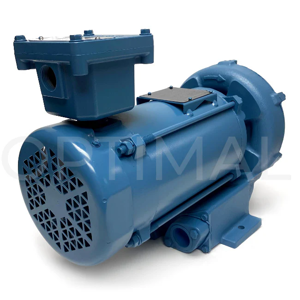

The Ametek Combustion Analyzer WDG-V OC8H is a sophisticated instrument designed for precise measurement and analysis of combustion processes. This advanced analyzer ensures optimal performance and compliance in industrial applications, providing reliable data for efficient energy management and emissions control.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Ametek Combustion Analyzer WDG-V OC8H

Create an account to install this asset package.

Maintenance Plans for Ametek Combustion Analyzer Model WDG-V OC8H

Integrate maintenance plans directly into your work orders in MaintainX.

Furnace Replacement

Analyzer opened and components exposed

Isolation valves on the inlet and outlet of the process closed

Cell furnace wires disconnected

Thermocouple assembly removed from the furnace

Cell removed

Flow Sensor removed

Swagelok nut at the bottom of the furnace loosened

Swagelok nut below the flow sensor loosened

Furnace assembly removed

Methane Detector Replacement

NOTE: The Combustibles Detector will always face outward, and the Methane detector will always face inward from the factory.

Heater Block removed

Methane Detector (Blue and White) wires disconnected on the Sensor board

Two (2) 4.0 mm hex screws that hold the Methane Detector loosened and detector removed from its housing

New o-ring used when the Methane Detector has been removed

New Methane detector installed in place, screws aligned on the block, and detector element ends not damaged while inserting the assembly

Block reinstalled

Detector leads reconnected to the Sensor board

Sign off on the Methane Detector Replacement

Thermocouple Replacement

Warning: The tip of the Thermocouple is positioned in the furnace so that it is near, but not touching, the Cell Housing or the furnace heater coil

Analyzer door opened

Isolation valves on the inlet and the outlet of the process closed

Thermocouple wires disconnected from terminals +C- on the Sensor board

Two (2) speed clips removed from the Thermocouple mounting tabs

Thermocouple removed from the furnace

New Thermocouple inserted aligning the tab with the two posts on the bottom plate

CAUTION: Take care to avoid damaging the ceramic tip while inserting the assembly

One new speed nut attached to each post

Sensor Board Replacement

Disconnect all wires

Loosen the two Phillips screw located on the back of the electronics plate

Slide the board out until the pegs at the top line up with the holes in the Sensor board plate and drop it down

Replace the Sensor board

Properly tighten the screws

Sign off on the Sensor Board Replacement

Block Heater Replacement

Warning: Only perform this procedure on Combustibles/Methane Units

Disconnect heater wires

Loosen the 4.0 mm hex screw

Remove the Combustibles Block Heater by sliding it out

Replace the Block Heater

Tighten the hex screw into place

Reconnect the wires on the Sensor board

Sign off on the block heater replacement

Parts for Ametek Combustion Analyzer WDG-V OC8H

Access the parts list for your equipment in MaintainX.

Analyzer Main Processor Board

8000-148-SE

Kit

7000-840-TE

Kit

7000-848-TE

Kit

7000-817-TE

Cell O-Ring

42005JE

Analyzer Main Processor Board

8000-148-SE

Kit

7000-840-TE

Kit

7000-848-TE

Kit

7000-817-TE

Cell O-Ring

42005JE

Analyzer Main Processor Board

8000-148-SE

Kit

7000-840-TE

Kit

7000-848-TE

Kit

7000-817-TE

Cell O-Ring

42005JE

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX