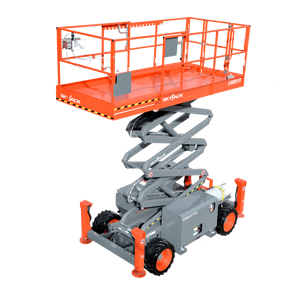

The Skyjack Rough Terrain Scissors SJ9243 RT is a robust and versatile aerial work platform designed for outdoor applications. With its exceptional lifting capabilities and durable construction, this model ensures safety and efficiency in various industrial tasks. Ideal for construction and maintenance projects, it offers reliable performance in challenging environments.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Skyjack Rough Terrain Scissors SJ9243 RT

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Skyjack Rough Terrain Scissors SJ9243 RT

Create an account to install this asset package.

Maintenance Plans for Skyjack Rough Terrain Scissors Model SJ9243 RT

Integrate maintenance plans directly into your work orders in MaintainX.

200 Daily / 200 Hourly Lifting Mechanism - Mast/Scissors Maintenance

Maintenance Support(s) correctly attached & no damage

Scissor Assembly & Bumpers correctly attached, no deformation/damage

Cables & wires installed with no damage

Sliders & Rollers correctly attached & no obstructions, dirt, or damage/wear

Lift Cylinder(s) have no damage or missing components, tight fittings and hoses & no leaks, correctly installed

Height Sensor correctly attached & no damage

Scissor Pins correctly attached & no damage

Mast Assembly has no damage, cracks, or deformation

Mast Assembly lubricated as recommended

200 Daily / 200 Hourly DC Electrical Scissors Inspection

No open service bulletins

Annual inspection completed within 13 months

Labels in place, correctly attached & readable

Limit switches correctly installed & no obstructions or damage

Manifolds have tight fittings and hoses & no damage or leaks

Manifolds have tight wire connections, no missing components & correctly working valves

Main Power Disconnect Switch cables are tight & in working order

Base Controls operate switches and they all operate correctly

Base Controls have no damage or missing components

200 Daily / 200 Hourly Platform Maintenance

Railings and Gate: Correctly attached & no damage or missing components

Fall-Protection Anchorage: Attachment rings correctly attached & no damage

AC Power Socket: No obstructions, dirt, or damage

Platform Control Console: Operate the switches and make sure they all operate correctly. No damage or missing components

Upload a photo of the Platform Control Console

Manual Storage Box: Manuals and documents are in the storage box, in good condition, and you can read them

Powered Extension Control Console: Operate switches and make sure they all operate correctly. No damage or missing components

Upload a photo of the Powered Extension Control Console

Extension Platform: Correctly attached & no damage or missing components

200 Daily / 200 Hourly Base/Engine Maintenance

Engine and Components check

Engine Intake Air Filter check

Engine Oil level

Radiator check

Fuel Tank & Lines check

Propane Tank & Lines check

Outriggers check

Pothole Protection check

Battery/Hydraulic Tray check

1 Yearly Base/Engine Maintenance

Engine oil and filter replaced

Air filter replaced if necessary

Coolant level & condition checked and replaced if necessary

Wheel nuts torqued as recommended

Axle oil checked and replaced if necessary

Hydraulic oil and filters checked and replaced if necessary

Under normal use and operating conditions, you should change the hydraulic oil every two years.

Sign off on the maintenance

Parts for Skyjack Rough Terrain Scissors SJ9243 RT

Access the parts list for your equipment in MaintainX.

Valve, Pressure Dump

229291

Valve, Drive Reverse

213997

Valve, Lower

229303

Valve, Generator

158058

Valve, Lift

246029

Valve, Pressure Dump

229291

Valve, Drive Reverse

213997

Valve, Lower

229303

Valve, Generator

158058

Valve, Lift

246029

Valve, Pressure Dump

229291

Valve, Drive Reverse

213997

Valve, Lower

229303

Valve, Generator

158058

Valve, Lift

246029

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX