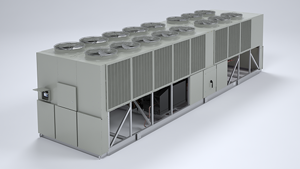

The Hypertherm Welding Inverter PowerMax 65 is a high-performance plasma cutting system designed for precision and efficiency. This versatile model is ideal for various industrial applications, offering reliable operation and ease of use for professionals in the welding industry.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Hypertherm Hypertherm Welding Inverter PowerMax 65 PowerMax 65

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Hypertherm Hypertherm Welding Inverter PowerMax 65 PowerMax 65

Create an account to install this asset package.

Maintenance Plans for Hypertherm Hypertherm Welding Inverter PowerMax 65 Model PowerMax 65

Integrate maintenance plans directly into your work orders in MaintainX.

Inverter Inspection

DANGER! Disconnect the electrical power before you perform any maintenance. All work that requires removal of the power supply cover must be performed by a qualified technician.

Check indicator lights and fault icons

Correct any fault conditions

Inspect the consumables for proper installation and wear

Technician's Signature

3 Monthly Inverter Maintenance

Replace any damaged labels

Inspect the trigger for damage

Inspect the torch body for cracks and exposed wires. Replace any damaged parts

Inspect the power cord and plug. Replace if damaged

Inspect the torch lead. Replace if damaged

Clean the inside of the power supply with compressed air or a vacuum every 6 Months;

Air Filter Element Replacement

Turn OFF the power, disconnect the power cord, and make sure the gas supply is disconnected. Position the rear of the power supply so the removable air filter bowl is easily accessible

If the consumables case is positioned next to the air filter bowl, remove it first

Grasp the filter bowl with your right hand. Push down the thumb latch and rotate the filter bowl approximately 45 degrees to the right

Pull the filter bowl straight down to remove

Install the air filter element (for plastic or nylon bowl)

Twist and pull up on the black element retainer at the top of the filter bowl

Gently twist the black element retainers until they come apart and you can remove the dirty air filter element from them

Twist the element retainers until they lock together and fit snugly against the new element

NOTE! If the black element retainers are damaged, order a new air filter assembly in kit 428351

Parts for Hypertherm Hypertherm Welding Inverter PowerMax 65 PowerMax 65

Access the parts list for your equipment in MaintainX.

Optional Remote-Start Pendant 75 Foot (23 M)

128652

Cable (7.6 M, 25 Ft)

023206

CSA Rear Panel

228645

CE Rear Panel

228646

75° Hand Torch Assembly With 7.6 M (25 Ft) Lead

059473

Optional Remote-Start Pendant 75 Foot (23 M)

128652

Cable (7.6 M, 25 Ft)

023206

CSA Rear Panel

228645

CE Rear Panel

228646

75° Hand Torch Assembly With 7.6 M (25 Ft) Lead

059473

Optional Remote-Start Pendant 75 Foot (23 M)

128652

Cable (7.6 M, 25 Ft)

023206

CSA Rear Panel

228645

CE Rear Panel

228646

75° Hand Torch Assembly With 7.6 M (25 Ft) Lead

059473

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX