Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

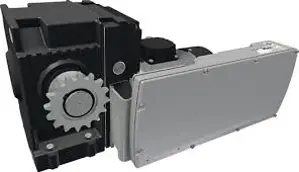

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

JLG Scissor Lift 2632ES

Create an account to install this asset package.

Maintenance Plans for JLG Scissor Lift Model 2632ES

Integrate maintenance plans directly into your work orders in MaintainX.

Wheel And Tire Replacement

Tire Wear and Damage

Inspect tires periodically for wear or damage. Tires with worn edges or distorted profiles require replacement. Tires with significant damage in the tread area or side wall, require immediate evaluation before placing the machine into service.

Replacement wheels must have the same diameter and profile as the original. Replacement tires must be the same size and rating as the tire being replaced.

It is extremely important to apply and maintain proper wheel mounting torque.

WHEEL NUTS MUST BE INSTALLED AND MAINTAINED AT THE PROPER TORQUE TO PREVENT LOOSE WHEELS, BROKEN STUDS, AND POSSIBLE SEPARATION OF WHEEL FROM THE AXLE.

BE SURE TO USE ONLY THE NUTS MATCHED TO THE CONE ANGLE OF THE WHEEL.

Tighten the lug nuts to the proper torque to prevent wheels from coming loose. Use a torque wrench to tighten the fasteners.

If you do not have a torque wrench, tighten the fasteners with a lug wrench, then immediately have a service garage or dealer tighten the lug nuts to the proper torque.

Over-tightening will result in breaking the studs or permanently deforming the mounting stud holes in the wheels.

1 Yearly Machine Inspection

Warning: TO AVOID POSSIBLE INJURY, BE SURE MACHINE POWER IS “OFF” DURING WALK-AROUND INSPECTION.

Notice! DO NOT OVERLOOK VISUAL INSPECTION OF CHASSIS UNDERSIDE. CHECKING THIS AREA OFTEN RESULTS IN DISCOVERY OF CONDITIONS WHICH COULD CAUSE EXTENSIVE MACHINE DAMAGE.

Cleanliness – Check all surfaces for leakage (oil, fuel, or battery fluid) or foreign objects.

Structure – Inspect the machine structure for dents, damage, weld or parent metal cracks or other discrepancies.

Decals and Placards – Check all for cleanliness and legibility. Make sure none of the decals and placards are missing.

Operation and Safety Manuals – Make sure a copy of the Operation and Safety Manual is enclosed in the weather resistant storage container.

Walk-Around Inspection

Platform Control Console - Placard secure and legible, control lever and switches return to neutral, control lever lock and emergency stop switch function properly, manual in storage box.

Steer Cylinder

6 Monthly Lower And Upper Slide Pads Lubrication

Maintenance Hazards

Shut off power to all controls and ensure that all moving parts are secured from inadvertent motion prior to performing any adjustments or repairs.

Never work under an elevated platform until it has been fully lowered to the full down position, if possible, or otherwise supported and restrained from movement with appropriate safety props, blocking, or overhead supports.

DO NOT attempt to repair or tighten any hydraulic hoses or fittings while the machine is powered on or when the hydraulic system is under pressure.

Always relieve hydraulic pressure from all hydraulic circuits before loosening or removing hydraulic components.

DO NOT use your hand to check for leaks. Use a piece of cardboard or paper to search for leaks. Wear gloves to help protect hands from spraying fluid.

Ensure replacement parts or components are identical or equivalent to original parts or components.

Never attempt to move heavy parts without the aid of a mechanical device. Do not allow heavy objects to rest in an unstable position. Ensure adequate support is provided when raising components of the machine.

Use only approved non-flammable cleaning solvents.

Scissor Lift Function Check

Perform the Function Check as follows:

1. From the ground control console with no load in the platform:

a. Check that all guards protecting the function control switches and controllers are in place.

b. Operate all functions and check all limiting and cutout switches.

c. Check manual descent.

d. Ensure that all machine functions are disabled when the Emergency Stop Button is depressed.

2. From the platform control console:

a. Ensure that the control console is firmly secured in the proper location.

b. Check that all guards protecting the function control switches and controllers are in place

Scissor Lift Pre-Delivery Inspection

Cleanliness – Check all surfaces for leakage (oil, fuel, or battery fluid) or foreign objects.

Structure – Inspect the machine structure for dents, damage, weld or parent metal cracks or other discrepancies.

Decals and Placards – Check all for cleanliness and legibility. Make sure none of the decals and placards are missing.

Operation and Safety Manuals – Make sure a copy of the Operation and Safety Manual is enclosed in the weather resistant storage container.

Walk-Around Inspection

Platform Control Console - Placard secure and legible, control lever and switches return to neutral, control lever lock and emergency stop switch function properly, manual in storage box.

Steer Cylinder - See Inspection Note.

Spindle, Tie Rod, Drive Motor and Steer Linkage (left front) - See Inspection Note.

Wheels and Tires - Properly secured, no missing lug nuts. Refer to Section 6, Tires and Wheels. Inspect wheels for damage and corrosion.

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX