Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

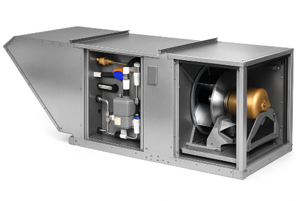

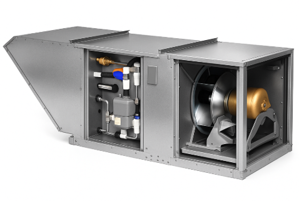

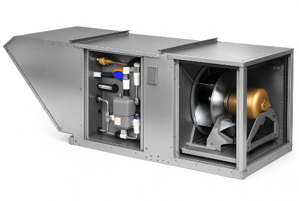

Sullair Compressor 16B-60

Create an account to install this asset package.

Maintenance Plans for Sullair Compressor Model 16B-60

Integrate maintenance plans directly into your work orders in MaintainX.

Compressor Maintenance

PARTS REPLACEMENT AND ADJUSTMENT PROCEDURES

FLUID FILTER ELEMENT REPLACEMENT

1. Using a strap wrench, remove the old element and gasket.

2. Clean gasket seating surface.

3. Apply a light film of fluid to the new gasket.

4. Hand tighten new element until new gasket is seated in the gasket groove. Avoid any nick, cuts or pinches to the gasket.

5. Continue tightening element by hand an additional 1/2 to 1/4 turn.

6. Restart compressor and check for leaks.

AIR FILTER ELEMENT REPLACEMENT

Initial 50 Hours Compressor Maintenance

Warning: Ensure the compressor is turned off and cooled down before performing any maintenance tasks.

Clean the return line strainer.

Clean the return line orifice.

Clean the compressor unit gear housing.

Clean the bearing and shaft seal orifices.

Note: Care must be taken not to damage shaft seal.

Sign off on the maintenance tasks.

1000 Hourly Compressor Maintenance

Clean the return line strainer

Lubricate the Sullicon Control linkage

Replace the fluid filter element and gasket

STANDARD COMPRESSORS ONLY!

Drain the sump and change the compressor fluid

Sign off on the 1000 hourly compressor maintenance

6 Monthly / 1000 Hourly Filter Maintenance

Filter Maintenance Guide

Replace your fluid filter element and the gasket under any of the following conditions, whichever occurs first:

Filter Replacement Conditions

Was the filter replaced successfully?

Sign off on the filter maintenance

1 Daily Compressor Maintenance

Before starting the compressor, check the fluid level in the sump.

Enter the fluid level in the sump

Is the fluid level low?

If the fluid level is low, add the necessary amount.

If the addition of fluid becomes too frequent, a problem has developed causing this excessive loss.

After a routine start, observe the instrument panel gauges.

Do the gauges monitor the correct readings for that particular phase of operation?

After the compressor has warmed up, perform a general check on the overall compressor and instrument panel.

Is the compressor running properly?

Parts for Sullair Compressor 16B-60

Access the parts list for your equipment in MaintainX.

Element For Compressor Fluid Filter 250025-522

250025-526

Element For Standard Air Filter 250020-315

40899

Element For Heavy Duty Primary Air Filter 47274 (16 Series)

47542

Element For Heavy Duty Safety Air Filter 47274

47543

Primary Element For Separator 250034-117 (16 Series

250034-118

Element For Compressor Fluid Filter 250025-522

250025-526

Element For Standard Air Filter 250020-315

40899

Element For Heavy Duty Primary Air Filter 47274 (16 Series)

47542

Element For Heavy Duty Safety Air Filter 47274

47543

Primary Element For Separator 250034-117 (16 Series

250034-118

Element For Compressor Fluid Filter 250025-522

250025-526

Element For Standard Air Filter 250020-315

40899

Element For Heavy Duty Primary Air Filter 47274 (16 Series)

47542

Element For Heavy Duty Safety Air Filter 47274

47543

Primary Element For Separator 250034-117 (16 Series

250034-118

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX