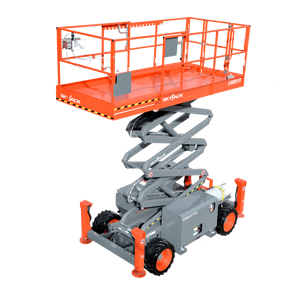

The Skyjack Telescopic Boom SJ61 T+ is a versatile aerial work platform designed for maximum reach and efficiency. With its robust construction and advanced safety features, this model is ideal for various industrial applications, ensuring reliable performance and operator safety in challenging environments.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Skyjack Telescopic Boom SJ61 T+

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Skyjack Telescopic Boom SJ61 T+

Create an account to install this asset package.

Maintenance Plans for Skyjack Telescopic Boom Model SJ61 T+

Integrate maintenance plans directly into your work orders in MaintainX.

Charge Pump Pressure on Drive Pump Testing

Locate test port TP3 on the drive pump

Connect a pressure gauge (600 psi) to the test port

Start the engine from the base control console

WARNING! To protect the gauge, do not activate any controls during this procedure

Check the reading on the gauge. Standard pressure should be 313 ±31 psi

Is the standard pressure achieved?

Replace the charge pump relief valve RV10 4 if the standard pressure is not achieved

Repeat steps 2, 3, and 4 after the charge pump relief valve is replaced

Is the pressure in range after replacing the charge pump relief valve?

200 Hourly Telescopic Boom Service

Check Planetary reduction oil level

Tighten Gear box screws/bolts

Tighten Wheel Nuts

Replace differential oil every 800 Hours

Replace planetary reduction oil every 1000 Hours

Replace Self-locking differential gear oil every 700 Hours

Replace Gear box oil once at 50 Hours after every 1000 Hours

Sign off on the 200 Hourly Telescopic Boom Service

Hydraulic Brake Pressure Adjustment

Warning: This procedure requires trained personnel with PPE!

Locate the pressure gauge on the brake valve assembly

IMPORTANT! Failure to remove the wiring may cause damage to components downstream

Remove the wiring from two valves: axle lockout valve wires 65 and 02, and two speed valve wires 45 and 02. Mark the valves to ensure you put the wiring back in the correct positions later

IMPORTANT Valve damage will occur if tightened too much

Locate the brake system pressure reducing valve PR1 4 . Loosen the lock nut and turn the adjustment stem gently clockwise 2 full turns

Start the engine from the platform control console and extend the boom slightly (approximately 12” (30 cm)) to achieve low speed drive

Drive the MEWP forward or reverse. The pressure gauge reading should be 400 psi. Stop the aerial platform. Follow the next steps for adjusting the relief valve pressure if needed. If no adjustment is required

Locate the brake system pressure reducing valve PR1 and turn the valve gently counterclockwise to the initial position

Oil Level in the Torque Hubs Check

Drive the MEWP to rotate the hub until the plug is in the 3 or 9 o’clock position. Shut off the engine.

Remove the plug and check the oil level. The oil level should be even with the bottom of the plug hole.

Add oil if needed.

Telescopic Boom Greasing

Warning: This procedure requires trained personnel with PPE!

Control side cowling opened

Turret ring gear grease fitting located beside the hydraulic tank

Grease pumped into the fitting until new lube appears continuously around the grease seal lip of the ring gear

Turret rotated in increments of 10 to 13 cm (4 to 5 inches) at a time

Entire bearing greased

Open gear lube applied to each tooth of the swing drive gear, located under the turret

Axle cover plates opened and grease fittings located

Grease pumped into the axle grease fittings

Parts for Skyjack Telescopic Boom SJ61 T+

Access the parts list for your equipment in MaintainX.

Valve, Control (Flow Enable, 12kW Generator)

168058

Valve, Control (Flow Enable)

166050

Valve, Control (Axle Lock Out)

159827

Valve, Control (Load Circuit)

194492

Valve, Counterbalance (Platform Level)

166772

Valve, Control (Flow Enable, 12kW Generator)

168058

Valve, Control (Flow Enable)

166050

Valve, Control (Axle Lock Out)

159827

Valve, Control (Load Circuit)

194492

Valve, Counterbalance (Platform Level)

166772

Valve, Control (Flow Enable, 12kW Generator)

168058

Valve, Control (Flow Enable)

166050

Valve, Control (Axle Lock Out)

159827

Valve, Control (Load Circuit)

194492

Valve, Counterbalance (Platform Level)

166772

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX