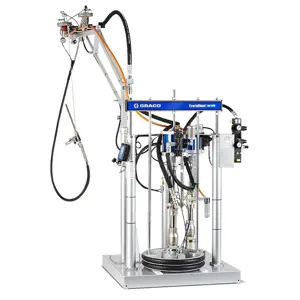

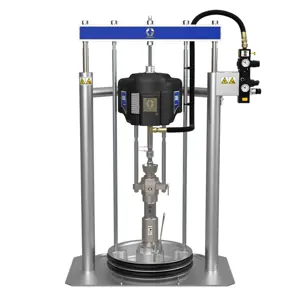

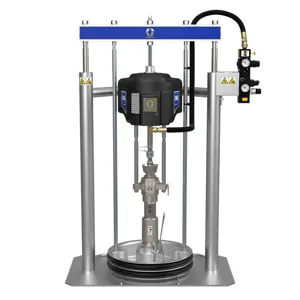

The Graco Hot Melt Delivery System 24P265 is a reliable industrial asset designed for efficient adhesive application. This system ensures precise temperature control and consistent material flow, making it ideal for various manufacturing processes. Enhance your production line with Graco's advanced technology and robust performance.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Graco Hot Melt Delivery System 24P265

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Graco Hot Melt Delivery System 24P265

Create an account to install this asset package.

Maintenance Plans for Graco Hot Melt Delivery System Model 24P265

Integrate maintenance plans directly into your work orders in MaintainX.

4 Monthly Inlet Filter Replacement

Warning: To avoid severe burns wear protective gloves and clothing that will insulate your hands and body from the hot surfaces and material.

System air inlet ball valve closed

Enter the current temperature of the melter

Heating system disabled if melter is below the desired temperature

Heating system enabled if melter is above the desired temperature

Melter temperature is the desired temperature

Main power switch turned OFF when melter temperature is the desired temperature

Cable disconnected from ADM and plastic shroud removed from system

Cardboard placed beneath the inlet filter cap to route fluid away from system into a waste container

4 Monthly Outlet Filter Replacement

Warning: To avoid severe burns wear protective gloves and clothing that will insulate your hands and body from the hot surfaces and material.

System up to temperature

If the system is not up to temperature press power button to enable the heaters and pump then wait for system to reach operating temperature.

Performed Pressure Relief Procedure

Do not allow system to cool. Adhesive must be a fluid to perform this procedure.

Main power switch turned OFF

Loosened two screws (8) then slid the small metal shroud (28) on the back of the system up to remove

Used a 1 in socket to unscrew outlet filter (236)

Inserted allen wrench through the outlet filter cap to lift outlet filter (236) out of the system

4 Monthly Funnel Filter Replacement

Disassembly

1. Turn main power switch OFF.

2. Loosen and remove the two phillips head screws on the side of the funnel then remove the funnel cap.

3. Remove and replace foam filter.

Reassembly

1. Place funnel cap onto funnel.

2. Install two phillips head screws to secure funnel cap to funnel base. ;

4 Monthly Filters Maintenance

Warning: This maintenance check requires trained personnel with PPE!

Replace the following filters

Feed Funnel inspected and cleaned out?

These recommendations are service level guidelines - actual service levels required in your factory will vary based on environmental and operating conditions.

High or low volume adhesive usage as well as adhesives that contain a powered release agent or are otherwise dusty will have an impact on the frequency of filter maintenance.

To establish a preventative maintenance cycle tailored to your environment Graco recommends inspecting filters every 4 weeks after installation and replacing when necessary.

Document replacement intervals and use this as your preventative maintenance schedule moving forward.

Sign off on the filter maintenance

Parts for Graco Hot Melt Delivery System 24P265

Access the parts list for your equipment in MaintainX.

MZLP Fuse, 250VAC, 25A, Fast Acting, White, 0.25 in x 1.2 in

24V510

Fuse Kit w/Standard Clear Fuses (2)

24V289

Air Filter Kit

24R707

Adhesive Pellets Container

24R136

InvisiPac Software Upgrade Token

24R324

MZLP Fuse, 250VAC, 25A, Fast Acting, White, 0.25 in x 1.2 in

24V510

Fuse Kit w/Standard Clear Fuses (2)

24V289

Air Filter Kit

24R707

Adhesive Pellets Container

24R136

InvisiPac Software Upgrade Token

24R324

MZLP Fuse, 250VAC, 25A, Fast Acting, White, 0.25 in x 1.2 in

24V510

Fuse Kit w/Standard Clear Fuses (2)

24V289

Air Filter Kit

24R707

Adhesive Pellets Container

24R136

InvisiPac Software Upgrade Token

24R324

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX