Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

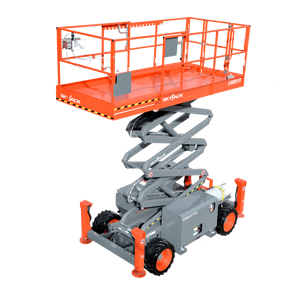

Manual for Skyjack Skyjack Telehandler SJ1256 THS SJ1256 THS

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Skyjack Skyjack Telehandler SJ1256 THS SJ1256 THS

Create an account to install this asset package.

Maintenance Plans for Skyjack Skyjack Telehandler SJ1256 THS Model SJ1256 THS

Integrate maintenance plans directly into your work orders in MaintainX.

3 Monthly / 250 Hourly E-chain and Hoses Inspection

Boom fully retracted

Servicing windows found on the sides of the boom

Covers removed from the servicing windows

E-chain and hoses examined for damage or wear

Upload a photo of the examined e-chain and hoses

Sign off on the inspection

3 Monthly / 250 Hourly Engine Fuel Filter and Fuel/ Water Separator Replacement

WARNING! The fuel pump high-pressure fuel lines and fuel rail contain very high pressure fuel. Never loosen any fittings while the engine is running. Personal injury and property damage can result

Is the telehandler on a firm level surface?

Is the parking brake applied and the engine shut down with the key removed from the ignition switch?

Is the engine compartment cover unlatched and lifted up?

Is the area around the fuel filter and fuel/water separator clean?

Is a container placed under the filter and separator to collect any escaping fuel when removing them?

Is the water level sensor harness disconnected from the fuel/water separator?

Is the drain plug assembly unscrewed from the bottom of the water separator?

Are the used fuel filter and separator unscrewed and discarded along with any captured spilled fuel?

3 Monthly / 250 Hourly Axle Pivot Bearings and King Pins Greasing

Each axle has two integral pivot assemblies which attach the axle to the frame. Each of the four pivot assemblies requires independent lubrication.

Axle Pivot Bearings. There are remote grease fittings for pivot bearing lubrication. The front axle grease fittings are located on the right front frame rail next to the frame level cylinder.

The rear axle remote grease fittings are located beside the right boom lift cylinder.

Wipe dirt and grease from each remote grease fitting.

Apply 4 shots of grease to each fitting.

Axle King Pins. Each axle has two king pins. Each king pin has an upper and a lower grease fitting (total of 4 king pins on each axle).

Wipe each fitting clean.

Apply 4 shots of grease to each fitting.

Sign off on the axle pivot bearings and king pins greasing.

1 Daily / 10 Hourly Hydraulic Oil Level Check

Warning: The telehandler must be on level ground and all cylinders retracted when checking oil level.

Is the telehandler on level ground?

Are all cylinders retracted?

Refer to oil sight gauge at rear of tank to check that the hydraulic fluid is between MAX and MIN.

Is the hydraulic fluid between MAX and MIN?

If not, add clean hydraulic oil through the tank filler as required.

Sign off on the hydraulic oil level check

3 Monthly / 250 Hourly Bottom Front & Top Rear Slide Pads Greasing

Telehandler parked on a firm level surface

Transmission lever moved to neutral and park brake engaged

Boom fully extended to gain access to front bottom slide pads

Engine shut down and dismounted from cab

Grease smeared along the path of front bottom slide pads

Boom fully retracted then fully extended a few times to ensure the path of slide pads is covered with grease for maximum protection

Boom fully retracted, boom rear cover door removed to gain access to top rear slide pads

Grease smeared along the path of rear top slide pads

Engine shut down and key removed

Parts for Skyjack Skyjack Telehandler SJ1256 THS SJ1256 THS

Access the parts list for your equipment in MaintainX.

Washer, Flat 1/4''

103995

Cover, Battery Access

191389

Plate, Cover 4D

190217

Cover, TH LH Side

191397

Cover, Top Rear RH

205727

Washer, Flat 1/4''

103995

Cover, Battery Access

191389

Plate, Cover 4D

190217

Cover, TH LH Side

191397

Cover, Top Rear RH

205727

Washer, Flat 1/4''

103995

Cover, Battery Access

191389

Plate, Cover 4D

190217

Cover, TH LH Side

191397

Cover, Top Rear RH

205727

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX