Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

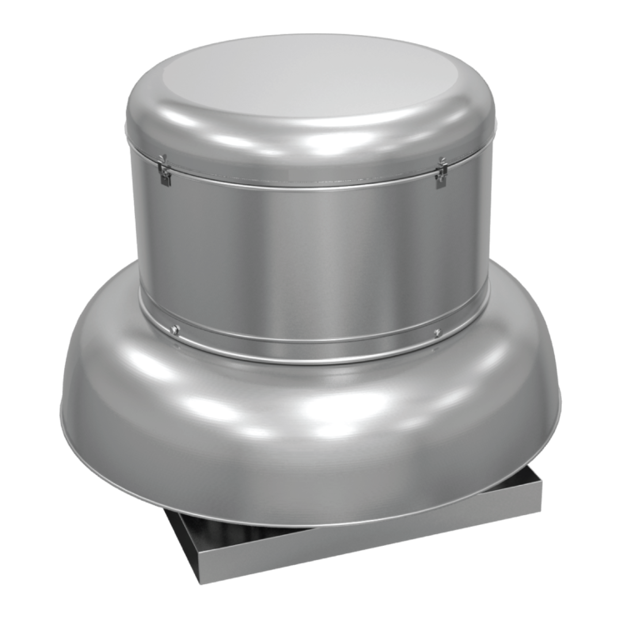

Manual for Loren Cook Company AC Exhauster ACRU-D

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Loren Cook Company AC Exhauster ACRU-D

Create an account to install this asset package.

Maintenance Plans for Loren Cook Company AC Exhauster Model ACRU-D

Integrate maintenance plans directly into your work orders in MaintainX.

6 Monthly Fan Inspection

It is recommended the following inspections be conducted twice per year.

• Inspect bolts and setscrews for tightness. Tighten as necessary. Refer to Torque chart.

• Inspect belt wear and alignment. Replace worn belts with new belts and adjust alignment as needed. Refer to Belt and Pulley Installation, page 4.

• Bearings should be inspected as recommended in the Conditions Chart.

• Inspect for cleanliness. Clean exterior surfaces only. Removing dust and grease on motor housing assures proper motor cooling.;

3 Yearly Motor Bearings Lubrication

Warning: This procedure requires trained personnel with PPE!

Is the motor a Direct Drive 1050/1075,1200,1300 &1500 rpm unit?

If yes, proceed with the following steps. If not, skip to step 7.

Has the unit been stored for a year or more?

Is the unit in severe conditions?

Add LIGHT grade mineral oil or SAE 10W oil up to 30 drops.

Does the motor have grease lubricated ball or roller bearings without provisions for relubrication?

If yes, contact the maintenance department to disassemble and lubricate the bearings. If not, proceed to step 10.

For motors with provisions for relubrication, follow intervals of the table Relubrication Intervals.

Initial AC Fan Inspection

Warning: Handle the AC fan and accessories with care during inspection

AC fan and accessories free of damage

AC fan wheel turns freely and does not bind when turned by hand

Dampers (if included) have free operation of all moving parts

Record any visible sign of damage on the Delivery Receipt

Sign off on the initial AC fan inspection

Initial 8 Hours Fan Inspection

Inspection of the fan should be conducted at the first 8 hour interval of satisfactory operation.

During the inspections, stop the fan and inspect as instructed.

8 Hour Interval

Inspect belt alignment and tension. Adjust and tighten as necessary.;

Initial 30 Minutes Fan Inspection

Warning: Stop the fan before inspection!

Fan stopped for inspection?

Bolts inspected and tightened as necessary?

Setscrews inspected and tightened as necessary?

Motor mounting bolts inspected and tightened as necessary?

Sign off on the fan inspection

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX