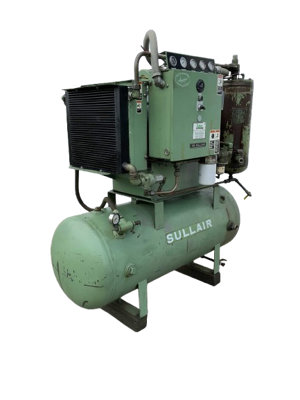

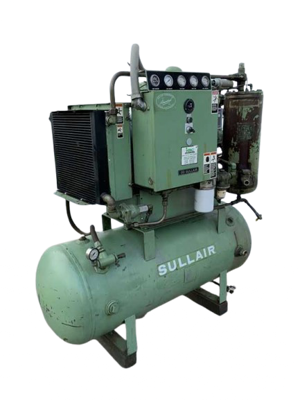

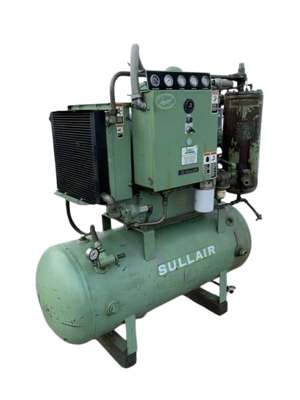

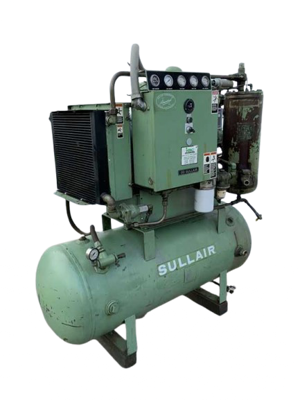

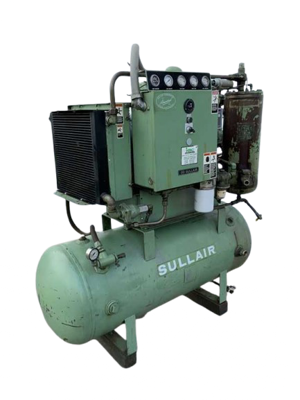

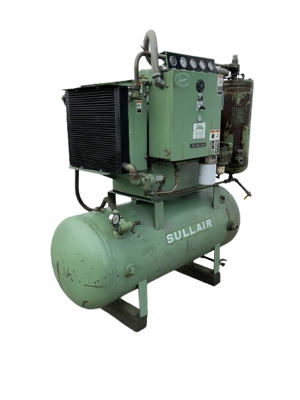

The Sullair Industrial Air Compressor 1810 is a robust and efficient solution for various industrial applications. Known for its reliability and performance, this compressor is designed to deliver consistent air pressure while minimizing downtime through effective maintenance strategies. Ideal for demanding environments, it ensures optimal productivity and operational efficiency.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Sullair Industrial Air Compressor 1810

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Sullair Industrial Air Compressor 1810

Create an account to install this asset package.

Maintenance Plans for Sullair Industrial Air Compressor Model 1810

Integrate maintenance plans directly into your work orders in MaintainX.

2000 Hourly Fluid Filter Replacement

Replace your fluid filter element under any of the following conditions, whichever occurs first:

1. As indicated by the WS Controller.

2. Every fluid change.

Fluid Filter Element Replacement

1. Using a wrench, remove the filter canister.

2. Remove and dispose of filter element. Observe all laws and regulations for filter disposal.

3. Clean gasket seating surface.

4. Apply a light film of fluid to the element seal.

5. Install the element into the filter canister.

1 Yearly Air Filter Replacement

Maintenance indicator shows red with the compressor running full load?

If the filter needs to be replaced, order a replacement element.

Clean exterior of air filter housing.

Rotate end cover counterclockwise and remove.

Remove air filter element by pulling it out of the housing.

Clean interior of housing using a damp cloth. DO NOT blow dirt out with compressed air.

At this time replace the element.

Reassemble in the reverse order of the disassembly.

Sign off on the air filter replacement

1 Daily Compressor Inspection

Warning: HIGH-PRESSURE HAZARD! DO NOT remove caps, plugs, and/or other components when compressor is running or pressurized. Stop compressor and relieve all internal pressure before doing so. Failure to comply could result in death or serious injury.

Fluid level in the separator/sump tank is sufficient

If fluid level is low, note down the amount of fluid added

If the addition of fluid becomes too frequent, a simple problem has developed which is causing this excessive loss. See the Section 6.9: Troubleshooting—Introduction on page 61 under EXCESSIVE COMPRESSOR FLUID CONSUMPTION for a probable cause and remedy.

Controller display monitors the correct readings for their particular phase of operation

Compressor is running properly after warming up

Sign off on the daily compressor inspection

2000 Hourly Fluid Return/Sight Glass Maintenance

Warning: This maintenance requires trained personnel with PPE!

Disconnect the tube at the bottom of the sight glass.

Unscrew the sight glass assembly where the elbow fitting joins the strainer/filter.

Upload a photo of the used filter assembly.

Remove used filter assembly, and replace with new assembly.

Inspect and clean the orifice inside the sight glass blocks. The orifice must be removed with an Allen wrench.

Coat/lubricate the O-rings with silicone grease.

Reattach the connectors to the sight glass/orifice blocks.

Sign off on the fluid return/sight glass maintenance.

1 Yearly Separator Replacement

Warning: Relieve all pressure from the separator/sump tank and all compressor lines.

Loosen and remove the six (6) hex head cap screws (8.8 M12 x 40 mm) from the cover plate.

Lift the cover plate from the separator/sump tank.

Remove the separator element.

Inspect the separator/sump tank for rust, dirt, etc.

Reinsert the separator element into the separator/sump tank taking care not to dent the element against the tank opening.

Install a new O-ring in the O-ring groove on the underside of the separator/sump tank cover.

Replace the cover plate, washers and cap screws. Torque to 70 ft·lbs (95 N·m).

Clean the return line strainer before restart.

Parts for Sullair Industrial Air Compressor 1810

Access the parts list for your equipment in MaintainX.

Tank, Separator 2200

02250155-599

Plug, Sight Glass 1 5/16” SAE

02250097-610

Filter, Air 8” (Plastic) W/MTG Band

02250125-369

Strainer, V-Type 300PSIX1/4

241771

Gauge, Differential Pressure Z-PRG Assembly Bottom

02250169-612

Tank, Separator 2200

02250155-599

Plug, Sight Glass 1 5/16” SAE

02250097-610

Filter, Air 8” (Plastic) W/MTG Band

02250125-369

Strainer, V-Type 300PSIX1/4

241771

Gauge, Differential Pressure Z-PRG Assembly Bottom

02250169-612

Tank, Separator 2200

02250155-599

Plug, Sight Glass 1 5/16” SAE

02250097-610

Filter, Air 8” (Plastic) W/MTG Band

02250125-369

Strainer, V-Type 300PSIX1/4

241771

Gauge, Differential Pressure Z-PRG Assembly Bottom

02250169-612

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX