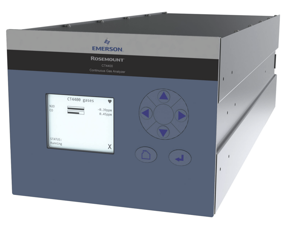

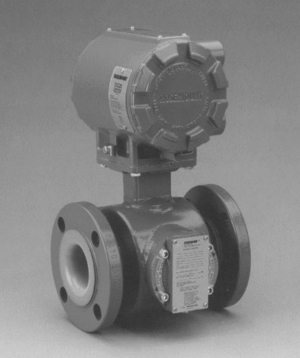

The Emerson pH/ORP Sensor 3900VP-02-10 is a high-performance industrial sensor designed for accurate pH and ORP measurements in various applications. Known for its reliability and durability, this sensor is essential for maintaining optimal process control in chemical and water treatment industries.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Emerson pH/ORP Sensor 3900VP-02-10

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Emerson pH/ORP Sensor 3900VP-02-10

Create an account to install this asset package.

Maintenance Plans for Emerson pH/ORP Sensor Model 3900VP-02-10

Integrate maintenance plans directly into your work orders in MaintainX.

pH Sensor Standardization

For maximum accuracy, you can standardize the sensor in-line or with a process grab sample after performing a buffer calibration and conditioning the sensor to the process. Standardization accounts for the sensor junction potential and other interferences. Standardization does not change the sensor's slope, but simply adjusts the transmitter's reading to match that of a known process pH

Procedure:

1. While obtaining a process solution sample, record the pH value that is shown on the transmitter display

Emerson recommends taking the sample close to the sensor

2. Measure and record the pH of the process solution sample with another temperature compensated and calibrated pH instrument

For best results, perform standardization at the process temperature

3. Adjust the transmitter to the standardized value;

Rosemount OPR Sensor Calibration

Prerequisites: Saturated quinhydrone ORP standard solution is available from Emerson (PN R508-8OZ) (460 ± 10 mV); You can also make ORP standard solution by adding a few crystals of quinhydrone to either a pH 4 or pH 7 buffer; Quinhydrone is only slightly soluble; therefore, only a few crystals are required

⚠ WARNING Corrosive substance The solution used during calibration is an acid; handle it with care Follow the directions of the acid manufacturer Wear the proper protective equipment Do not let the solution come into contact with skin or clothing If contact with skin is made, immediately rinse with clean water

Make a temporary electrical connection between the sensor and the transmitter to dissipate any accumulated electrical charge

Immerse the sensor in the standard solution; Allow one to two minutes for the ORP sensor to stabilize

Adjust the ORP value on the transmitter to the solution value shown in Table 4-1 The resulting potentials, measured with a clean platinum electrode and saturated KCl/AgCL reference electrode, should be within ±20 millivolts of the value shown in Table 4-1

Note solution temperature to ensure accurate interpretation of results; The ORP value of saturated quinhydrone solution is not stable over long periods of time; Therefore, make these standards fresh each time they are used

Sign off on the calibration procedure

pH/ORP Sensor Electrodes Cleaning

Erratic readings or sluggish response may indicate that the sensor is dirty and needs to be cleaned; The following are the recommended cleaning procedures for pH/ORP sensors

Procedure:

Clean the electrodes

To remove oil deposits, clean the electrodes with a mild, non-abrasive detergent

To remove scale deposits, soak the electrodes for one to five minutes in a five percent hydrochloric acid solution;

pH Sensor with Two Buffer Solutions Calibration

A two-point buffer calibration is the only way to ensure that a pH sensor is providing accurate measurements. During a two-point calibration, the transmitter calculates new values for slope (mV/pH) and zero offset (mV) based on the mV response of the sensor when it is in the pH standard solutions.

Procedure:

1. Immerse the sensor in the first buffer solution. Allow the sensor to adjust to the buffer temperature (to avoid errors due to temperature differences between the buffer solution and sensor temperature) and wait for readings to stabilize.

2. Once the transmitter has acknowledged the first buffer, rinse the buffer solution off the sensor by pouring a small amount of the second buffer solution over the tip of the sensor.

3. Repeat Step 1 using the second buffer solution.

Once the transmitter has acknowledged both buffer solutions, a sensor slope (mV/pH) is established.;

Parts for Emerson pH/ORP Sensor 3900VP-02-10

Access the parts list for your equipment in MaintainX.

Ball Valve Assembly

23240-00

1¼-in. NPT Ball Valve

9340078

Packing Rings

9160410

Ball Valve

934065

Retainer

33577-00

Ball Valve Assembly

23240-00

1¼-in. NPT Ball Valve

9340078

Packing Rings

9160410

Ball Valve

934065

Retainer

33577-00

Ball Valve Assembly

23240-00

1¼-in. NPT Ball Valve

9340078

Packing Rings

9160410

Ball Valve

934065

Retainer

33577-00

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX