Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

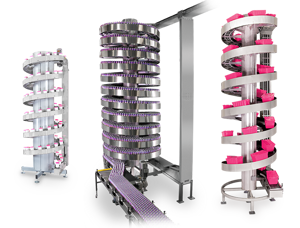

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Anderson Greenwood Spring Operated Pressure Relief Valve 81PS1F68-8

Create an account to install this asset package.

Maintenance Plans for Anderson Greenwood Spring Operated Pressure Relief Valve Model 81PS1F68-8

Integrate maintenance plans directly into your work orders in MaintainX.

Valve Adjustment

General

Two adjustments are provided on gas service valves, one for adjusting the opening pressure and one for adjusting the closing pressure

Set Pressure

Turn spring adjustment screw on bonnet in most of the way. Increase pressure to desired level and back out screw until valve pops

Lock screw with jam nut and retest

Readjust as required

Reseat Pressure

To adjust blowdown, turn blowdown adjustment screw IN to shorten blowdown; OUT to increase blowdown

Note

Valve Check

If the valve leaks after repair check the following!

1. Full and even seating of nozzle and guide

2. Foreign particles trapped between the seat and nozzle. If any are found they may have damaged the seat, making it necessary to replace it

3. Correct seat material for the valve set pressure.If items 1 and 2 reveal no evident seat leakage source, the procedures described in Section 5.2 may be used to eliminate seat leakage. Section 5.2 applies only to teflon seated -4, -6, or -8 orifice Series 81’s with nameplate set pressures that do not exceed 300 psig (2068 kpag);

Valve Repair

DISASSEMBLY!

1. Relieve spring tension and back blowdown adjusting screw out two turns

2. Remove inlet bushing, bushing seal and valve internals

3. Separate nozzle from guide by hitting top of spindle on soft surface

REPAIR!

1. Hold spindle by skirt O.D. in soft jaw vise and replace seat

2. Examine nozzle and polish out any scratches or nicks. Replace if necessary

3. To obtain better seat seal with PTFE at low set pressures, burnish seat against nozzle by chucking spindle in lathe and holding nozzle against spindle. Burnish with small force and for short time as PTFE readily deforms

ASSEMBLY!

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX