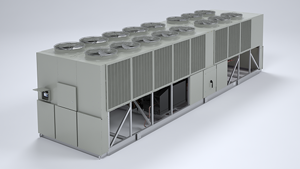

The Ex-Trafire Plasma Torch 85HD is a high-performance plasma cutting tool designed for precision and efficiency in industrial applications. Known for its reliability and advanced features, this model is ideal for professionals seeking superior cutting capabilities and durability in demanding environments.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Ex-Trafire Ex-Trafire Plasma Torch 85HD 85HD

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Ex-Trafire Ex-Trafire Plasma Torch 85HD 85HD

Create an account to install this asset package.

Maintenance Plans for Ex-Trafire Ex-Trafire Plasma Torch 85HD Model 85HD

Integrate maintenance plans directly into your work orders in MaintainX.

1 Yearly Plasma Torch Maintenance

WARNING! Electric shock due to missing grounding. If the cover plates are improperly mounted, the grounding may not be properly established. There is a risk of life threatening electric shock.

The cover plates may be disassembled and assembled only by a qualified electrician for maintenance and cleaning work.

Each time the cover plates are opened, have a safety inspection performed in accordance with IEC 60974 Part 4: “Periodic inspection and testing” by Thermacut® or another authorized specialist.

WARNING! Electric shock due to live parts. Fatal electric shock can occur if components are live during maintenance and cleaning work.

Set the POWER switch to OFF before maintenance and cleaning work.

Disconnect the input power supply from the wall.

Observe the Log-out/Tag-out procedure.

Safety inspection performed by Thermacut® or a trained technician.

Sign off on the plasma torch maintenance

1 Weekly Plasma Torch Check

WARNING! Electric shock due to missing grounding. If the cover plates are improperly mounted, the grounding may not be properly established. There is a risk of life threatening electric shock.

The cover plates may be disassembled and assembled only by a qualified electrician for maintenance and cleaning work.

Each time the cover plates are opened, have a safety inspection performed in accordance with IEC 60974 Part 4: “Periodic inspection and testing” by Thermacut® or another authorized specialist.

WARNING! Electric shock due to live parts. Fatal electric shock can occur if components are live during maintenance and cleaning work.

Set the POWER switch to OFF before maintenance and cleaning work.

Disconnect the input power supply from the wall.

Observe the Log-out/Tag-out procedure.

Check the cap sensor.

3 Monthly Plasma Torch Check

WARNING! Electric shock due to missing grounding. If the cover plates are improperly mounted, the grounding may not be properly established. There is a risk of life threatening electric shock. The cover plates may be disassembled and assembled only by a qualified electrician for maintenance and cleaning work. Each time the cover plates are opened, have a safety inspection performed in accordance with IEC 60974 Part 4: “Periodic inspection and testing” by Thermacut® or another authorized specialist.

WARNING! Electric shock due to live parts. Fatal electric shock can occur if components are live during maintenance and cleaning work. Set the POWER switch to OFF before maintenance and cleaning work. Disconnect the input power supply from the wall. Observe the Log-out/Tag-out procedure.

Check the cutting torch for signs of cracks in the torch body and exposed wires.

Check the gas hose, filter elements and connections for leaks.

Open the body of the EX-TRAFIRE®85HD and have the inside cleaned with a vacuum cleaner or dry, clean compressed air by Thermacut® or a trained technician.

Sign off on the plasma torch check

1 Daily / 6 Hourly Plasma Torch Check

WARNING! Electric shock due to missing grounding. If the cover plates are improperly mounted, the grounding may not be properly established. There is a risk of life threatening electric shock. The cover plates may be disassembled and assembled only by a qualified electrician for maintenance and cleaning work. Each time the cover plates are opened, have a safety inspection performed in accordance with IEC 60974 Part 4: “Periodic inspection and testing” by Thermacut® or another authorized specialist.

WARNING! Electric shock due to live parts. Fatal electric shock can occur if components are live during maintenance and cleaning work. Set the POWER switch to OFF before maintenance and cleaning work. Disconnect the input power supply from the wall. Observe the Log-out/Tag-out procedure.

Gas settings checked

Cables, connector hoses, and connections checked for tight fit and damage

Work lead clamp checked for contamination

Cutting torch's consumables checked for wear

Sign off on the plasma torch check

Parts for Ex-Trafire Ex-Trafire Plasma Torch 85HD 85HD

Access the parts list for your equipment in MaintainX.

FHT-EX 105TTH Hand Cutting Torch Without consumables with 49.2 ft (15 m) cable/TCS13

EX-5-139-003

Shield 40/45 A, SmoothLine, machine

EX-5-422-050

FHT-EX 105TTH Hand Cutting Torch Without consumables with 26.2 ft (8 m) cable/TCS13

EX-5-139-002

Starter Kit 75A For FHT-EX 105TTM Machine Torch

EX-5-433-052

FHT-EX 105TTM Machine Torch Without Gear Rack Without consumables, with 26.2 ft (8 m) cable/ TCS13

EX-5-204-031

FHT-EX 105TTH Hand Cutting Torch Without consumables with 49.2 ft (15 m) cable/TCS13

EX-5-139-003

Shield 40/45 A, SmoothLine, machine

EX-5-422-050

FHT-EX 105TTH Hand Cutting Torch Without consumables with 26.2 ft (8 m) cable/TCS13

EX-5-139-002

Starter Kit 75A For FHT-EX 105TTM Machine Torch

EX-5-433-052

FHT-EX 105TTM Machine Torch Without Gear Rack Without consumables, with 26.2 ft (8 m) cable/ TCS13

EX-5-204-031

FHT-EX 105TTH Hand Cutting Torch Without consumables with 49.2 ft (15 m) cable/TCS13

EX-5-139-003

Shield 40/45 A, SmoothLine, machine

EX-5-422-050

FHT-EX 105TTH Hand Cutting Torch Without consumables with 26.2 ft (8 m) cable/TCS13

EX-5-139-002

Starter Kit 75A For FHT-EX 105TTM Machine Torch

EX-5-433-052

FHT-EX 105TTM Machine Torch Without Gear Rack Without consumables, with 26.2 ft (8 m) cable/ TCS13

EX-5-204-031

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX