probable cause and remedy.

Controller display monitors the correct readings for their particular phase of operation

Compressor is running properly after warming up

Sign off on the daily compressor inspection

Parts for Sullair Industrial Air Compressor 2209V AC

Access the parts list for your equipment in MaintainX.

Motor

MTR_VAR

Separator, Water SCWS-235N 1” L/AD

02250167-115

Switch, Differential Pressure 20 PSID

02250050-154

Probe, Thermister 3000 OHM NTC 12’L

02250175-087

Valve, Pressure Regulator

250017-280

Motor

MTR_VAR

Separator, Water SCWS-235N 1” L/AD

02250167-115

Switch, Differential Pressure 20 PSID

02250050-154

Probe, Thermister 3000 OHM NTC 12’L

02250175-087

Valve, Pressure Regulator

250017-280

Motor

MTR_VAR

Separator, Water SCWS-235N 1” L/AD

02250167-115

Switch, Differential Pressure 20 PSID

02250050-154

Probe, Thermister 3000 OHM NTC 12’L

02250175-087

Valve, Pressure Regulator

250017-280

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX