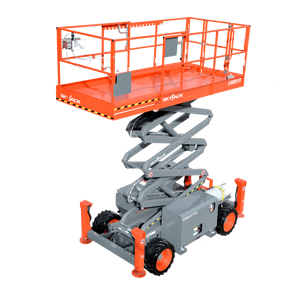

The Skyjack Telescopic Boom SJ82 T is a versatile aerial work platform designed for maximum reach and stability. This robust equipment is ideal for construction and maintenance tasks, providing reliable performance and safety features for operators in various industrial applications.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Skyjack Telescopic Boom SJ82 T

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Skyjack Telescopic Boom SJ82 T

Create an account to install this asset package.

Maintenance Plans for Skyjack Telescopic Boom Model SJ82 T

Integrate maintenance plans directly into your work orders in MaintainX.

Platform Level Relief Valve Adjustment

Locate the GP2 port on the main manifold

Connect a pressure gauge (5000 psi) to the GP2 port

Start the engine from the base control console and let it run for 2-5 minutes

Raise the main boom to ensure the basket will not contact the ground

Fully raise or lower the platform level and check the reading on the gauge

Is the pressure 3000 psi?

Locate the platform leveling relief valve RV3

Loosen the lock nut on the platform level relief valve RV3

Turn the adjusting stem

1 Yearly Filter Replacement

Place a suitable container under the hydraulic tank filter

Remove the oil filter and catch any escaping oil

WARNING! Dispose of hydraulic oil in accordance with local and federal regulations

Clean inside the filter head

Apply a thin layer of clean hydraulic oil to the new oil filter gasket

Install the filter and tighten it firmly

Clean up any oil that may have spilled during this procedure

Start the engine from the base control console

Check for leakage

Torque Hub Oil Replacement

Engine started and boom driven until fill/drain port is in 6 o'clock position

Engine shut off and container placed under fill/drain port

Plug removed and oil drained without spills

Engine restarted and boom driven until drain plug is in 3 or 9 o'clock position

Engine shut off

Amount of new oil filled in hub as per specifications

Above steps repeated with other three wheel hubs

Sign off on the torque hub oil replacement

Telescopic Boom Greasing

Warning: Ensure the machine is turned off and secured before starting the procedure

Apply open gear lube to each tooth of the swing drive gear, located under the turret

Open the axle cover plates and locate the grease fittings

Pump grease into the grease fittings

Locate the grease fittings on the drive shaft u-joints, and pump grease into the fittings

Sign off on the telescopic boom greasing

Reverse Drive Pressure on Drive Pump Testing

NOTE! Make sure the charge pump pressure test is completed first

Locate test port TP2 on the drive pump

Connect a pressure gauge (10000 psi) to test port TP2

WARNING! To protect the gauge, do not activate any controls during this procedure

Start the engine from the platform control console

Unplug the brake solenoid power cable on the brake valve

Activate the drive function slowly in reverse with the engine at high speed. The wheels should not turn

NOTE! Activating the drive function too quickly will stall the engine

Reading on the gauge

Parts for Skyjack Telescopic Boom SJ82 T

Access the parts list for your equipment in MaintainX.

Light, Green (Low Capacity) (Platform Control Console)

170501

Light, Green (High Capacity) (Base Control Console)

170501

Light, Amber (Low Fuel) (Base Control Console)

170502

Light, Amber (Load Zone Border) (Base Control Console)

170502

Light, Amber (Differential Lock) (Platform Control Console)

171502

Light, Green (Low Capacity) (Platform Control Console)

170501

Light, Green (High Capacity) (Base Control Console)

170501

Light, Amber (Low Fuel) (Base Control Console)

170502

Light, Amber (Load Zone Border) (Base Control Console)

170502

Light, Amber (Differential Lock) (Platform Control Console)

171502

Light, Green (Low Capacity) (Platform Control Console)

170501

Light, Green (High Capacity) (Base Control Console)

170501

Light, Amber (Low Fuel) (Base Control Console)

170502

Light, Amber (Load Zone Border) (Base Control Console)

170502

Light, Amber (Differential Lock) (Platform Control Console)

171502

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX