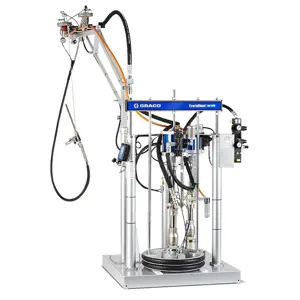

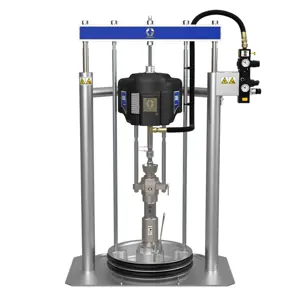

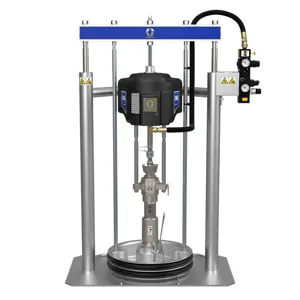

The Graco Pump System 24F089 is a reliable industrial pump designed for efficient fluid transfer and handling. Known for its durability and performance, this pump system is ideal for various applications, ensuring optimal operation and maintenance practices for longevity and reliability.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Graco Pump System 24F089

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Graco Pump System 24F089

Create an account to install this asset package.

Maintenance Plans for Graco Pump System Model 24F089

Integrate maintenance plans directly into your work orders in MaintainX.

Power Supply Replacement

⚠️ All electrical wiring must be completed by a qualified electrician and comply with all local codes and regulations.

Wall Power Supply and Filter

1. Follow Before Servicing, page 13. Disconnect main power.

2. Open Control Box.

3. Disconnect the three input wires from the line filter (403).

4. See Fig. 8. Disconnect the power supply CAN cable (401a) from the advanced fluid control module (302).

5. Disconnect line filter wires and power supply wires from the power switch (402).

6. Disconnect the power supply ground wire, PS(GND), from the advanced fluid control module ground terminal (T).

7. Remove four screws (405) and remove power supply (401). If replacing filter, remove two screws (407) and the filter (403).

1 Monthly Air Filter Maintenance

⚠️ Removing a pressurized air filter bowl could cause serious injury. Depressurize air line before servicing.

Pump systems have two air filters: the 5 micron air manifold filter (209) and the 40 micron pump air filter (206). Meter systems have only the 5 micron filter (209). Check filters daily and replace element(s) as needed. Order 15D909 (5 micron) or 15D890 (40 micron).

Close main air shutoff valve on air supply line and on system. Depressurize air line.

Remove the filter cover (A).

Unscrew the filter bowl (B).

Remove and replace element (206a, 209a).

Screw filter bowl (B) on securely. Install cover (A).

Note: Check Fluid Filter Daily.

Advanced Fluid Control Module (AFCM) Replacement

Follow Before Servicing, page 13. Disconnect main power.

Control Box opened

All cables from AFCM (302) removed and cable locations noted

Ground wire disconnected from ground screw (GS)

Four mounting screws (303) loosened

AFCM slid up and out of keyhole slots

Follow steps in reverse order to install a new AFCM. See electrical schematic for cable connection information.

Follow instructions in Manual 3A1244 to update the software on the new AFCM.

Control Box closed and power restored

Pump Maintenance

Displacement Pump Removal

Pressure relief procedure followed

Upload a photo of the disconnected fluid line from the pump outlet

Tie rod shield (26) removed for Merkur Pumps or coupler shield (79) removed for Merkur Bellows Pumps

Coupling nut (16) loosened

Coupling collars (15) removed and coupling nut (16) lifted up

TSL reservoir (25) removed for Merkur Pumps

Tie rod nuts (14) removed

Displacement pump removed with the pump adapter attached

Alternator Regulator Replacement

Follow Before Servicing, page 13. Disconnect main air.

Open Control Box.

Disconnect supply air line from regulator assembly (505).

Loosen air regulator swivel fittings (506) and remove from solenoid module.

Repair or replace alternator regulator parts as necessary. See Alternator Power Assembly, page 46, for repair parts. Replace air regulator swivel fitting (506).

Reconnect air line. Set regulator air pressure to 18 psi (0.12 MPa, 1.2 bar).

NOTICE: To avoid damage to the alternator, do not set the regulator air pressure higher than 18 psi (0.12 MPa, 1.2 bar).

Close Control Box and restore power.

Sign off on the alternator regulator replacement

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX