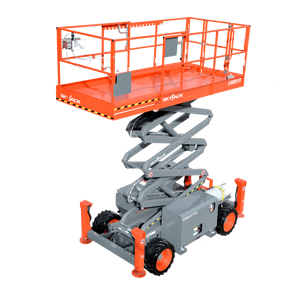

The Skyjack Telehandlers ZB2044 is a versatile and robust piece of industrial equipment designed for lifting and moving materials in construction and warehousing environments. Known for its reliability and ease of use, this telehandler model offers exceptional performance and maneuverability, making it a preferred choice for operators.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Skyjack Telehandlers ZB2044

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Skyjack Telehandlers ZB2044

Create an account to install this asset package.

Maintenance Plans for Skyjack Telehandlers Model ZB2044

Integrate maintenance plans directly into your work orders in MaintainX.

1 Weekly / 40 Hourly Boom Inspection

Check Slide Pads:

1. With telehandler parked on a level surface and park brake applied, remove access door at rear of boom.

2. Measure slide pad thickness (top and bottom of each boom section) inside rear of boom.

3. Raise boom slightly and extend boom approximately 6’ (2M). Measure slide pad thickness (top, bottom, and sides of each boom section) at front end of boom.

4. Replace any pads that are less than 3/4” (19mm) thick.

5. Shim all slide pads as required (more than 1/8” or 3mm gap).

5.4-4 Replacing and Shimming Slide Pads:: 1. With machine parked on a level surface and park brake applied, remove access door at rear of boom.

2. Remove grease fittings and bolts of slide pads to be shimmed/replaced. (Do not use heat.)

3. Add shims as required to obtain 0-1/16” (0-1.5mm) clearance with no drag.

1 Daily Telehandlers Inspection

All labels are in place and are legible

Proper operation of all gauges

Check charging system Ammeter/Voltmeter

Inspect boom wiring harnesses for chafed, corroded and loose wires

Inspect frame wiring harnesses for chafed, corroded and loose wires

Inspect cab wiring harnesses for chafed, corroded and loose wires

Ensure electrical devices are properly secured with no signs of visible damage

Ensure there are no loose or missing parts

Ensure safety switches are properly secured with no signs of visible damage

1 Yearly / 1000 Hourly Hydraulic Oil Replacement

Change Hydraulic Oil

Is the telehandler on a firm level surface and in a stowed position?

Has the hydraulic oil been warmed up?

Is the engine turned off?

Upload a photo of the suitable container placed under the hydraulic tank.

Has the oil drain plug been removed and all hydraulic oil drained into the container?

Has the oil drain plug been installed with a new seal ring and tightened firmly?

Enter the amount of new oil refilled into the hydraulic tank as per specifications.

Any leakage detected?

1 Daily Boom Inspection

Ensure there are no loose or missing parts and there is no visible damage.

Ensure all bolts and pins are properly tightened.

Ensure there are no visible cracks in welds or structure and there are no signs of deformation.

Ensure all hoses are properly tightened and there is no evidence of hydraulic leakage.

Chain: Ensure there are no loose or missing parts and there is no visible damage.

Boom Angle Indicator: Ensure all bolts are tight, and there is no visible damage.

Inspect Proximity Sensor.

Lifting Attachment: Ensure there are no loose or missing parts and there is no visible damage.

- Ensure attachment is properly positioned and secured. (Refer to Section 2.13 of the operating manual for attachments.)

1 Yearly / 1000 Hourly Drive Axles Oil Replacement

Ensure telehandler is on a firm level surface and is in stowed position.

Engine turned off

Place a suitable container under the axle.

Fill plug removed

Drain plug removed to allow oil to drain into the container.

All drain plugs reinstalled

Check plug removed

Refill axle with new oil as per specifications (refer to Table 2.2).

Axle is filled when oil is leaking from the check port.

Parts for Skyjack Telehandlers ZB2044

Access the parts list for your equipment in MaintainX.

Accumulator, Brake Charge

400947

Accumulator, Joystick

400947

Cylinder, Boom Lift

401061

Cylinder, Boom Extension

409301

Cylinder, Front Steer (RH) (Part of Axle Assembly)

409321

Accumulator, Brake Charge

400947

Accumulator, Joystick

400947

Cylinder, Boom Lift

401061

Cylinder, Boom Extension

409301

Cylinder, Front Steer (RH) (Part of Axle Assembly)

409321

Accumulator, Brake Charge

400947

Accumulator, Joystick

400947

Cylinder, Boom Lift

401061

Cylinder, Boom Extension

409301

Cylinder, Front Steer (RH) (Part of Axle Assembly)

409321

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX