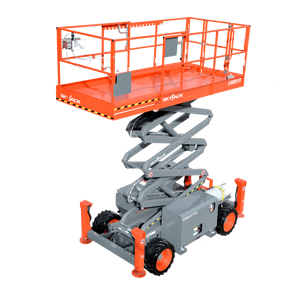

The Skyjack Telescopic Boom SJ66 T+ is a versatile aerial work platform designed for maximum reach and stability. This robust equipment is ideal for construction and maintenance tasks, offering exceptional maneuverability and safety features for operators. Experience enhanced productivity with the SJ66 T+, a reliable choice for heavy-duty lifting applications.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Skyjack Telescopic Boom SJ66 T+

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Skyjack Telescopic Boom SJ66 T+

Create an account to install this asset package.

Maintenance Plans for Skyjack Telescopic Boom Model SJ66 T+

Integrate maintenance plans directly into your work orders in MaintainX.

Fuel Filter Replacement

Remove the bolt securing the engine tray to the turret

Pull the locking pin down and swing the engine tray away from the turret

Close the fuel shut-off valve

Place a suitable container under the fuel filter

Remove the fuel filter and catch any escaping fuel

WARNING! Dispose of fuel in accordance with local and federal regulations

Clean any dirt from the filter carrier sealing surface

Apply a thin layer of oil or diesel fuel to the rubber gasket of the new fuel filter

Install the fuel filter and tighten it by hand, then tighten the filter cartridge with a final half-turn

Platform Level Relief Valve Adjustment

Locate the GP2 port on the main manifold

Connect a pressure gauge (5000 psi) to the GP2 port

Start the engine from the base control console and let it run for 2-5 minutes

Raise the main boom to ensure the basket will not contact the ground

Fully raise or lower the platform level and check the reading on the gauge

Is the pressure 3000 psi?

Locate the platform leveling relief valve RV3

Loosen the lock nut on the platform level relief valve RV3. Turn the adjusting stem clockwise to increase the pressure and counterclockwise to decrease the pressure

Tighten the lock nut on the platform level relief valve RV3 once 3000 psi is observed on the gauge. You must fully raise or lower the platform level to activate a pressure reading on the gauge

Reverse Drive Pressure on Drive Pump Testing

NOTE! Make sure the charge pump pressure test is completed first

Locate test port TP2 on the drive pump

Connect a pressure gauge (10000 psi) to test port TP2

WARNING! To protect the gauge, do not activate any controls during this procedure

Start the engine from the platform control console

Unplug the brake solenoid power cable on the brake valve

Activate the drive function slowly in reverse with the engine at high speed. The wheels should not turn

NOTE! Activating the drive function too quickly will stall the engine

Reading on the gauge

Oscillating Cylinder Bolt Replacement

Check if the oscillating cylinder bolts have missing or damaged torque seal

If more than one bolt is replaced, do so one at a time to prevent the cylinder from shifting

Remove the affected bolt

Clean the cylinder’s corresponding internal threaded hole thoroughly

Choose the type of bolt used for replacement

Hand-tighten the bolt

Enter the torque applied to the new bolt

Apply a line of torque seal to each new bolt extending from the bolt head over the washer and to the chassis wall

Sign off on the bolt replacement

1 Yearly Oil Sample Testing

Warning: Only trained personnel should perform this procedure

Oil sample drawn from the reservoir

Oil sample taken when oil is warmed through normal operation

Upload the oil sample test results

Enter the name of the lubrication specialist

Oil sample suitable for continued use

Sign off on the oil sample testing

Parts for Skyjack Telescopic Boom SJ66 T+

Access the parts list for your equipment in MaintainX.

Cylinder (Boom Lift)

230130

Valve, Control (Pressure Dump)

103656

Cylinder (Axle Lock)

212871

Valve, Counterbalance (Jib)

149488

Valve, Control (Boom Down)

166052

Cylinder (Boom Lift)

230130

Valve, Control (Pressure Dump)

103656

Cylinder (Axle Lock)

212871

Valve, Counterbalance (Jib)

149488

Valve, Control (Boom Down)

166052

Cylinder (Boom Lift)

230130

Valve, Control (Pressure Dump)

103656

Cylinder (Axle Lock)

212871

Valve, Counterbalance (Jib)

149488

Valve, Control (Boom Down)

166052

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX