Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

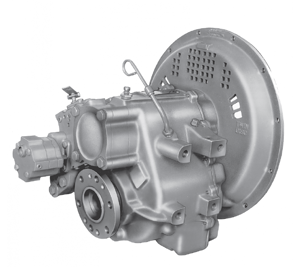

Twin Disc Marine Transmission MGX-5095SC

Create an account to install this asset package.

Maintenance Plans for Twin Disc Marine Transmission Model MGX-5095SC

Integrate maintenance plans directly into your work orders in MaintainX.

100 Hourly Safety Valve Lubrication

Lubrication

Is your unit equipped with a lubrication fitting?

Upload a photo of the lubrication fitting

Enter the current hours on the transmission output shaft

Apply grease approximately every 100 hours when boat is docked

Select the type of grease used

Enter the NLGI consistency number for the grease used

Sign off on the lubrication procedure

1000 Hourly Rebuilt Transmission Filter and Oil Change

Look for lint or other material that may collect from rags or towels used in the parts cleaning process.

Look for chips or shavings particularly if the transmission has had a problem that caused debris in the system. (For units with spin-on filters, this will require cutting the filter element apart to access the element core.); If the filter is clean, install a new filter element and then change the oil and filter element after 1000 hours of service. If the filter is dirty, change the element and operate for another eight hours. Check the filter again.

Continue this cycle until the filter is clean and then change the oil and filter after 1000 hours of service, or more often if conditions warrant.

NOTE: Situations involving debris in the hydraulic system will require that heat exchangers and all connecting lines and hoses be thoroughly cleaned. If the heat exchanger cannot be disassembled, or if it cannot be assured that all debris is removed, the heat exchanger should be replaced.

F. Suction Strainer

Remove and clean the suction strainer at every oil change or sooner if necessary. See illustrations in Section 6.2 for the location of the suction strainer for your transmission.

Draining

Drain the transmission by removing the oil drain plug from the rear/bottom of the transmission. See the illustrations in Section 6.2 or service literature for your transmission for location of transmission and filter drain plugs.

NOTE: Dispose of used oil and oil filters in accordance with federal, state or local laws. Exercise precautions to prevent environmental contamination during any transmission servicing procedure.

4 Weekly Heat Exchanger Check

Warning: This check requires trained personnel with PPE!

Heat exchangers have anodes installed at the inlet and outlet heads

Enter the percentage of the rod disintegrated

Is over one half of the rod disintegrated?

If over one half of the rod is disintegrated, replace it to assure effective protection.

Excessive corrosion of the anode indicates electrolytic action

Make a careful inspection to determine if this action is caused by a short circuit or an external grounded electric current.

Is the action caused by a short circuit or an external grounded electric current?

If either of these conditions is found, do what is required to correct it to avoid frequent replacement of the anodes.

2000 Hourly / 6 Monthly Flexible Input Coupling Inspection

Warning: Do not obstruct the flywheel housing vents

Is the ambient temperature of the air around the coupling within the operating range (-6°C to 82°C)?

Enter the current operating hours of the machine

If possible, visually inspect the coupling after the first 100 hours of operation, and every 2000 hours thereafter, or every six months, whichever comes first.

Any signs of torsional vibration, misalignment, degradation by contaminants (oil), heat, ultraviolet radiation, and excessive system torque on the coupling?

If coupling access is restricted, inspection may be possible only at engine overhaul or whenever the transmission is separated from the engine.

Any accumulation of residue at the flywheel housing vents?

If an accumulation of residue is found, describe the possible cause.

Sign off on the inspection

Initial 50 Hours New Transmission Filter and Oil Change

With a new transmission, change the oil and filter element within first 50 hours of operation. Change the oil more frequently if conditions warrant.

F. Suction Strainer

Remove and clean the suction strainer at every oil change or sooner if necessary. See illustrations in Section 6.2 for the location of the suction strainer for your transmission.

Draining

Drain the transmission by removing the oil drain plug from the rear/bottom of the transmission. See the illustrations in Section 6.2 or service literature for your transmission for location of transmission and filter drain plugs.

NOTE: Dispose of used oil and oil filters in accordance with federal, state or local laws. Exercise precautions to prevent environmental contamination during any transmission servicing procedure.

Filling

1. Remove the breather or the oil fill closure from the top of transmission case.

2. Pour new oil through breather or closure opening. Fill with recommended clean oil, taking necessary precautions to prevent entry of dirt or debris. (See lubrication plate on transmission and information transcribed to the front of this manual for additional oil information.);

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX