Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

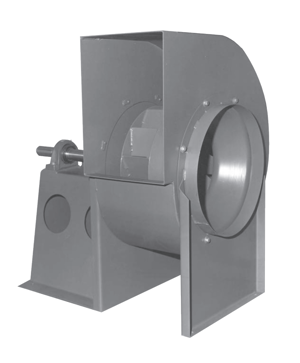

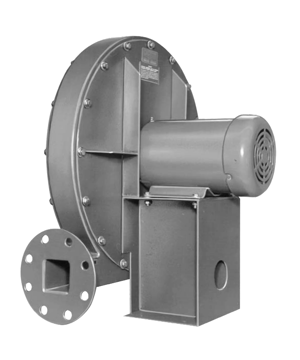

Manual for SPX Corporation Rotary Pump R6

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

SPX Corporation Rotary Pump R6

Create an account to install this asset package.

Maintenance Plans for SPX Corporation Rotary Pump Model R6

Integrate maintenance plans directly into your work orders in MaintainX.

Vented Cover Adjustment

- Manual:

Pump discharge pressure tends to push the rubber cover gasket and plunger towards the front of the pump. This pressure compresses spring allowing pressure to be relieved by escaping via the rear side of the gasket and the recess of the outer cover. The venting pressure can be set by adjusting spring tension with the adjusting nut.

1. Place a pressure gauge in the downstream line close to the pump; between the pump and other downstream equipment.

2. Place a shut-o valve in the discharge line immediately downstream from the pressure gauge. Leave the valve wide open.

3. Loosen the lock nut and turn the adjusting nut clockwise as far as it will go. This is to prevent any venting during Step 4 below.

4. Pump product through system at the desired temperature and adjust the pump speed until the desired capacity is attained.

5. Check the pressure gauge for the desired pumping pressure. Example: 40 psig (2.8 kg/cm2).

6. Determine the venting pressure needed to protect the system. Example: 45 psig (3.15 kg/cm2). Venting pressure must always be higher than the pumping pressure.

7. Now turn the adjusting nut counterclockwise until only two or three threads are engaged.

1 Monthly Rotary Pump Check

Check condition of V belts

Check bearings and oil seals for wear

Check pump interior and cover for wear

Check rotors for wear

Check driven and drive pulleys for wear

Check overall condition of drive units

Make sure oil is changed regularly in drive units

Check shafts and rotor hubs for wear - corners must be square

Sign off on the monthly rotary pump check

1 Daily Rotary Pump Cleaning

Warning: Use of chemical solutions could cause severe injury to personnel if contacted. The hazard is especially severe for eyes, skin, or inhalation.

Rubber mat placed under the immediate area of the pump?

R1, R2, R3 and R3HD Pumps: Removed the four hex nuts, cover and gasket from the pump body?

R4, R4HD, R6 and R6HD Pumps: Removed the eight hex nuts, cover and gasket from the pump body?

Removed the two rotors from the pump shafts?

R1, R2, R3 and R3HD Pumps: Installed the gasket, cover and four hex nuts on the pump body and tightened the hex nuts?

R4, R4HD, R6 and R6HD Pumps: Installed the gasket, cover and eight hex nuts on the pump body and tightened the hex nuts?

Rinsed outer areas of the pump and gearcase (hand clean if necessary) according to standard plant procedure?

R1, R2, R3 and R3HD Pumps: When CIP of the system is completed, removed the four hex nuts, cover and gasket from the pump body and replaced the used gasket?

Rotary Pump Bearing Adjustment

Loosen the set screws and the top and bottom bearing adjusting nuts

Rotate the top shaft back and forth and tighten the top bearing adjusting nut until a slight resistance is felt

Mark the position of the top bearing adjusting nut and back it off one-half turn

Rotate the bottom shaft back and forth and tighten the bottom bearing adjusting nut until a slight resistance is felt

Lock the bottom bearing adjusting nut set screw after adjusting

Turn the top bearing adjusting nut so that the marks line up

Lock the top bearing adjusting nut set screw after aligning marks

If bearing adjustment has been performed and the shafts are still loose, replace the bearing

Rotate the shafts back and forth 180o during bearing adjustment

Flanged Hopper Cleaning

Warning: This cleaning procedure requires trained personnel with PPE!

Rotors and cover removed from the pump?

Rotors and cover washed separately?

Hot water applied to the underside of the pump?

Product contact surfaces washed with hot water?

Rotors and cover put back on pump?

Rotors slide in freely without rubbing or contacting the edge of the cavity?

Sign off on the flanged hopper cleaning

Parts for SPX Corporation Rotary Pump R6

Access the parts list for your equipment in MaintainX.

Nut - Hex, Stainless Steel

M523V006529

Nut - Wing, Optional

M727P39782E

Cover - Standard Front Cover

M03HP133615

Gasket - Cover (Paper), Sold In Pks Of 100

M541P133610

Bearing - Seal, Stainless Steel

M03HP137734

Nut - Hex, Stainless Steel

M523V006529

Nut - Wing, Optional

M727P39782E

Cover - Standard Front Cover

M03HP133615

Gasket - Cover (Paper), Sold In Pks Of 100

M541P133610

Bearing - Seal, Stainless Steel

M03HP137734

Nut - Hex, Stainless Steel

M523V006529

Nut - Wing, Optional

M727P39782E

Cover - Standard Front Cover

M03HP133615

Gasket - Cover (Paper), Sold In Pks Of 100

M541P133610

Bearing - Seal, Stainless Steel

M03HP137734

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX