Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for SPX Corporation Rotary Pump R3RI

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

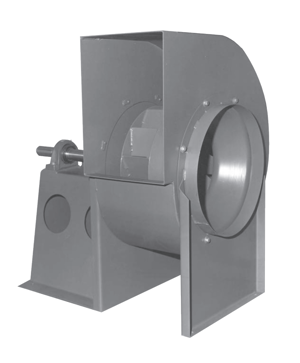

SPX Corporation Rotary Pump R3RI

Create an account to install this asset package.

Maintenance Plans for SPX Corporation Rotary Pump Model R3RI

Integrate maintenance plans directly into your work orders in MaintainX.

Rotary Pump Inspection

1. APV equipment is inspected prior to shipment. When leaving the factory, it is well crated for normal transportation procedures. APV cannot, however, guarantee safe arrival. Therefore, upon receipt of this equipment, check the received items against the packing list for damage or missing parts. Check the packing material thoroughly for small parts.

2. Visually inspect for damage or loss. Damage or loss should be reported immediately to the delivery carrier while present. Following the immediate notication of the lost or damaged parts, a detailed description including quantity, description of the loss or damage, and a cash value should be claimed against the carrier with respect to the guidelines set forth by the responsible carrier’s policies.

APV’s responsibility terminates F.O.B point of manufacture unless otherwise specied per the General Terms and Conditions of Sale as published by APV and amended from time to time. Contact APV Order Services if shipping information is required for handling claims.

3. In the case of damage or loss to the equipment, APV may perform three major functions:

a. Manufacturer Function – APV manufactures quality equipment and stands behind the APV Standard Warranty. Refer to the Standard Warranty.

b. Assessor Function – APV oers assessment services for ling claims. The APV assessor will accurately determine the extent of the damage (or loss) and cost of repairs to the equipment. Reimbursement for this service will be agreed upon prior to the assessment.

c. Repair House Function – APV oers services for repairing the damage(s) or replacement of loss(es) to the equipment. APV has the option to alter the Standard Warranty on refurbished or replacement parts. The cost of this service will be dependent upon the assessment that is made.;

1 Daily Rotary Pump Check

Drain accumulated condensate from crankcase

Lubricate rotors with food grade lubricant

Wash pump body surfaces

Lubricate outboard bearings

CIP pump (without rotors in place)

Replace pump cover gasket

Lubricate shaft seals with food grade lubricant

Rotary Pump Check

Warning: Disassemble pump before checking rotation

Discharge on the right when the top rotor turns clockwise

Discharge on the left when the top rotor turns counterclockwise

Two seal pressure relief grooves on the discharge side of the pump

Pump body and pump cover mounted in the correct position

Hex shaped stud in the upper left hand position

Discharge taken off the right

If discharge on the left is desired, the hex stud must be interchanged with the corresponding lower right hand stud

Hex stud interchanged for left discharge

Flanged Hopper Cleaning

Warning: This cleaning procedure requires trained personnel with PPE!

Rotors and cover removed from the pump?

Rotors and cover washed separately?

Hot water applied to the underside of the pump?

Product contact surfaces washed with hot water?

Rotors and cover put back on pump?

Rotors slide in freely without rubbing or contacting the edge of the cavity?

Sign off on the flanged hopper cleaning

Initial Rotary Pump Cleaning

Warning: Many of the commonly used chemical solutions could cause severe injury to personnel if contacted. The hazard is especially severe for eyes, skin, or inhalation.

Prior to using any rotary pump for the first time, disassemble and hand clean the pump. Clean all inner and outer surfaces to remove any dirt, grit or film that may have accumulated during shipment and installation.

Did you use carbon steel wool?

Did you use water high in iron, salt or sulfur?

Did you allow cleaners or bactericides to remain on surface for over 15 minutes?

Did you rinse all parts and surfaces exposed to corrosive cleaning solutions completely with cold water?

Did you allow tools or other metal items to lie on wet stainless steel?

Select the cleaners used

If rust or discoloration occurred, did you polish the affected area immediately to prevent the condition from progressing?

Parts for SPX Corporation Rotary Pump R3RI

Access the parts list for your equipment in MaintainX.

Nut - Hex, Stainless Steel

M523V006529

Nut - Wing

M727P39782E

Cover - Standard Flat Cover

M03HP13588

Gasket - Cover (Paper), Sold In Pks Of 100pcs

M541P13075

Bearing - Seal, Stainless Steel

M03HP137173

Nut - Hex, Stainless Steel

M523V006529

Nut - Wing

M727P39782E

Cover - Standard Flat Cover

M03HP13588

Gasket - Cover (Paper), Sold In Pks Of 100pcs

M541P13075

Bearing - Seal, Stainless Steel

M03HP137173

Nut - Hex, Stainless Steel

M523V006529

Nut - Wing

M727P39782E

Cover - Standard Flat Cover

M03HP13588

Gasket - Cover (Paper), Sold In Pks Of 100pcs

M541P13075

Bearing - Seal, Stainless Steel

M03HP137173

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX