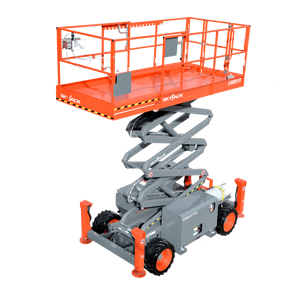

The Skyjack Telehandler SJ1056 THS is a robust and versatile piece of equipment designed for lifting and moving materials in various industrial applications. Known for its reliability and ease of use, this telehandler offers exceptional performance and maneuverability, making it an ideal choice for construction and maintenance tasks.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Skyjack Telehandler SJ1056 THS

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Skyjack Telehandler SJ1056 THS

Create an account to install this asset package.

Maintenance Plans for Skyjack Telehandler Model SJ1056 THS

Integrate maintenance plans directly into your work orders in MaintainX.

3 Monthly / 250 Hourly E-chain and Hoses Inspection

Boom fully retracted

Servicing windows found on the sides of the boom

Covers removed from the servicing windows

E-chain and hoses examined for damage or wear

Upload a photo of the e-chain and hoses

Sign off on the e-chain and hoses inspection

1 Daily / 10 Hourly Coolant Level, Radiator and Hoses Check

WARNING! Pressurized fluid present in radiator. Never open radiator cap when hot

NOTE! Do not intermix different brands of coolant. If the existing coolant cannot be identified, drain and flush the remaining coolant and refill with new coolant. Refer to section 5.4-5 for instructions on changing engine coolant

Radiator cap removed

Radiator filled completely through the radiator neck, until coolant is visible

Enter the time engine was run without radiator cap to achieve operating temperature

Engine shut down

Coolant level and coolant strength in the radiator checked. Mixture adjusted as required. Refilled until coolant is visible

Radiator cap tightened, engine started, and checked for leaks

Sign off on the coolant level, radiator and hoses check

Hydraulic Pressure Test

IMPORTANT! All checks and adjustments are to be made with the engine running at low idle, the transmission shifter in Neutral and the parking brake applied

CAUTION! The addition of a hydraulic accumulator on this system causes residual pressure to be present AFTER the engine has been turned OFF. Prior to opening any hydraulic fitting in this system, move the joystick several times in each direction to relieve this residual pressure. Failure to do so may result in personal injury

Load Sense Compensator Pressure Check

Load Sense Compensator Pressure Reading

Load Sense Compensator Adjustment

System Pressure (Compensator Pressure) Check

System Pressure (Compensator Pressure) Reading

System Pressure (Compensator Pressure) Adjustment

Steering Pressure Check

Slide Pads Replacement

Warning: This procedure requires trained personnel with PPE!

Slide pads are designed to protect the structural integrity of the boom sections. They partially carry the weight of the boom sections and will wear out over time and based on daily operation. Ensure to check slide pads quarterly.

NOTE! The wear pads located at the rear-top and bottom-front of the boom sections wear faster than the other wear pads. The basic procedure for removing wear pads is the same regardless of their location in the boom assembly.

IMPORTANT! Pay attention to high-load slide pads (Front-Lower & Rear-Upper of boom) as most of the weight is exerted on them.

Fully retract the boom

Remove the rear cover from the outer boom

Remove screw, wear pad, shims, and spacer from the boom. For ease of installation, keep all parts that were removed together as an assembly.

Before removing the screws from the wear pads, use a pry bar under the shims of the side wear pads. The bar prevents the shims from falling when the screws are removed.

Remove the screws, shims, and wear pads while holding the bar under the shim. For easier installation, keep all parts removed together as an assembly.

Boom Hoses and Sheaves Replacement

Park telehandler on a firm level surface, apply park brake

Fully retract and lower the boom then shutdown engine and remove key from ignition switch

Remove the rear boom cover

Remove the 2 bolts holding each sheave guard bracket to the finger weldment

Using a allen key or pipe-wrench remove shoulder screw holding the rollers in place

Slowly remove hose sheaves (rollers) and keep thrust washers intact in the same order

Remove end of Fork Tilt hoses at front bulkheads on main boom assembly

Cap/plug all open lines and fittings

Remove other end of Auxilliary Hydraulics hoses at front bulkheads on main boom assembly

Parts for Skyjack Telehandler SJ1056 THS

Access the parts list for your equipment in MaintainX.

Relay, Top Wiper

9-931298

Relay, Power Relay

9-921734

Relay, Glow Plug

9-165029

Fuse, Auxiliary Hydraulics (5A)

9-156202

Fuse, Blower Motor (30A)

9-156164

Relay, Top Wiper

9-931298

Relay, Power Relay

9-921734

Relay, Glow Plug

9-165029

Fuse, Auxiliary Hydraulics (5A)

9-156202

Fuse, Blower Motor (30A)

9-156164

Relay, Top Wiper

9-931298

Relay, Power Relay

9-921734

Relay, Glow Plug

9-165029

Fuse, Auxiliary Hydraulics (5A)

9-156202

Fuse, Blower Motor (30A)

9-156164

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX