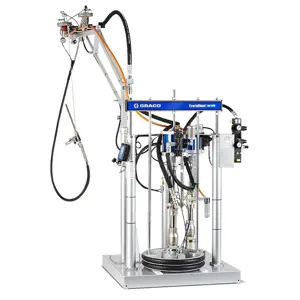

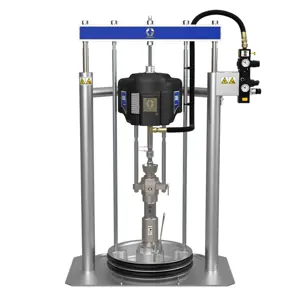

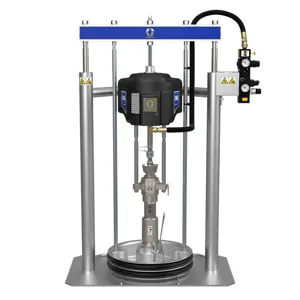

The Graco Proportioner 259026 is a high-performance industrial equipment designed for precise fluid dispensing. This versatile proportioner is ideal for various applications, ensuring efficient operation and reliability in demanding environments. Regular maintenance is essential to maximize its lifespan and performance.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Graco Proportioner 259026

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Graco Proportioner 259026

Create an account to install this asset package.

Maintenance Plans for Graco Proportioner Model 259026

Integrate maintenance plans directly into your work orders in MaintainX.

1 Monthly Pump Lubricant Replacement

Pump Lubrication System

Check the condition of the ISO pump lubricant daily.

Change the lubricant if it becomes a gel, its color darkens, or it becomes diluted with isocyanate.

Gel formation is due to moisture absorption by the pump lubricant.

The interval between changes depends on the environment in which the equipment is operating.

The pump lubrication system minimizes exposure to moisture, but some contamination is still possible.

Lubricant discoloration is due to continual seepage of small amounts of isocyanate past the pump packings during operation.

If the packings are operating properly, lubricant replacement due to discoloration should not be necessary more often than every 3 or 4 weeks.

To change pump lubricant:

1 Daily Proportioner Inspection

Check hoses and couplings

Check equipment

Component B (Resin) Pump: Check felt washers in packing nut/wet-cup (S)

Check wet cup TSL level

Inspect fluid inlet strainer screens

Inspect ISO lubricant level and condition

Keep component A from exposure to moisture in atmosphere to prevent crystallization

Clean gun mix chamber ports

Clean gun check valve screens

Fluid Inlet Strainer Screen Maintenance

Fluid Inlet Strainer Screen

The inlet strainers filter out particles that can plug the pump inlet check valves. Inspect the screens daily as part of the startup routine, and clean as required.

Use clean chemicals and follow proper storage transfer and operating procedures to minimize contamination of the A-side screen.

NOTE Clean the A-side screen only during daily startup. This minimizes moisture contamination by immediately flushing out any isocyanate residue at the start of dispensing operations.

1. Close the fluid inlet valve at the pump inlet and shut off the appropriate feed pump. This prevents material from being pumped while cleaning the screen.

2. Place a container under the strainer manifold 59d to catch fluid. Remove the strainer plug 59j.

3. Remove the screen 59g from the strainer manifold. Thoroughly flush the screen with compatible solvent and shake it dry. Inspect the screen. If more than 25 percent of the mesh is blocked replace the screen. Inspect the gasket 59h and replace as required.

4. Ensure the pipe plug 59k is screwed into the strainer plug 59j. Install the strainer plug with the screen 59g and gasket 59h in place and tighten. Do not overtighten. Let the gasket make the seal.

5. Open the fluid inlet valve ensure that there are no leaks and wipe the equipment clean. Proceed with operation.;

Parts for Graco Proportioner 259026

Access the parts list for your equipment in MaintainX.

Conversion Kit

248669

Throat Seal Liquid

206995

Return Tube Kit

246477

Fusion Grease

117773

Data Reporting Kit w/o Interface Module

248848

Conversion Kit

248669

Throat Seal Liquid

206995

Return Tube Kit

246477

Fusion Grease

117773

Data Reporting Kit w/o Interface Module

248848

Conversion Kit

248669

Throat Seal Liquid

206995

Return Tube Kit

246477

Fusion Grease

117773

Data Reporting Kit w/o Interface Module

248848

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX