Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

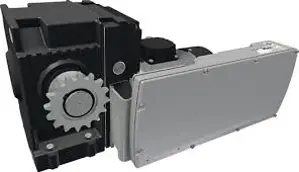

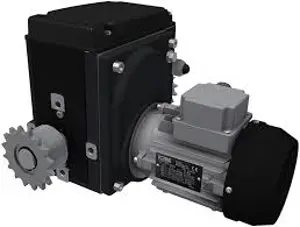

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Topcon Total Station IS-01

Create an account to install this asset package.

Maintenance Plans for Topcon Total Station Model IS-01

Integrate maintenance plans directly into your work orders in MaintainX.

Optical Plummet Telescope Adjusting

Warning: This procedure requires trained personnel!

Adjustment section cover of the optical plummet telescope eyepiece removed?

Four capstan adjustment screws exposed?

Center mark shifted to the point using the accessory adjusting pin?

Point and center mark coincided using the leveling screws?

Instrument rotated 180° or 200G around the vertical axis?

Center mark checked after rotation?

Capstan adjustment screw loosened on the side to which the center mark must be moved?

Adjustment screw on the opposite side tightened by an equal amount?

Theodolite Adjusting

Pointers on the Adjustment

Eyepiece of the telescope adjusted properly

Adjustments carried out in the correct sequence

Adjustment screws tightened securely

Attachment screws tightened sufficiently

Checking operations repeated after adjustments

Notes on the Tribrach

Tribrach installed firmly

No slack between the leveling screws and the base

Vertical Angle 0 Datum Adjusting

Level the instrument properly with the plate level.

Press the [ADJUST] icon.

Press the [V ANGLE 0 ADJUST] key.

Collimate target A from the telescope properly in normal setting.

Press the [SET] key.

Collimate target A in reverse telescope setting.

Press the [SET] key. Measured value is set and carry out adjustment mode.

Check that the total amount of normal and reverse angular travel is 360° collimating the target A by normal and reverse positions.

Sign off on the Vertical Angle 0 Datum Adjusting

Compensation Systematic Error Adjusting

Level the instrument properly with the plate level

Press the [ADJUST] icon from the main menu

Press the [3AXIS COMPENSATION] key

Press the [ADJUST] key

Collimate target A (around 0° in horizontal within ±3°) in normal telescope setting

Press the [SET] key ten times

Turn the telescope in reverse telescope setting

Collimate target A in reverse telescope setting

Press the [SET] key ten times

Laser Pointer Optical Axis Adjusting

Warning: This procedure requires trained personnel with PPE!

Rubber caps removed from the top of the instrument

Hexagonal wrench used to adjust screws A, B, and C

Laser pointer adjusted to coincide with the point of intersection

Screws A, B, and C tightened equally

Rubber caps of the adjustment screws not lost

Operation keys placed on the telescope eyepiece side

Laser pointer turned on

Sign off on the laser pointer optical axis adjustment

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX