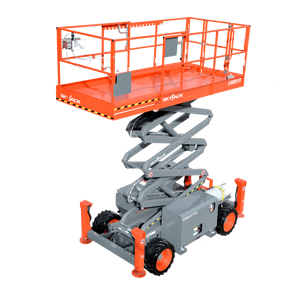

The Skyjack Telescopic Boom SJ 86T is a versatile and robust aerial work platform designed for high-reach applications. Known for its reliability and ease of use, this model features advanced hydraulic systems and safety mechanisms, making it ideal for construction and maintenance tasks. Experience exceptional performance with the SJ 86T from Skyjack.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Skyjack Telescopic Boom SJ 86T

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Skyjack Telescopic Boom SJ 86T

Create an account to install this asset package.

Maintenance Plans for Skyjack Telescopic Boom Model SJ 86T

Integrate maintenance plans directly into your work orders in MaintainX.

Oscillating Axle Cylinders Testing

Extend the fly boom 1 ft (30) cm while on a firm, level surface

The steer axle should be locked

Drive one of the steer tires up onto a 6” (15 cm) block or curb

An appropriate tilt of the MEWP chassis should occur

Retract the fly boom while in tilt position

The steer axles should unlock and the MEWP chassis should level itself to the ground

Sign off on the Oscillating Axle Cylinders Testing

Oil Cooler Check

Remove the cover from the side of the engine

Inspect the oil cooler for leaks and physical damage

Clean the oil cooler of any kind of debris

Reinstall the cover

Charge Pump Pressure on Drive Pump Testing

Locate test port TP3 on the drive pump

Connect a pressure gauge (600 psi) to the test port

Start the engine from the base control console

WARNING! To protect the gauge, do not activate any controls during this procedure

Check the reading on the gauge. Standard pressure should be 313 ±31 psi

Is the standard pressure achieved?

Replace the charge pump relief valve RV10 4 if the standard pressure is not achieved

Repeat steps 2, 3, and 4 after the charge pump relief valve is replaced

Is the pressure in range after replacing the valve?

Engine Belt Check

Warning: Do not inspect the fan belt while the engine is running. Remove the key to prevent accidental operation

Engine belt for cracking

Engine belt for glazing

Engine belt for separation

Engine belt for breaks

For correct tension of the engine belt, refer to the engine manual

Sign off on the engine belt check

Platform Level Relief Valve Adjustment

Locate the GP2 port on the main manifold

Connect a pressure gauge (5000 psi) to the GP2 port

Start the engine from the base control console and let it run for 2-5 minutes

Raise the main boom to ensure the basket will not contact the ground

Fully raise or lower the platform level and check the reading on the gauge

Is the pressure 3000 psi?

Locate the platform leveling relief valve RV3

Loosen the lock nut on the platform level relief valve RV3

Turn the adjusting stem clockwise to increase the pressure and counterclockwise to decrease the pressure

Parts for Skyjack Telescopic Boom SJ 86T

Access the parts list for your equipment in MaintainX.

Valve, Control - Pressure Dump

159805

Valve, Control - Platform Level Up

159803

Valve, Control - Axle Lock Out

159827

Cylinder, Boom Lift

165079

Cylinder, Boom Extend

165080

Valve, Control - Pressure Dump

159805

Valve, Control - Platform Level Up

159803

Valve, Control - Axle Lock Out

159827

Cylinder, Boom Lift

165079

Cylinder, Boom Extend

165080

Valve, Control - Pressure Dump

159805

Valve, Control - Platform Level Up

159803

Valve, Control - Axle Lock Out

159827

Cylinder, Boom Lift

165079

Cylinder, Boom Extend

165080

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX