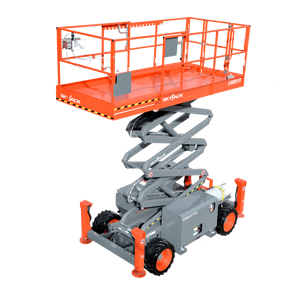

The Skyjack Telehandler SJ1044 TH is a versatile and robust piece of industrial equipment designed for lifting and moving materials on construction sites. Known for its reliability and ease of use, this telehandler offers exceptional performance and maneuverability, making it an essential tool for various lifting applications.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Skyjack Telehandler SJ1044 TH

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Skyjack Telehandler SJ1044 TH

Create an account to install this asset package.

Maintenance Plans for Skyjack Telehandler Model SJ1044 TH

Integrate maintenance plans directly into your work orders in MaintainX.

Boom Chains Replacement

Remove Extend Chain

Partially extend the boom

Remove jam nut at the chain anchor using a 1-1/4” wrench

Remove hex nut using a 1-1/4” wrench

Remove and discard washer

Slide chain anchor through hole on main boom then lay chain with anchor on top of boom

Remove cotter pin and anchor pin then disconnect chain from anchor

Remove rear access cover plate then remove the rear anchor mount on 3rd boom section and/or fourth boom section for SJ1056 TH/THS / SJ1256 THS

Remove cotter pin and anchor pin then disconnect chain from anchor

1 Daily / 10 Hourly Hydraulic Oil Level Check

Warning: The telehandler must be on level ground and all cylinders retracted when checking oil level

Is the telehandler on level ground?

Are all cylinders retracted?

Refer to oil sight gauge at rear of tank to check that the hydraulic fluid is between MAX and MIN

Is the hydraulic fluid between MAX and MIN?

If not, add clean hydraulic oil through the tank filler as required

Sign off on the hydraulic oil level check

1 Daily / 10 Hourly Air Cleaner Restriction and Filter Elements Check

Red band appears on the service indicator

Air cleaner vaccuator valve is clean and rubber is not cracked

Valve lips are free of dirt or dust

Engine expels dust and dirt continuously when running

Condition of primary and safety elements inspected

Primary element replaced or cleaned

Secondary element replaced (cannot be cleaned)

Secondary element replaced after every third cleaning of the primary element or annually

Latches undone and cover removed

3 Monthly / 250 Hourly Torque Axle Mounting Bolts Adjustment

Warning: This procedure requires trained personnel with PPE!

Front axle mounting bolts torqued to 660 lb.ft. (895 N·m)?

Rear axle mounting bolts torqued to 380 lb.ft. (515 N·m)?

Sign off on the torque axle mounting bolts adjustment

3 Monthly / 250 Hourly Axle Pivot Bearings and King Pins Greasing

Each axle has two integral pivot assemblies which attach the axle to the frame. Each of the four pivot assemblies requires independent lubrication

Axle Pivot Bearings. There are remote grease fittings for pivot bearing lubrication. The front axle grease fittings are located on the right front frame rail next to the frame level cylinder

The rear axle remote grease fittings are located beside the right boom lift cylinder

Wipe dirt and grease from each remote grease fitting

Apply 4 shots of grease to each fitting

Axle King Pins. Each axle has two king pins. Each king pin has an upper and a lower grease fitting (total of 4 king pins on each axle)

Wipe each fitting clean

Apply 4 shots of grease to each fitting

Sign off on the axle pivot bearings and king pins greasing

Parts for Skyjack Telehandler SJ1044 TH

Access the parts list for your equipment in MaintainX.

Relay, Carriage Tilt Enable

9-931298

Relay, Power Relay

9-921734

Relay, Frame Level Disable

9-931298

Relay, Engine Running

9-931298

Relay, Frame Level Enable

9-931298

Relay, Carriage Tilt Enable

9-931298

Relay, Power Relay

9-921734

Relay, Frame Level Disable

9-931298

Relay, Engine Running

9-931298

Relay, Frame Level Enable

9-931298

Relay, Carriage Tilt Enable

9-931298

Relay, Power Relay

9-921734

Relay, Frame Level Disable

9-931298

Relay, Engine Running

9-931298

Relay, Frame Level Enable

9-931298

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX