Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

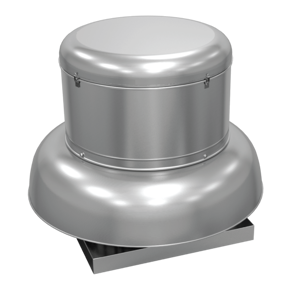

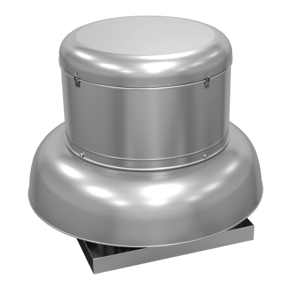

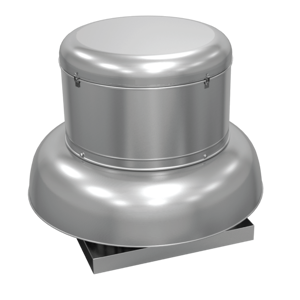

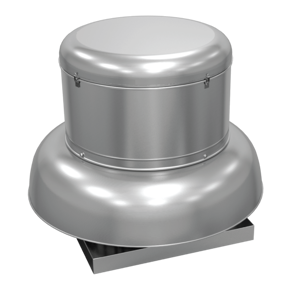

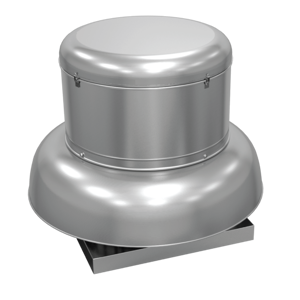

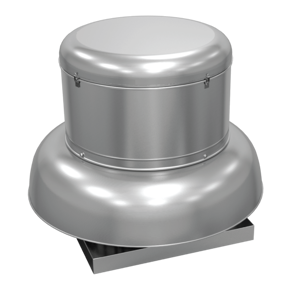

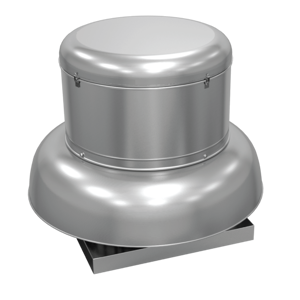

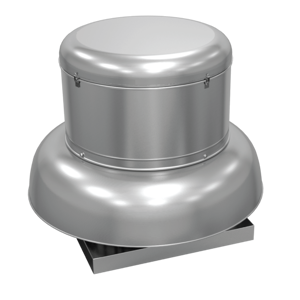

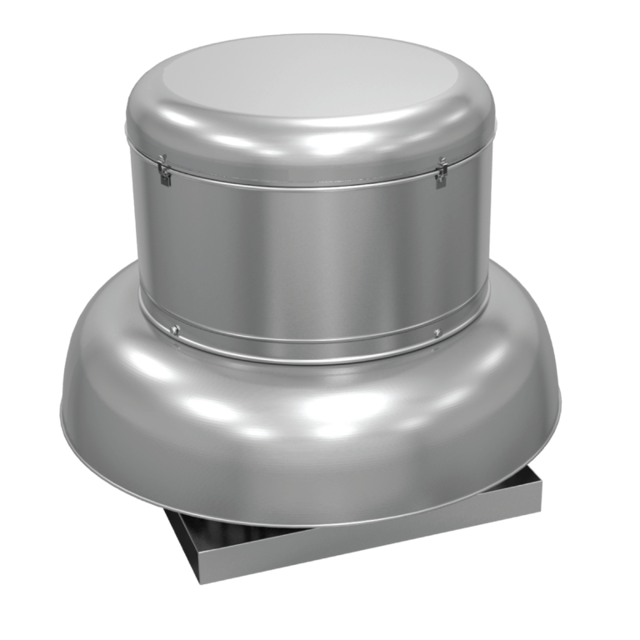

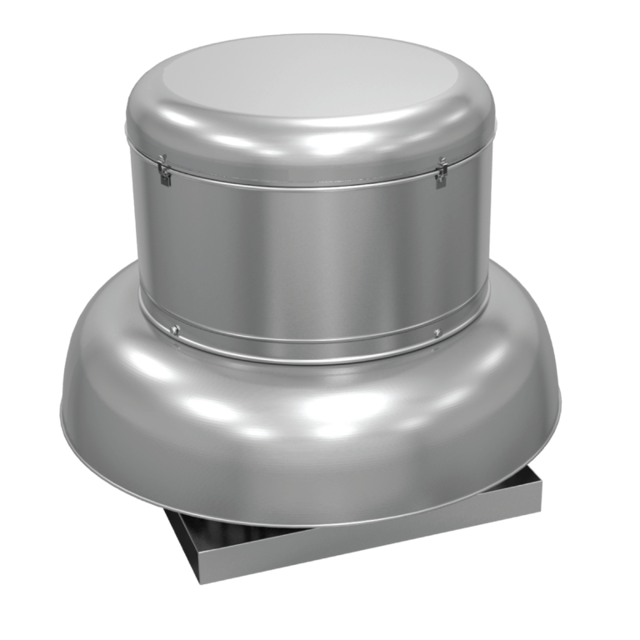

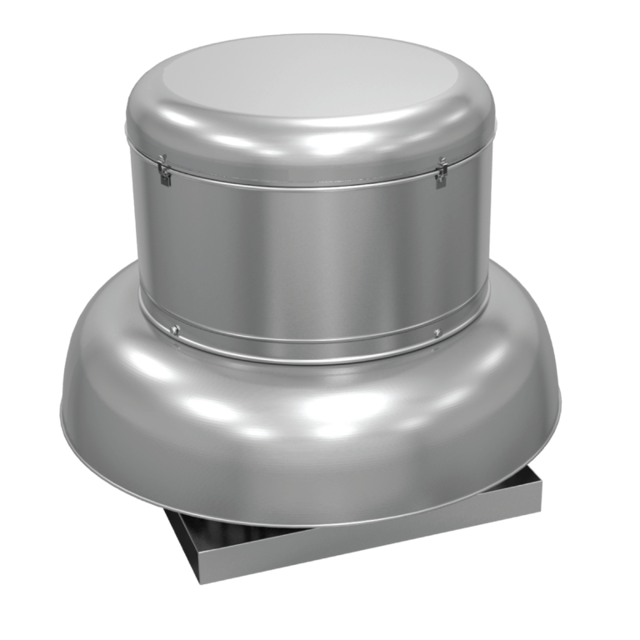

Manual for Loren Cook Company AC Exhauster ACW-B

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Loren Cook Company AC Exhauster ACW-B

Create an account to install this asset package.

Maintenance Plans for Loren Cook Company AC Exhauster Model ACW-B

Integrate maintenance plans directly into your work orders in MaintainX.

3 Yearly Motor Bearings Lubrication

Warning: This procedure requires trained personnel with PPE!

Is the motor a Direct Drive 1050/1075,1200,1300 &1500 rpm unit?

If yes, proceed with the following steps. If not, skip to step 7.

Has the unit been stored for a year or more?

Enter the number of LIGHT grade mineral oil or SAE 10W oil drops added (up to 30 drops)

Sign off on the lubrication of Direct Drive 1050/1075,1200,1300 &1500 rpm units

Does the motor have grease lubricated ball or roller bearings without provisions for relubrication?

If yes, contact the maintenance department to disassemble and lubricate the bearings. If not, proceed to step 10.

Sign off on the maintenance department's lubrication of grease lubricated ball or roller bearings without provisions for relubrication

Fan Bearing Replacement

Warning: This procedure requires trained personnel with PPE!

Old bearing removed

Burrs removed from the shaft by sanding

New bearings slid onto the shaft and loosely mounted onto the bearing support

Wheel correctly positioned and bearing bolts securely tightened to the bearing support

Setscrews aligned bearing to bearing and secured tightly to the shaft

NOTICE! Never tighten both pairs of setscrews before securing bearing mounting bolts. This may damage the shaft.

Wheel position inspected again and readjusted if necessary

Sign off on the fan bearing replacement

Initial 30 Minutes Fan Inspection

Warning: Stop the fan before inspection

Fan stopped for inspection?

Bolts inspected and tightened as necessary?

Setscrews inspected and tightened as necessary?

Motor mounting bolts inspected and tightened as necessary?

Sign off on the fan inspection

Initial 8 Hours Fan Inspection

Inspection of the fan should be conducted at the first 8 hour interval of satisfactory operation.

During the inspections, stop the fan and inspect as instructed.

8 Hour Interval

Inspect belt alignment and tension. Adjust and tighten as necessary.;

Fan Bearings Lubrication

NOTICE! The fan bearings are provided prelubricated. Any specialized lubrication instructions on fan labels supersedes information provided herein.

Bearing grease is a petroleum lubricant in a lithium base conforming to a NLGI #2 consistency. If user desires to utilize another type of lubricant, they take responsibility for flushing bearings and lines, and maintaining a lubricant that is compatible with the installation.

A NLGI #2 grease is a light viscosity, low-torque, rust-inhibiting lubricant that is water resistant. Its temperature range is from -30°F to 200°F and capable of intermittent highs of 250°F.

Bearings should be relubricated in accordance with the condition chart. See Condition Chart.

Is the fan in operation?

For best results, lubricate the bearing while the fan is in operation. Pump grease in slowly until a slight bead forms around the bearing seals. Excessive grease can damage seal and reduce life through excess contamination and/or loss of lubricant.

Did a slight bead form around the bearing seals?

In the event that the bearing cannot be seen, use no more than three injections with a hand operated grease gun.

Number of injections used

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX