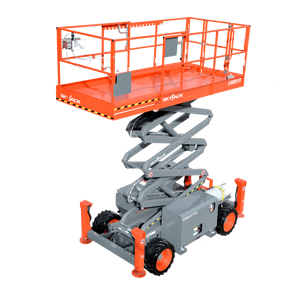

The Skyjack Telehandler SJ1044 THS is a versatile and robust piece of equipment designed for lifting and moving materials in various industrial settings. Known for its reliability and ease of use, this telehandler is ideal for construction and maintenance tasks, ensuring optimal performance and safety on the job site.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Skyjack Telehandler SJ1044 THS

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Skyjack Telehandler SJ1044 THS

Create an account to install this asset package.

Maintenance Plans for Skyjack Telehandler Model SJ1044 THS

Integrate maintenance plans directly into your work orders in MaintainX.

3 Monthly / 250 Hourly Boom Chains Tension Check

Warning: Proper adjustment of the chains at this interval minimizes the risk of chain failure which could cause extensive damage to other boom components and require extensive labor hours to repair.

NOTE! If the chains make noise such as banging on the interior boom parts, or the chain slack identified below is more than the maximum acceptable value, adjustment is necessary.

Telehandler parked on firm level ground and parking brake applied?

Boom fully extended making sure the extend chain on top of boom assembly is visible?

As you retract the boom slowly, any sagging parts or loose links observed?

Enter the chain slack measurement

NOTE! Chain slack should not exceed 1 inch.

Sign off on the boom chains tension check

1 Yearly / 1000 Hourly RAS System Functionality Inspection

WARNING! This procedure must be performed by a qualified service personnel only. Failure to adhere to the steps outlined below could result in serious injury

Ensure park brake is engaged, transmission shifter in neutral, boom fully retracted and above ground

Remove the cover form the RAS manifold and set aside

Unplug all harness connectors from RAS manifold

Sit in the driver’s seat and fasten seat belt

Frame level left and observe the front left wheel lifting off the ground

Observe the front left wheel while it is off the ground for 30 seconds. Ensure that it holds in position

Level the frame to the right until front left tire fully rests on the ground

Shutdown engine and remove key from ignition switch

3 Monthly / 250 Hourly Hydraulic Tank Breather Cleaning

Area around hydraulic breather cleaned

Breather removed and cleaned with solvent

Breather blow dried with compressed air

Cleaned breather installed on the tank

Sign off on the breather cleaning

1 Yearly / 1000 Hourly Axle Differential Oil Change

WARNING! Hot oil or components can burn. Oil must be at normal operating temperature when draining. Avoid contact with hot oil or components. Do not allow oil to drain into the ground.

Axle differential oil is at normal operating temperature

Machine is parked on a firm level surface, parking brake applied, machine shut off, and allowed to sit for two minutes

Container capable of holding approximately 10 quarts (9.5 litres) is placed under axle drain plugs

Areas around the three (3) drain plugs and level/fill plug are cleaned

Level/fill plug is removed

All three (3) drain plugs are removed and oil is drained from the differential

Used oil is disposed of in accordance with local regulations

Magnetic drain plugs are wiped off with a clean rag and installed in the axle

3 Monthly / 250 Hourly Boom Slide Pad Clearances Check

Warning: This procedure requires trained personnel with PPE!

Slide pads support the boom components as the boom is extended and retracted

Clearance between the contact surface of the pad and the adjacent sliding surface

Slide pads are chamfered on the corner of the wear surface

Additional wear will allow interference with inserts in the pads

Lubrication of the pads require application of grease on the boom surfaces which come in contact with the pads

Telehandler parked on a firm level surface

Boom extended and forks rested on a level surface

Park brake applied then engine shutdown and key removed from ignition switch

Parts for Skyjack Telehandler SJ1044 THS

Access the parts list for your equipment in MaintainX.

Fuse, Heater Valve & A/C (10A)

9-156203

Relay, Boom Up

9-931298

Relay, Frame Level Enable

9-931298

Relay, Brake Lamp

9-931298

Fuse, ECM (30A)

9-156164

Fuse, Heater Valve & A/C (10A)

9-156203

Relay, Boom Up

9-931298

Relay, Frame Level Enable

9-931298

Relay, Brake Lamp

9-931298

Fuse, ECM (30A)

9-156164

Fuse, Heater Valve & A/C (10A)

9-156203

Relay, Boom Up

9-931298

Relay, Frame Level Enable

9-931298

Relay, Brake Lamp

9-931298

Fuse, ECM (30A)

9-156164

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX